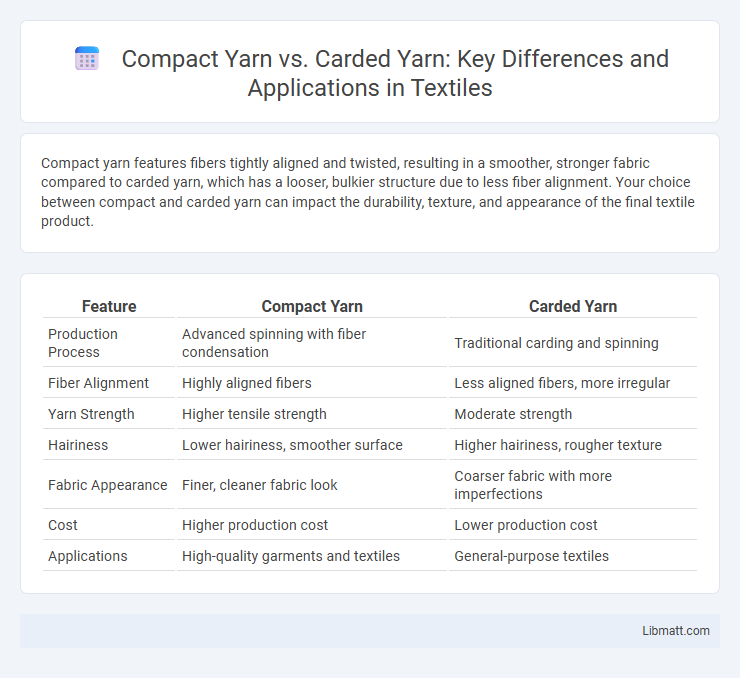

Compact yarn features fibers tightly aligned and twisted, resulting in a smoother, stronger fabric compared to carded yarn, which has a looser, bulkier structure due to less fiber alignment. Your choice between compact and carded yarn can impact the durability, texture, and appearance of the final textile product.

Table of Comparison

| Feature | Compact Yarn | Carded Yarn |

|---|---|---|

| Production Process | Advanced spinning with fiber condensation | Traditional carding and spinning |

| Fiber Alignment | Highly aligned fibers | Less aligned fibers, more irregular |

| Yarn Strength | Higher tensile strength | Moderate strength |

| Hairiness | Lower hairiness, smoother surface | Higher hairiness, rougher texture |

| Fabric Appearance | Finer, cleaner fabric look | Coarser fabric with more imperfections |

| Cost | Higher production cost | Lower production cost |

| Applications | High-quality garments and textiles | General-purpose textiles |

Introduction to Compact Yarn and Carded Yarn

Compact yarn is produced using a spinning technology that condenses fibers before twisting, resulting in stronger, smoother, and less hairy yarn with improved fabric quality. Carded yarn is made by carding fibers to align and clean them before spinning, producing a coarser, less uniform yarn suitable for heavier textiles and casual wear. Both yarn types cater to different fabric requirements, with compact yarn offering enhanced strength and appearance compared to the traditional carded yarn.

Manufacturing Processes Compared

Compact yarn is produced using a special drafting system that condenses fibers before twisting, resulting in fewer protruding fibers and enhanced strength compared to carded yarn, which is made by carding fibers together without the additional condensation step. The compact spinning process reduces yarn hairiness and improves uniformity, while carded yarn involves a more basic fiber alignment method that leaves more neps and irregularities. Your choice between compact and carded yarn manufacturing affects fabric durability, smoothness, and overall quality.

Fiber Alignment and Structure Differences

Compact yarn features tightly aligned fibers achieved through an advanced spinning process that reduces hairiness and increases strength, resulting in a smoother, more uniform structure. Carded yarn, created by carding fibers loosely, has a more open and uneven fiber arrangement, which leads to a softer but less durable yarn with more surface fuzz. Understanding these fiber alignment and structural differences can help you choose the right yarn for your textile projects, balancing strength and texture requirements.

Physical Properties: Strength and Evenness

Compact yarn demonstrates superior tensile strength and enhanced evenness compared to carded yarn, owing to its fiber alignment and reduced hairiness during spinning. The compact process condenses fibers, minimizing air entrapment and resulting in yarn that is both stronger and smoother with fewer thin and thick spots. Your textile products benefit from increased durability and a more uniform appearance when using compact yarn over traditional carded yarn.

Surface Appearance and Handle

Compact yarn features a smoother surface appearance due to the reduction of hairiness achieved by the compaction process, resulting in a tighter fiber alignment. The handle of compact yarn is softer and more uniform compared to carded yarn, providing enhanced fabric comfort and durability. Carded yarn, with its looser fiber arrangement, tends to have a rougher texture and a bulkier feel, impacting the final fabric's surface smoothness and tactile quality.

Performance in Weaving and Knitting

Compact yarn exhibits higher strength and reduced hairiness compared to carded yarn, enhancing weaving efficiency and minimizing fabric defects. The uniform fiber alignment in compact yarn leads to smoother yarn surfaces, resulting in improved fabric appearance and better knitability. Carded yarns, while more cost-effective, tend to produce rougher textures and lower tensile strength, which may affect the consistency and durability of woven and knitted fabrics.

Quality and End-Use Applications

Compact yarn offers superior quality with smoother surface, higher tensile strength, and reduced hairiness compared to carded yarn, making it ideal for premium textiles requiring enhanced durability and softness. Carded yarn, while less refined, provides a cost-effective solution suitable for everyday apparel, home textiles, and products where comfort is prioritized over high performance. Your choice between compact and carded yarn should align with the desired fabric aesthetics and functional requirements of the end-use application.

Cost Implications and Economic Considerations

Compact yarn manufacturing involves higher initial investment due to advanced machinery and technology, leading to increased production costs compared to carded yarn. However, the improved yarn strength, reduced hairiness, and better fabric quality of compact yarn can result in lower wastage and higher-value end products, potentially offering better long-term economic benefits. Your choice between compact and carded yarn should weigh the upfront cost against the expected improvements in durability and fabric performance to optimize overall cost efficiency.

Environmental Impact and Sustainability

Compact yarn production reduces fiber waste by drawing fibers closer together, enhancing yarn strength and fabric durability, which leads to longer-lasting textiles and less frequent replacement. Carded yarn, typically involving more fiber ends protruding, results in higher fiber loss during spinning and requires more energy-consuming processing stages. Choosing compact yarn helps lower carbon emissions and resource consumption, making it a more sustainable option compared to traditional carded yarns.

Choosing the Right Yarn for Your Needs

Choosing the right yarn depends on the specific requirements of your project. Compact yarn offers increased strength, reduced hairiness, and smoother fabric appearance, ideal for high-quality garments requiring durability. Carded yarn is more affordable with a softer texture, suitable for everyday wear and less demanding applications where budget and comfort are priorities.

Compact Yarn vs Carded Yarn Infographic

libmatt.com

libmatt.com