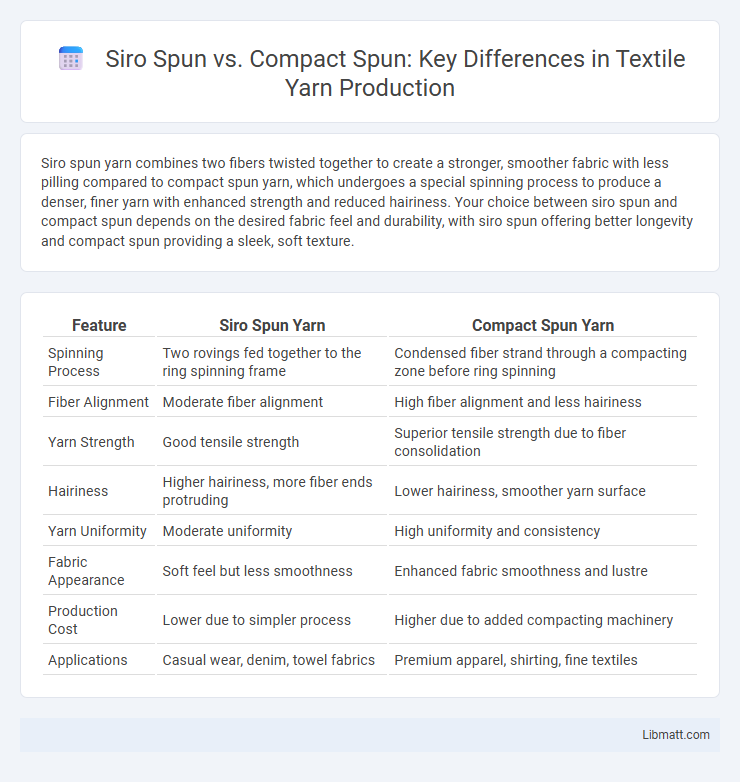

Siro spun yarn combines two fibers twisted together to create a stronger, smoother fabric with less pilling compared to compact spun yarn, which undergoes a special spinning process to produce a denser, finer yarn with enhanced strength and reduced hairiness. Your choice between siro spun and compact spun depends on the desired fabric feel and durability, with siro spun offering better longevity and compact spun providing a sleek, soft texture.

Table of Comparison

| Feature | Siro Spun Yarn | Compact Spun Yarn |

|---|---|---|

| Spinning Process | Two rovings fed together to the ring spinning frame | Condensed fiber strand through a compacting zone before ring spinning |

| Fiber Alignment | Moderate fiber alignment | High fiber alignment and less hairiness |

| Yarn Strength | Good tensile strength | Superior tensile strength due to fiber consolidation |

| Hairiness | Higher hairiness, more fiber ends protruding | Lower hairiness, smoother yarn surface |

| Yarn Uniformity | Moderate uniformity | High uniformity and consistency |

| Fabric Appearance | Soft feel but less smoothness | Enhanced fabric smoothness and lustre |

| Production Cost | Lower due to simpler process | Higher due to added compacting machinery |

| Applications | Casual wear, denim, towel fabrics | Premium apparel, shirting, fine textiles |

Introduction to Siro Spun and Compact Spun Yarns

Siro spun yarns are produced by simultaneously feeding two rovings into the drafting system, resulting in a yarn with improved strength, reduced hairiness, and consistent evenness compared to conventional ring-spun yarns. Compact spun yarns use a compacting zone after drafting to condense fiber strands, enhancing fiber alignment and reducing yarn hairiness, leading to superior tensile strength and fabric smoothness. Both technologies optimize yarn quality for diverse textile applications, with Siro spun focusing on balanced fiber integration and Compact spun emphasizing fiber compaction.

Historical Development of Spinning Technologies

Siro spun yarn emerged in the mid-20th century as an innovation combining two rovings simultaneously to produce a stronger, finer yarn with reduced hairiness compared to traditional compact spun yarn developed earlier in the 1950s. Compact spinning technology evolved from ring spinning with advancements in fiber drafting and condensed fiber formation, significantly improving yarn strength and fabric quality by minimizing fiber fly and hairiness. Both technologies represent milestones in spinning history, with Siro spun focusing on efficiency and balanced yarn structure, while compact spinning emphasizes enhanced fiber alignment and compactness for high-performance textiles.

