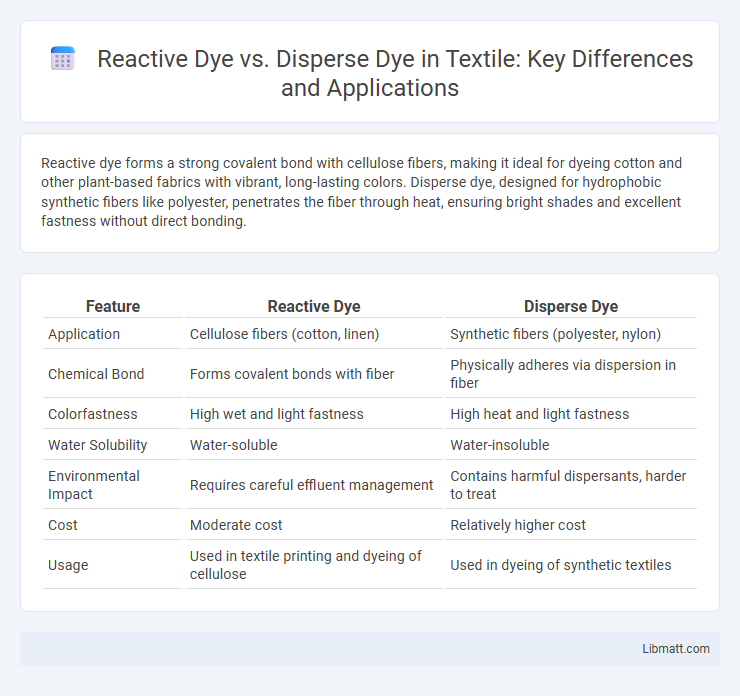

Reactive dye forms a strong covalent bond with cellulose fibers, making it ideal for dyeing cotton and other plant-based fabrics with vibrant, long-lasting colors. Disperse dye, designed for hydrophobic synthetic fibers like polyester, penetrates the fiber through heat, ensuring bright shades and excellent fastness without direct bonding.

Table of Comparison

| Feature | Reactive Dye | Disperse Dye |

|---|---|---|

| Application | Cellulose fibers (cotton, linen) | Synthetic fibers (polyester, nylon) |

| Chemical Bond | Forms covalent bonds with fiber | Physically adheres via dispersion in fiber |

| Colorfastness | High wet and light fastness | High heat and light fastness |

| Water Solubility | Water-soluble | Water-insoluble |

| Environmental Impact | Requires careful effluent management | Contains harmful dispersants, harder to treat |

| Cost | Moderate cost | Relatively higher cost |

| Usage | Used in textile printing and dyeing of cellulose | Used in dyeing of synthetic textiles |

Introduction to Reactive and Disperse Dyes

Reactive dyes form covalent bonds with cellulose fibers, resulting in vibrant, long-lasting colors primarily used for cotton and other plant-based textiles. Disperse dyes, designed for synthetic fibers like polyester and acetate, rely on dispersion in water and penetrate fibers through heat or carriers without chemical bonding. Both dye types offer distinct advantages aligned with fiber composition and desired dyeing processes.

Chemical Structure and Composition

Reactive dyes contain chromophores linked to reactive groups, such as vinyl sulfone or monochlorotriazine, enabling covalent bonding with cellulose fibers in cotton, ensuring high wash fastness. Disperse dyes consist mainly of nonionic, low-water-solubility molecules, often azo or anthraquinone compounds, designed to be finely dispersed in water and absorbed by synthetic fibers like polyester through physical entrapment. Your choice between these dyes depends on fabric type and desired fastness, with the chemical structure directly influencing dye-fiber interaction and durability.

Mechanism of Dyeing Process

Reactive dyes form covalent bonds with cellulose fibers through a chemical reaction involving the dye's reactive groups and the hydroxyl groups of the fiber, ensuring permanent color fixation. Disperse dyes primarily dye synthetic fibers like polyester via a physical process, where dye molecules diffuse into the fiber's amorphous regions under high temperature and pressure. The differing mechanisms result in reactive dyes providing higher wash fastness on natural fibers, while disperse dyes offer better dyeing performance on hydrophobic synthetic substrates.

