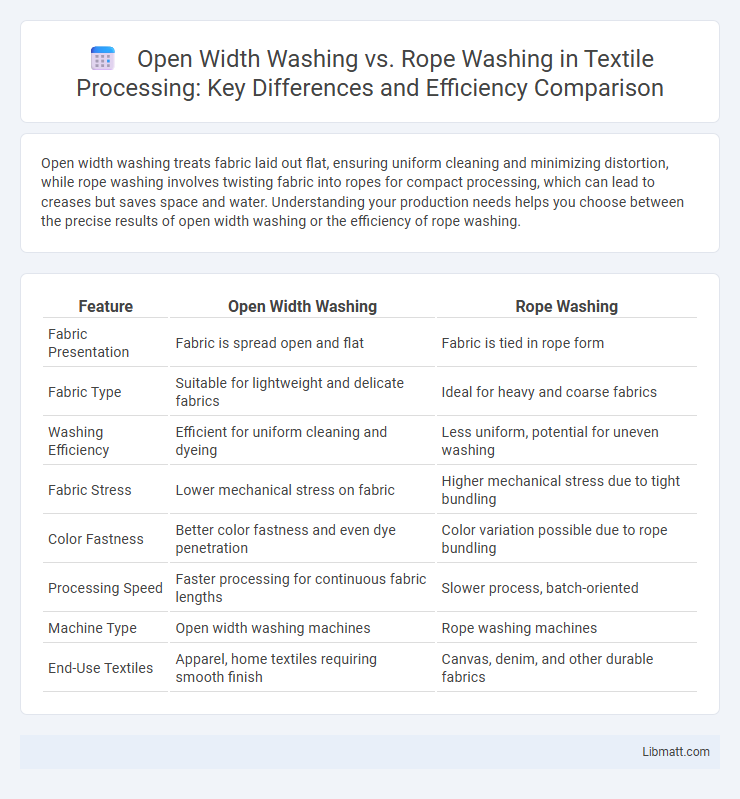

Open width washing treats fabric laid out flat, ensuring uniform cleaning and minimizing distortion, while rope washing involves twisting fabric into ropes for compact processing, which can lead to creases but saves space and water. Understanding your production needs helps you choose between the precise results of open width washing or the efficiency of rope washing.

Table of Comparison

| Feature | Open Width Washing | Rope Washing |

|---|---|---|

| Fabric Presentation | Fabric is spread open and flat | Fabric is tied in rope form |

| Fabric Type | Suitable for lightweight and delicate fabrics | Ideal for heavy and coarse fabrics |

| Washing Efficiency | Efficient for uniform cleaning and dyeing | Less uniform, potential for uneven washing |

| Fabric Stress | Lower mechanical stress on fabric | Higher mechanical stress due to tight bundling |

| Color Fastness | Better color fastness and even dye penetration | Color variation possible due to rope bundling |

| Processing Speed | Faster processing for continuous fabric lengths | Slower process, batch-oriented |

| Machine Type | Open width washing machines | Rope washing machines |

| End-Use Textiles | Apparel, home textiles requiring smooth finish | Canvas, denim, and other durable fabrics |

Introduction to Textile Washing Methods

Open width washing involves processing textiles laid flat and spread out, ensuring uniform exposure to water and chemicals, which is ideal for delicate fabrics and maintaining fabric width. Rope washing treats textiles in rope form, allowing efficient bulk washing and softening, often used for denser or heavier materials requiring thorough treatment. Both methods optimize washing effectiveness based on fabric type, with open width preserving fabric structure and rope washing enhancing dye fixation and fiber cleaning.

What is Open Width Washing?

Open width washing is a textile cleaning process where fabric is treated in a flat, spread-out form rather than being rolled or rope-like. This method ensures uniform cleaning and dyeing by exposing the entire fabric surface to water, chemicals, and mechanical action evenly. You benefit from improved fabric quality and reduced risk of defects such as creases or uneven treatment during open width washing.

What is Rope Washing?

Rope washing is a textile cleaning process where yarns are gathered into long strands or "ropes" and cleaned before fabric formation, enhancing uniformity and reducing tension-related defects. This method improves dye penetration and color consistency compared to open width washing, which treats fabric in its flat form. Rope washing is preferred for delicate or high-quality yarns to ensure better fabric appearance and performance.

Key Differences Between Open Width and Rope Washing

Open width washing involves spreading fabric in a flat, open form through the washing machine, allowing for uniform treatment and efficient processing of delicate materials. Rope washing entangles fabric strips into a rope-like bundle, enabling deeper penetration of chemicals and water, making it ideal for heavy stains and denser textiles. The key differences include fabric presentation (flat vs. bundled), washing intensity, and suitability for various fabric types and soil levels.

Advantages of Open Width Washing

Open width washing offers significant advantages such as uniform cleaning and efficient chemical application, ensuring your fabrics are thoroughly treated without distortion. This method reduces fabric tension and creasing compared to rope washing, preserving material quality and enhancing overall textile performance. The increased process control in open width washing leads to consistent results, minimizing shrinkage and optimizing fabric appearance.

Benefits of Rope Washing

Rope washing uses fabric twisted into ropes, allowing deeper detergent penetration and more consistent cleaning compared to open width washing. This method reduces mechanical stress on the fabric, minimizing damage and enhancing fabric strength and durability. Rope washing is particularly effective for delicate fabrics and complex dye patterns, ensuring vibrant and uniform colors.

Challenges and Limitations of Open Width Washing

Open width washing faces challenges such as uneven water distribution, leading to inconsistent fabric cleaning and potential damage to delicate textiles. The process often requires higher water and chemical consumption compared to rope washing, impacting sustainability and cost-efficiency. Limited fabric tension control in open width washing can result in shrinkage or distortion, reducing overall product quality.

Drawbacks of Rope Washing

Rope washing often results in uneven fabric tension, causing inconsistent dyeing or washing effects that can compromise garment quality. This method restricts fabric width, limiting production efficiency and increasing processing time compared to open width washing. You may experience higher chances of fabric creasing and reduced surface exposure, which can impact the overall finish of your textile products.

Choosing the Right Washing Method for Your Fabric

Open width washing ensures even cleaning and better fabric quality by spreading textiles flat during the process, ideal for delicate or lightweight materials. Rope washing, where fabric is twisted into ropes, suits heavier or more durable fabrics, allowing for greater mechanical action and cost efficiency. Understanding your fabric's weight, texture, and desired finish will help you choose the optimal washing method for your specific needs.

Conclusion: Open Width Washing vs Rope Washing

Open width washing offers superior fabric quality with less distortion and more uniform treatment, making it ideal for delicate or high-end textiles. Rope washing is more economical and suitable for bulk processing of durable fabrics but may cause more creases and uneven washing. Choosing between open width and rope washing depends on fabric type, desired quality, and production efficiency requirements.

Open width washing vs Rope washing Infographic

libmatt.com

libmatt.com