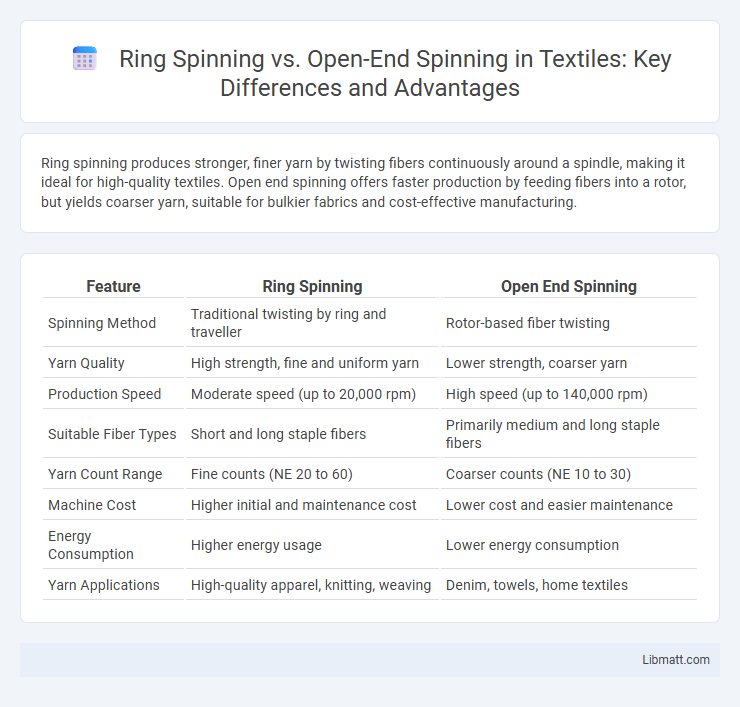

Ring spinning produces stronger, finer yarn by twisting fibers continuously around a spindle, making it ideal for high-quality textiles. Open end spinning offers faster production by feeding fibers into a rotor, but yields coarser yarn, suitable for bulkier fabrics and cost-effective manufacturing.

Table of Comparison

| Feature | Ring Spinning | Open End Spinning |

|---|---|---|

| Spinning Method | Traditional twisting by ring and traveller | Rotor-based fiber twisting |

| Yarn Quality | High strength, fine and uniform yarn | Lower strength, coarser yarn |

| Production Speed | Moderate speed (up to 20,000 rpm) | High speed (up to 140,000 rpm) |

| Suitable Fiber Types | Short and long staple fibers | Primarily medium and long staple fibers |

| Yarn Count Range | Fine counts (NE 20 to 60) | Coarser counts (NE 10 to 30) |

| Machine Cost | Higher initial and maintenance cost | Lower cost and easier maintenance |

| Energy Consumption | Higher energy usage | Lower energy consumption |

| Yarn Applications | High-quality apparel, knitting, weaving | Denim, towels, home textiles |

Introduction to Spinning Methods

Ring spinning produces yarn by continuously drawing out fibers and twisting them around a spindle, resulting in strong, fine, and smooth yarn suitable for high-quality textiles. Open end spinning, also known as rotor spinning, automates fiber collection and yarn formation by feeding slivers into a rotor where fibers are twisted together, enabling faster production rates and coarser yarns ideal for mass-market fabrics. These spinning methods differ in speed, yarn strength, texture, and fiber compatibility, influencing their applications in textile manufacturing.

Overview of Ring Spinning

Ring spinning remains the dominant yarn production technique known for producing fine, strong, and uniform yarns ideal for high-quality textiles. This method involves twisting drawn fibers through a rotating spindle and ring traveler, resulting in superior yarn strength compared to open end spinning. Ring spinning excels in producing a wide range of yarn counts, especially for fine and medium counts, making it preferable for premium fabrics and detailed textile applications.

Overview of Open End Spinning

Open End Spinning is a highly efficient textile production process that employs a rotor to twist and spin fibers into yarn without using a spindle, allowing for faster manufacturing speeds compared to Ring Spinning. This technique is best suited for producing coarse yarns with medium to low strength, commonly used in products like denim, towels, and upholstery fabrics. If you're seeking a cost-effective solution for high-volume yarn production, Open End Spinning offers significant advantages in terms of speed and reduced labor requirements.

Key Differences Between Ring and Open End Spinning

Ring spinning produces finer, stronger yarns with better uniformity and is ideal for high-quality textiles, while open end spinning offers faster production speeds and lower costs but results in coarser yarns with less strength. Ring spinning involves continuous twisting of fibers on a spindle, creating a compact yarn structure, whereas open end spinning uses a rotor to collect and twist fibers rapidly without continuous twisting. Your choice depends on the desired fabric quality, production efficiency, and cost considerations.

Yarn Quality: Ring Spinning vs Open End Spinning

Ring spinning produces yarn with superior strength, finer count, and higher uniformity due to its continuous and controlled twisting process, making it ideal for premium textile applications. Open end spinning, while faster and more cost-effective, generates coarser, less uniform yarn with lower tensile strength, limiting its use to bulkier or lower-grade fabrics. Your choice between these methods should prioritize yarn quality requirements for the intended fabric performance and end-use.

Production Speed and Efficiency Comparison

Ring spinning offers high yarn quality but operates at slower speeds, typically around 15,000 to 20,000 revolutions per minute (RPM), resulting in lower production rates. Open end spinning achieves significantly higher production speeds, often exceeding 30,000 RPM, enhancing efficiency and output volume. The efficiency advantage of open end spinning lies in its ability to produce yarn continuously without the need for a spindle, reducing labor and maintenance costs.

Cost Analysis: Investment and Operation

Ring spinning requires higher initial investment due to complex machinery and skilled labor, resulting in increased maintenance and operational costs. Open end spinning offers lower capital expenditure and faster production rates, reducing overall operational expenses and making it cost-effective for high-volume output. Your choice depends on the balance between investment capacity and desired production efficiency.

Applications and End Uses of Each Method

Ring spinning produces high-quality yarns ideal for fine textiles such as dress shirts, hosiery, and premium denim, offering superior strength and smoothness. Open end spinning is suited for coarser yarns used in products like towels, blankets, and upholstery fabrics due to its higher production speed and cost efficiency. Your choice between these methods depends on the desired fabric texture, durability, and application requirements.

Environmental Impact and Sustainability

Ring spinning produces finer, stronger yarn with higher energy consumption and water usage, contributing to a larger environmental footprint. Open end spinning uses less water and energy, resulting in reduced carbon emissions and better sustainability performance. Choosing open end spinning can help your textile production align with eco-friendly and sustainable practices.

Choosing the Right Spinning Method for Your Needs

Ring spinning offers superior yarn strength and finer quality, making it ideal for high-end textiles requiring durability and softness. Open end spinning provides faster production rates and cost efficiency, suitable for coarse yarns and bulk manufacturing. Selecting the right method depends on balancing desired yarn properties, production speed, and budget constraints for optimized textile output.

Ring spinning vs Open end spinning Infographic

libmatt.com

libmatt.com