Suitable Fiber Types

Reactive dyes are primarily suitable for cellulose fibers such as cotton, linen, and viscose, as they form covalent bonds with the fiber molecules, ensuring vibrant and long-lasting colors. Disperse dyes are mainly used for synthetic fibers like polyester, acetate, and nylon, where their small, non-ionic molecules penetrate the hydrophobic fiber structure through a process of dispersion. The choice between reactive and disperse dyes depends largely on the fiber's chemical composition and dyeing mechanism to achieve optimal color fastness and intensity.

Color Fastness Properties

Reactive dyes exhibit excellent color fastness properties on cellulose fibers due to their chemical bonding with the fiber molecules, resulting in high resistance to washing, light, and perspiration. Disperse dyes, primarily used on synthetic fibers like polyester, offer good color fastness to washing and light but generally show lower resistance to rubbing and perspiration compared to reactive dyes. The difference in color fastness between reactive and disperse dyes is largely attributed to their distinct dye-fiber interaction mechanisms, with reactive dyes forming covalent bonds and disperse dyes relying on physical entrapment within fiber polymers.

Environmental Impact and Sustainability

Reactive dyes form covalent bonds with natural fibers, resulting in minimal dye runoff and lower water pollution compared to disperse dyes, which are primarily used on synthetic fibers and often contain harmful chemicals that can persist in the environment. The wastewater from reactive dye processes generally contains fewer toxic substances and exhibits higher biodegradability, enhancing wastewater treatment efficiency. Disperse dyes can release microplastics and aromatic amines, raising sustainability concerns due to their potential bioaccumulation and toxicity in aquatic ecosystems.

Application Methods and Techniques

Reactive dye application primarily involves immersion techniques such as batch dyeing and continuous dyeing on cellulosic fibers, where the dye forms a covalent bond with the fiber, ensuring colorfastness. Disperse dye techniques focus on high-temperature and high-pressure processes like jet, carrier, or hot brand dyeing, optimized for synthetic fibers like polyester to allow dye dispersion into the fiber matrix. Both dye types require precise control of temperature, pH, and time to maximize fixation efficiency and achieve vibrant, durable coloration.

Cost Comparison

Reactive dyes generally cost more than disperse dyes due to their complex chemical structure and the need for precise application conditions to achieve bright, long-lasting colors on natural fibers like cotton. Disperse dyes are typically more affordable and used primarily for synthetic fibers such as polyester, offering a cost-effective solution without compromising colorfastness. Your choice between these dyes depends on the fabric type and budget constraints, with reactive dyes suited for premium cotton textiles and disperse dyes ideal for economical synthetic fabric coloring.

Advantages and Limitations

Reactive dyes offer vibrant colors with excellent wash and light fastness, making them ideal for natural fibers like cotton; their water solubility ensures easy application but requires precise pH and temperature control during fixation. Disperse dyes are best suited for synthetic fabrics such as polyester, providing high colorfastness and resistance to washing and perspiration; however, their hydrophobic nature demands high-temperature dyeing processes and specialized carriers. Reactive dyes can cause environmental concerns due to fixation by-products, while disperse dyes may pose health risks related to their chemical components and dyeing conditions.

Conclusion: Choosing the Right Dye

Selecting the right dye depends on fabric type and desired colorfastness; reactive dyes excel on cellulose fibers like cotton, offering vibrant, long-lasting colors with excellent wash resistance. Disperse dyes are ideal for synthetic fibers such as polyester, providing bright hues with good lightfastness but lower wash durability. Matching the dye to the fiber's chemical nature ensures optimal color performance and fabric lifespan.

Reactive dye vs Disperse dye Infographic

libmatt.com

libmatt.com