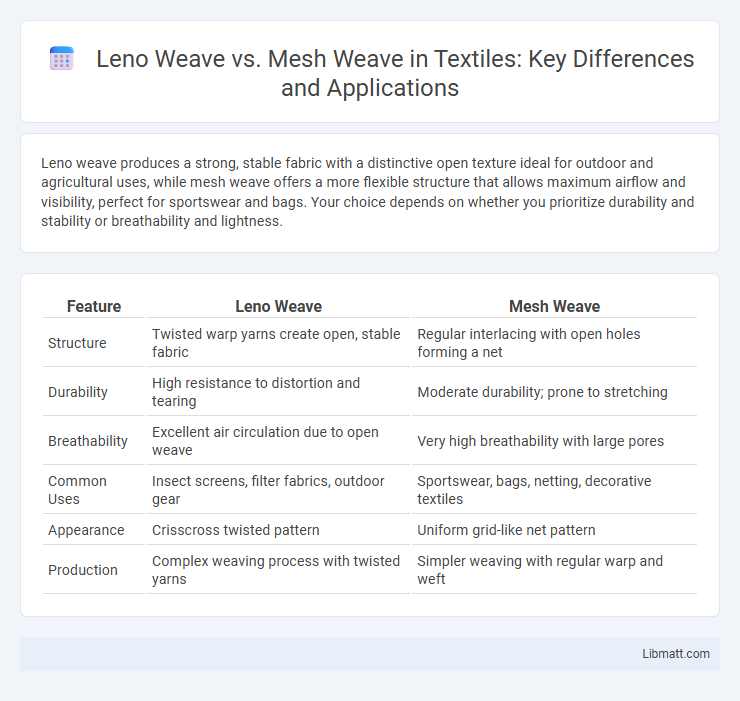

Leno weave produces a strong, stable fabric with a distinctive open texture ideal for outdoor and agricultural uses, while mesh weave offers a more flexible structure that allows maximum airflow and visibility, perfect for sportswear and bags. Your choice depends on whether you prioritize durability and stability or breathability and lightness.

Table of Comparison

| Feature | Leno Weave | Mesh Weave |

|---|---|---|

| Structure | Twisted warp yarns create open, stable fabric | Regular interlacing with open holes forming a net |

| Durability | High resistance to distortion and tearing | Moderate durability; prone to stretching |

| Breathability | Excellent air circulation due to open weave | Very high breathability with large pores |

| Common Uses | Insect screens, filter fabrics, outdoor gear | Sportswear, bags, netting, decorative textiles |

| Appearance | Crisscross twisted pattern | Uniform grid-like net pattern |

| Production | Complex weaving process with twisted yarns | Simpler weaving with regular warp and weft |

Introduction to Leno Weave and Mesh Weave

Leno weave and mesh weave are distinct fabric construction techniques used to create open, airy textiles with enhanced durability. Leno weave involves twisting two warp yarns around the weft yarn, resulting in a strong and stable fabric ideal for applications needing both breathability and strength. Mesh weave features a network-like structure with evenly spaced holes, providing excellent ventilation and flexibility for uses like sportswear and nets.

Defining Leno Weave: Structure and Technique

Leno weave is characterized by its distinctive twisted warp threads that create a strong, open mesh structure ideal for durability and breathability. This technique involves crossing two warp yarns around the weft to lock the threads in place, preventing slippage and fraying. Understanding the leno weave structure helps you choose fabrics that combine stability with ventilation, commonly used in outdoor and industrial textiles.

Understanding Mesh Weave: Features and Formation

Mesh weave features an open, net-like structure created by interlacing warp and weft threads perpendicularly, allowing superior airflow and flexibility. Unlike the denser, crisscross pattern of leno weave, mesh weave forms uniform holes that enhance breathability, making it ideal for applications requiring ventilation and lightweight durability. Your choice of mesh weave ensures optimal performance in sportswear, outdoor gear, or furniture upholstery where comfort and ventilation are crucial.

Comparative Fabric Properties: Leno vs Mesh

Leno weave fabric features a twisted warp yarn structure that enhances durability, reduces slippage, and provides superior resistance to deformation compared to mesh weave, which typically uses a simple over-under pattern offering greater breathability and flexibility. Leno's tightly twisted warps create a stable, open fabric ideal for applications requiring strength and shape retention, while mesh weave excels in lightweight, ventilated textiles suited for activewear and outdoor gear. The distinct structural differences impact tensile strength, stretchability, and air permeability, making leno weave optimal for heavy-duty industrial uses and mesh weave preferable for comfort-focused apparel.

Strength and Durability Analysis

Leno weave offers enhanced strength and durability due to its twisted warp yarns that lock the weft yarns firmly in place, reducing yarn slippage and providing higher resistance to tearing compared to mesh weave. Mesh weave features an open, grid-like structure that allows greater airflow but sacrifices some tensile strength and abrasion resistance. Your choice between leno and mesh weave should consider the balance of durability needs and ventilation requirements for the specific application.

Airflow and Breathability Differences

Leno weave fabric features twisted warp yarns that create an open yet stable structure, enhancing airflow and breathability significantly compared to traditional mesh weave, which uses interlaced yarns forming a tighter pattern. The open construction of leno weave allows superior air circulation, making it ideal for applications requiring moisture wicking and cooling properties. In contrast, mesh weave, though breathable, tends to trap more heat due to its denser design, limiting airflow relative to leno weave.

Common Applications in Industry

Leno weave is commonly used in industrial applications requiring durability and stability, such as agricultural nets, military fabrics, and geotextiles designed to resist tearing and withstand harsh environmental conditions. Mesh weave is frequently utilized in sportswear, outdoor gear, and medical textiles where breathability, lightweight structure, and filtration properties are essential. Your choice depends on whether you need the strong, stable properties of leno weave or the breathable, flexible nature of mesh weave for specific industrial applications.

Visual Appearance and Texture Comparison

Leno weave features a tight, durable fabric with an open, grid-like pattern that offers a crisp texture and a slightly rough surface ideal for airflow and transparency. Mesh weave presents a more flexible, softer texture with larger, uniform holes that create a breathable, net-like appearance commonly used in sportswear and outdoor gear. Visually, leno weave appears more structured and geometric, while mesh weave looks smoother and more elastic, lending distinct tactile and aesthetic qualities to each fabric type.

Advantages and Disadvantages of Each Weave

Leno weave offers superior durability and breathability by locking warp threads with cross-threads, making it ideal for outdoor and industrial textiles but tends to be less flexible and heavier than mesh weave. Mesh weave provides excellent ventilation and lightweight comfort, commonly used in sportswear and netting, yet it lacks the strength and abrasion resistance found in leno weave. Choosing between leno and mesh weave depends on the application requirements for strength, airflow, and fabric stiffness.

Choosing the Right Weave for Your Needs

Leno weave offers superior durability and breathability, making it ideal for heavy-duty applications requiring strength and ventilation, such as outdoor furniture and agricultural netting. Mesh weave provides a lightweight structure with excellent flexibility and visibility, perfect for sportswear, bags, and window screens where comfort and airflow are priorities. Selecting between leno and mesh weaves depends on balancing the need for structural integrity versus lightweight comfort tailored to your specific project requirements.

Leno Weave vs Mesh Weave Infographic

libmatt.com

libmatt.com