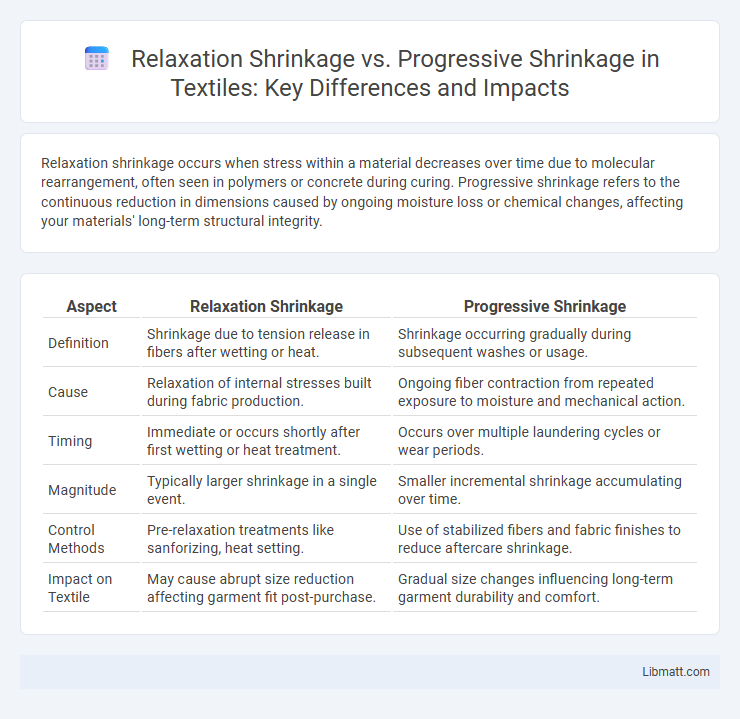

Relaxation shrinkage occurs when stress within a material decreases over time due to molecular rearrangement, often seen in polymers or concrete during curing. Progressive shrinkage refers to the continuous reduction in dimensions caused by ongoing moisture loss or chemical changes, affecting your materials' long-term structural integrity.

Table of Comparison

| Aspect | Relaxation Shrinkage | Progressive Shrinkage |

|---|---|---|

| Definition | Shrinkage due to tension release in fibers after wetting or heat. | Shrinkage occurring gradually during subsequent washes or usage. |

| Cause | Relaxation of internal stresses built during fabric production. | Ongoing fiber contraction from repeated exposure to moisture and mechanical action. |

| Timing | Immediate or occurs shortly after first wetting or heat treatment. | Occurs over multiple laundering cycles or wear periods. |

| Magnitude | Typically larger shrinkage in a single event. | Smaller incremental shrinkage accumulating over time. |

| Control Methods | Pre-relaxation treatments like sanforizing, heat setting. | Use of stabilized fibers and fabric finishes to reduce aftercare shrinkage. |

| Impact on Textile | May cause abrupt size reduction affecting garment fit post-purchase. | Gradual size changes influencing long-term garment durability and comfort. |

Understanding Fabric Shrinkage: An Overview

Fabric shrinkage occurs due to the relaxation of stresses in fibers during washing or wear, referred to as relaxation shrinkage, which primarily affects the fabric's length and width. Progressive shrinkage happens over multiple washes, progressively reducing fabric size as fibers continue to contract and realign. Understanding these distinctions helps you manage garment care to maintain fabric dimensions and prolong clothing lifespan.

What Is Relaxation Shrinkage?

Relaxation shrinkage refers to the reduction in volume or deformation of materials, such as concrete or polymers, occurring when internal stresses decrease over time without external loading. It primarily results from the gradual stress relaxation within the material's molecular or microstructural network, leading to dimensional changes. Understanding relaxation shrinkage is crucial for predicting long-term behavior and ensuring structural integrity in construction and manufacturing applications.

What Is Progressive Shrinkage?

