Ring spun yarn offers superior strength and softness by twisting fibers tightly together, making it ideal for comfortable, durable fabrics. Open-end yarn production is faster and more cost-effective but produces coarser, less durable yarn, suited for heavier textiles where softness is less critical.

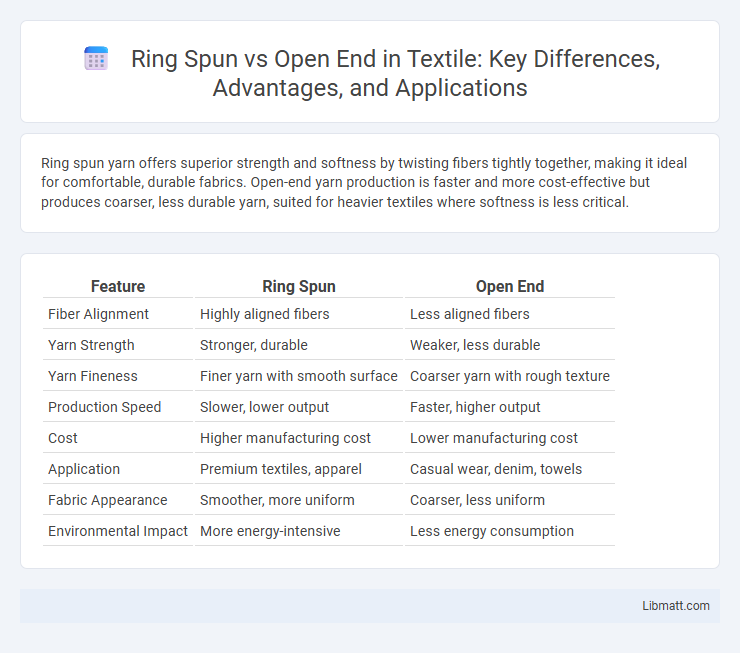

Table of Comparison

| Feature | Ring Spun | Open End |

|---|---|---|

| Fiber Alignment | Highly aligned fibers | Less aligned fibers |

| Yarn Strength | Stronger, durable | Weaker, less durable |

| Yarn Fineness | Finer yarn with smooth surface | Coarser yarn with rough texture |

| Production Speed | Slower, lower output | Faster, higher output |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Application | Premium textiles, apparel | Casual wear, denim, towels |

| Fabric Appearance | Smoother, more uniform | Coarser, less uniform |

| Environmental Impact | More energy-intensive | Less energy consumption |

Introduction to Ring Spun and Open End Yarn

Ring spun yarn is produced by continuously twisting and thinning fibers, resulting in a finer, stronger, and softer textile ideal for high-quality fabrics. Open end yarn is created through a more efficient, rotor spinning process that breaks fibers into shorter lengths, producing coarser, less uniform yarn used primarily for denim and towels. The distinct manufacturing methods impact the yarn's texture, strength, and applications in the textile industry.

Manufacturing Process Differences

Ring spun yarn is produced by continuously twisting and thinning the fiber strands, resulting in smoother and stronger yarn, while open end yarn is made by breaking fibers into shorter lengths and spinning them without twisting. The ring spun process involves more steps, such as carding, drawing, and roving, providing better fiber alignment and tensile strength. Your choice between the two impacts fabric durability and texture due to these fundamental manufacturing differences.

Fiber Quality and Raw Materials

Ring spun yarns use longer, high-quality fibers that result in stronger, softer, and more durable fabrics, ideal for premium garments. Open end yarns utilize shorter fibers and lower-grade raw materials, producing coarser textures suitable for heavy-duty textiles or budget-friendly products. Your choice of fiber quality directly impacts the comfort, longevity, and appearance of the finished fabric.

Structural Characteristics of Yarn

Ring spun yarn exhibits a tightly twisted structure with long, continuous fibers aligned parallel to each other, resulting in higher strength, smoothness, and uniformity. Open end yarn, created by a rotor spinning process, has a coarser, more irregular texture due to shorter fiber lengths and less parallel alignment, leading to lower tensile strength and a bulkier feel. The structural differences significantly impact fabric durability, softness, and abrasion resistance, with ring spun yarn favored for premium quality textiles.

Strength and Durability Comparison

Ring spun yarns exhibit superior strength and durability compared to open end yarns due to their tightly twisted fibers, resulting in higher tensile strength and resistance to abrasion. The continuous fiber alignment in ring spun yarn reduces fiber breakage, enhancing fabric longevity in high-stress applications. While open end yarns offer cost efficiency and faster production, they typically show lower durability and are more prone to pilling and wear over time.

Feel and Texture of the Fabric

Ring spun yarn produces fabric with a smooth, soft feel and a finer texture due to the tightly twisted fibers which enhance durability and comfort. Open end yarn results in a coarser, rougher fabric texture because of the shorter, uneven fibers and the less compact spinning process. The choice between ring spun and open end significantly affects the hand feel and quality perception of cotton textiles.

Applications in Textile Industry

Ring spun yarns are widely used in high-quality textile applications such as premium apparel, denim, and fine knits due to their superior strength, softness, and durability. Open end yarns, characterized by faster production rates and lower cost, are preferred for mass-produced items like towels, denim, and home furnishings where durability and bulkiness are essential. The textile industry leverages ring spun yarns for luxury fabrics requiring fine texture while open end yarns dominate in heavy-duty and cost-sensitive products.

Cost and Production Efficiency

Ring spun yarn typically incurs higher production costs due to its longer processing time and labor intensity, resulting in a finer and stronger yarn quality. Open end spinning offers greater production efficiency with faster manufacturing speeds and lower operational expenses, making it ideal for bulk, cost-sensitive applications. Your choice depends on balancing cost constraints with the desired fabric durability and texture.

Sustainability and Environmental Impact

Ring spun yarn production consumes more water and energy compared to open end spinning, leading to a slightly higher environmental footprint. Open end spinning uses less raw material and generates less waste due to higher fiber utilization efficiency, contributing to better sustainability. However, advancements in technology are reducing the environmental impact of ring spun processes, making both methods increasingly eco-friendly.

Choosing the Right Yarn for Your Needs

Ring spun yarn offers superior strength and softness, making it ideal for high-quality garments requiring durability and comfort. Open-end yarn is more cost-effective and provides a coarser texture, suitable for casual wear and bulk production. Understanding your project's requirements will help you choose the right yarn to balance performance, feel, and budget.

Ring spun vs Open end Infographic

libmatt.com

libmatt.com