Production Process: Siro Spun vs Compact Spun

Siro Spun yarn is produced using two parallel rovings fed simultaneously into the spinning zone, which reduces hairiness and enhances strength by twisting the fibers together from both sides. Compact Spun yarn involves an additional fiber condensing step after carding, where fibers are aligned and compressed before twisting, resulting in a denser, smoother yarn with fewer protruding fibers. The main distinction lies in Siro Spun's dual-roving feeding process versus Compact Spun's fiber condensing technology, both aimed at improving yarn quality through different production mechanisms.

Fiber Alignment and Yarn Structure Differences

Siro spun yarn features better fiber alignment due to its simultaneous dual-roving twisting process, resulting in a more compact and stronger yarn structure compared to traditional compact spun yarn. Compact spun yarn achieves fiber consolidation through pneumatic drafting, which reduces hairiness but offers less fiber parallelism than Siro spun. The enhanced fiber alignment in Siro spun yarn leads to improved tensile strength and uniformity, while compact spun yarn excels in smoothness and reduced pilling.

Physical Properties of Siro and Compact Spun Yarns

Siro spun yarns exhibit higher tensile strength and improved uniformity due to the twin-roller spinning process, which reduces fiber unevenness and hairiness. Compact spun yarns show enhanced fiber alignment and density, resulting in greater abrasion resistance and smoother yarn surface compared to conventional ring-spun yarns. Both yarn types provide superior physical properties, with Siro spun favoring reduced pilling and Compact spun enhancing fabric softness and durability.

Comparative Analysis: Strength and Hairiness

Siro spun yarn exhibits higher strength and reduced hairiness compared to compact spun yarn due to its unique twin-filament spinning process that tightly twists fibers together, resulting in enhanced durability and smoother surface. Compact spun yarn, while also offering improved strength over conventional ring-spun yarn, tends to have slightly more hairiness than Siro spun because of its fiber parallelization method that consolidates but does not fully eliminate fiber protrusion. Choosing Siro spun yarn for your textiles can lead to products with superior tensile strength and a cleaner appearance, ideal for high-quality fabric applications.

Applications in Textile Industry

Siro spun yarn, created by feeding two rovings simultaneously into the spinning system, offers enhanced strength and uniformity, making it ideal for high-quality woven fabrics and knitting applications in the textile industry. Compact spun yarns, produced through a process that condenses fibers before twisting, provide superior fiber alignment and reduced hairiness, resulting in better fabric smoothness and durability, preferred for premium shirting, denim, and technical textiles. Both yarn types improve fabric performance, but Siro spun is favored for softness and elasticity, while Compact spun excels in abrasion resistance and fine detailing.

Cost-Efficiency and Manufacturing Considerations

Siro spun yarn offers cost-efficiency through reduced raw material waste and faster production speeds compared to compact spun yarn, which demands higher investment in advanced machinery due to its complex fiber alignment process. Manufacturing considerations for Siro spun emphasize simpler equipment setup and energy savings, while compact spun requires precision technology to achieve superior yarn strength and a smoother surface. Despite higher initial costs, compact spun may yield long-term savings in fabric quality and durability, making it suitable for premium textile applications.

Sustainability and Environmental Impact

Siro spun yarn uses a twin-rod spinning process that reduces fiber waste by improving fiber alignment, resulting in less material consumption and lower energy use compared to traditional Compact spun yarn production. Compact spun yarn, while offering higher yarn strength and reduced hairiness, typically requires more intensive machinery and higher energy input, contributing to a larger environmental footprint. Selecting Siro spun yarn supports sustainable textile manufacturing by minimizing raw material waste and lowering carbon emissions throughout the production cycle.

Future Trends in Yarn Spinning Technologies

Siro spun and compact spun yarns represent critical advancements in yarn spinning, with future trends emphasizing enhanced fiber alignment and reduced hairiness for superior fabric quality. Emerging technologies aim to integrate AI-driven monitoring systems and sustainable practices, improving efficiency and minimizing environmental impact. Innovations in these spinning methods will likely lead to greater consistency, strength, and softness, meeting the growing demand for high-performance textiles.

Siro spun vs Compact spun Infographic

libmatt.com

libmatt.com