Progressive shrinkage refers to the gradual reduction in volume or size of a material over time due to ongoing chemical reactions or environmental factors, such as hydration in concrete curing. Unlike relaxation shrinkage, which occurs as internal stresses decrease immediately after loading, progressive shrinkage continuously affects your structure's dimensions, leading to long-term deformation. Understanding progressive shrinkage is essential for accurately predicting and managing material behavior in construction and manufacturing.

Key Differences Between Relaxation and Progressive Shrinkage

Relaxation shrinkage occurs immediately after the concrete is placed, caused by the release of internal stresses as it relaxes, whereas progressive shrinkage develops gradually over time due to ongoing moisture loss and chemical reactions. Relaxation shrinkage primarily affects early-age concrete, impacting initial stress distribution, while progressive shrinkage influences long-term volume reduction and cracking potential. Understanding these differences is crucial for effective concrete mix design and structural durability management.

Causes and Mechanisms of Relaxation Shrinkage

Relaxation shrinkage occurs due to the gradual reduction of tensile stresses in concrete as internal stresses relax over time, primarily caused by the viscoelastic behavior of cement paste under sustained loads. This mechanism involves molecular reorganization and microstructural adjustments within the hydrated cement matrix, leading to a decrease in volume without external moisture loss. In contrast, progressive shrinkage results mainly from moisture evaporation and ongoing hydration, whereas relaxation shrinkage depends on stress redistribution and creep deformation.

Triggers and Factors Influencing Progressive Shrinkage

Progressive shrinkage is primarily triggered by continuous exposure to high temperatures and sustained mechanical stress, causing gradual densification and volume reduction in materials over time. Factors influencing this include temperature gradients, material composition, moisture content, and stress distribution, which together accelerate microstructural changes leading to shrinkage. Your understanding of these triggers can help in predicting material behavior and implementing control measures to minimize deformation during prolonged thermal or mechanical loading.

Impact of Shrinkage Types on Fabric Performance

Relaxation shrinkage occurs immediately after the fabric is removed from tension, leading to dimensional changes that can impact garment fit and stability. Progressive shrinkage happens during repeated washing and drying cycles, gradually affecting fabric resilience and elasticity over time. Understanding the distinct effects of relaxation and progressive shrinkage helps in selecting appropriate fabric finishes and treatments to maintain optimal fabric performance and longevity.

Methods to Minimize Relaxation and Progressive Shrinkage

Methods to minimize relaxation shrinkage include using prestressed concrete and controlled curing processes that reduce internal stresses over time. Progressive shrinkage can be mitigated by employing gradual loading techniques and utilizing materials with low creep properties to evenly distribute strain. Your engineering approach should combine appropriate mix designs and structural detailing to effectively control both relaxation and progressive shrinkage for optimal long-term performance.

Industry Applications: Choosing the Right Shrinkage Control

Relaxation shrinkage is crucial in concrete structures where early-age cracking must be minimized, commonly applied in slab-on-grade floors and bridge decks to maintain surface integrity under thermal and moisture changes. Progressive shrinkage dominates in applications requiring long-term dimensional stability, such as high-rise buildings and precast elements, making it essential for engineers to select shrinkage control methods aligned with project lifespan and structural demands. Industry professionals prioritize materials and curing techniques that address the dominant shrinkage type to enhance durability and reduce maintenance costs in construction projects.

Conclusion: Relaxation Shrinkage vs Progressive Shrinkage in Textile Care

Relaxation shrinkage occurs when fibers return to their natural length after the tension of manufacturing or weaving is released, leading to an immediate but limited size reduction. Progressive shrinkage happens over time with repeated laundering or wear, gradually decreasing fabric size due to ongoing fiber contraction and mechanical action. In textile care, understanding these mechanisms helps optimize washing techniques and fabric treatments to maintain garment fit and durability.

Relaxation shrinkage vs Progressive shrinkage Infographic

libmatt.com

libmatt.com