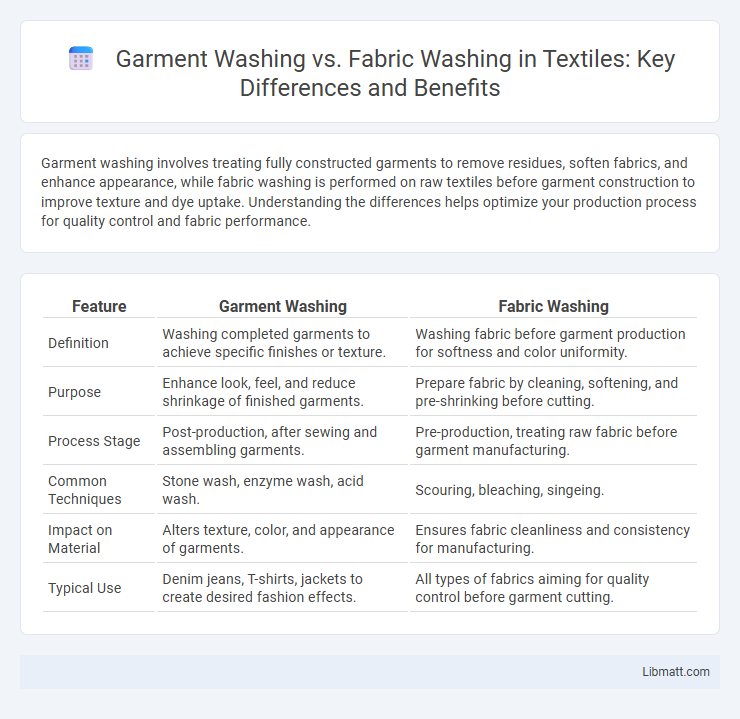

Garment washing involves treating fully constructed garments to remove residues, soften fabrics, and enhance appearance, while fabric washing is performed on raw textiles before garment construction to improve texture and dye uptake. Understanding the differences helps optimize your production process for quality control and fabric performance.

Table of Comparison

| Feature | Garment Washing | Fabric Washing |

|---|---|---|

| Definition | Washing completed garments to achieve specific finishes or texture. | Washing fabric before garment production for softness and color uniformity. |

| Purpose | Enhance look, feel, and reduce shrinkage of finished garments. | Prepare fabric by cleaning, softening, and pre-shrinking before cutting. |

| Process Stage | Post-production, after sewing and assembling garments. | Pre-production, treating raw fabric before garment manufacturing. |

| Common Techniques | Stone wash, enzyme wash, acid wash. | Scouring, bleaching, singeing. |

| Impact on Material | Alters texture, color, and appearance of garments. | Ensures fabric cleanliness and consistency for manufacturing. |

| Typical Use | Denim jeans, T-shirts, jackets to create desired fashion effects. | All types of fabrics aiming for quality control before garment cutting. |

Introduction to Garment Washing and Fabric Washing

Garment washing involves treating finished apparel to enhance softness, color, and texture, using techniques like stone washing or enzyme washing, which improves the overall look and feel of the clothing. Fabric washing, on the other hand, is performed on raw or semi-processed textiles to remove impurities and prepare them for dyeing or printing, ensuring uniformity and quality in production. Understanding the difference between garment washing and fabric washing is essential for optimizing your textile manufacturing process and achieving desired aesthetic and functional qualities.

Key Differences Between Garment Washing and Fabric Washing

Garment washing involves treating fully constructed clothing to achieve specific finishes, colors, or textures, while fabric washing is performed on raw fabric before cutting and sewing, primarily to remove impurities and pre-shrink the material. The key differences lie in their timing within the production process and the effects on the material; garment washing impacts the final product's look and feel, while fabric washing ensures quality and consistency in the fabric itself. Understanding these distinctions helps you choose the appropriate process to enhance your apparel's durability and appearance.

Objectives of Garment Washing

Garment washing aims to enhance the appearance, texture, and comfort of finished clothing by removing impurities, softening fabrics, and achieving desired color effects such as fading or distressing. This process also helps to reduce shrinkage and improve garment fit, ensuring better consumer satisfaction. Techniques like stone washing, enzyme washing, and bleaching are commonly employed to meet these objectives efficiently.

Objectives of Fabric Washing

Fabric washing aims to improve texture, remove impurities, and enhance dye absorption before garment production, ensuring quality and durability. It targets eliminating natural oils, dirt, and chemicals, which optimize fabric hand feel and appearance. Your finished product benefits from consistent color and reduced shrinkage due to these essential pre-treatment processes.

Common Techniques Used in Garment Washing

Common techniques in garment washing include stone washing, enzyme washing, acid washing, and bleach washing, each designed to achieve specific aesthetic effects and fabric textures. Stone washing uses pumice stones to create a worn-in look, while enzyme washing employs cellulase enzymes to soften fabric and enhance color fading. Acid and bleach washing involve chemical treatments to lighten garment colors and create distressed or vintage appearances, contributing to fashion trends and garment customization.

Popular Methods of Fabric Washing

Popular methods of fabric washing include enzyme washing, stone washing, and ozone washing, each enhancing fabric softness and appearance while maintaining durability. Enzyme washing uses cellulase enzymes to remove excess fibers and improve texture, commonly applied to denim fabrics. Stone washing involves pumice stones to create a faded, worn look, whereas ozone washing employs ozone gas to bleach and sanitize without harsh chemicals, offering an eco-friendly alternative.

Impact on Fabric Quality and Appearance

Garment washing affects the overall look and feel of finished clothing, often improving softness, color vibrancy, and reducing shrinkage, whereas fabric washing primarily targets raw textile preparation, enhancing dye absorption and removing impurities to ensure consistent quality. Garment washing techniques like enzyme wash or stone wash can create unique textures and distress effects, directly influencing the final appearance and durability of the product. Fabric washing preserves structural integrity by stabilizing fibers before garment construction, impacting the uniformity and longevity of the fabric in the production process.

Environmental Considerations in Washing Processes

Garment washing typically consumes more water and energy compared to fabric washing due to the larger volume and weight of finished products. Fabric washing can offer better control over chemical usage, reducing harmful effluents and making it a more environmentally friendly option. Your choice between garment and fabric washing impacts water conservation efforts and effluent treatment requirements in the textile industry.

Cost Implications of Garment vs Fabric Washing

Garment washing typically incurs higher costs due to the additional labor, machinery, and handling required to process finished apparel pieces compared to fabric washing, which involves treating raw textiles before garment construction. Fabric washing allows for bulk processing, reducing energy and water consumption per unit, and often results in lower production expenses. However, garment washing adds value through enhanced texture and appearance, justifying the elevated investment in premium apparel manufacturing.

Choosing the Right Washing Process for Apparel Manufacturing

Choosing the right washing process for apparel manufacturing involves evaluating garment washing and fabric washing based on desired texture, durability, and appearance. Garment washing allows for specific effects such as stone washing or enzyme washing directly on finished apparel, enhancing softness and unique looks. Fabric washing, performed before garment construction, ensures consistent fabric quality and dye fixation, making it ideal for uniformity and improved fabric strength in your production line.

Garment washing vs Fabric washing Infographic

libmatt.com

libmatt.com