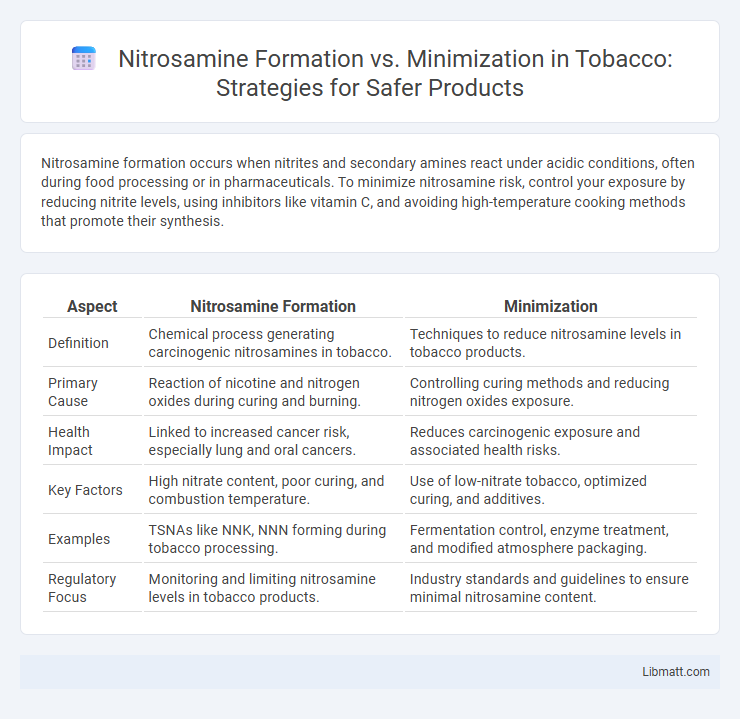

Nitrosamine formation occurs when nitrites and secondary amines react under acidic conditions, often during food processing or in pharmaceuticals. To minimize nitrosamine risk, control your exposure by reducing nitrite levels, using inhibitors like vitamin C, and avoiding high-temperature cooking methods that promote their synthesis.

Table of Comparison

| Aspect | Nitrosamine Formation | Minimization |

|---|---|---|

| Definition | Chemical process generating carcinogenic nitrosamines in tobacco. | Techniques to reduce nitrosamine levels in tobacco products. |

| Primary Cause | Reaction of nicotine and nitrogen oxides during curing and burning. | Controlling curing methods and reducing nitrogen oxides exposure. |

| Health Impact | Linked to increased cancer risk, especially lung and oral cancers. | Reduces carcinogenic exposure and associated health risks. |

| Key Factors | High nitrate content, poor curing, and combustion temperature. | Use of low-nitrate tobacco, optimized curing, and additives. |

| Examples | TSNAs like NNK, NNN forming during tobacco processing. | Fermentation control, enzyme treatment, and modified atmosphere packaging. |

| Regulatory Focus | Monitoring and limiting nitrosamine levels in tobacco products. | Industry standards and guidelines to ensure minimal nitrosamine content. |

Understanding Nitrosamine Formation

Nitrosamine formation occurs primarily during the reaction between secondary or tertiary amines and nitrosating agents, such as nitrites, under acidic conditions commonly found in the stomach or certain industrial processes. Factors influencing nitrosamine formation include the availability of nitrosating agents, pH levels, temperature, and presence of catalysts like metals. Understanding the chemical pathways and conditions leading to nitrosamine synthesis is essential for developing effective strategies to minimize their formation in food products, pharmaceuticals, and environmental contexts.

Key Factors Influencing Nitrosamine Generation

Nitrosamine formation primarily occurs through the reaction of secondary amines with nitrosating agents under acidic conditions, often influenced by temperature, pH, and the presence of nitrites or nitrates. Key factors influencing nitrosamine generation include the concentration of nitrosating precursors, availability of secondary or tertiary amines, and environmental conditions such as heat and acidity that accelerate the reaction. Your approach to minimization should target controlling these variables by reducing nitrite content, adjusting pH levels, and limiting exposure to high temperatures to effectively inhibit nitrosamine formation.

Sources of Nitrosamine Contamination

Nitrosamine contamination primarily originates from food processing, pharmaceuticals, and tobacco products where nitrites react with secondary amines under acidic conditions. Contaminated water and certain cosmetic formulations also contribute to nitrosamine presence, posing health risks due to their carcinogenic potential. You can minimize nitrosamine formation by controlling nitrite levels, adjusting pH, and using antioxidants during manufacturing and storage.

Health Risks Associated with Nitrosamines

Nitrosamines are potent carcinogens formed primarily through the reaction of nitrites and secondary amines, posing significant health risks such as increased chances of developing cancers, including gastric and esophageal cancer. Minimizing nitrosamine formation involves controlling nitrite levels in food processing, avoiding high-temperature cooking methods like frying or grilling, and using antioxidants that inhibit nitrosamine synthesis. Your awareness of these factors can reduce exposure and protect against the harmful effects associated with nitrosamine intake.

Analytical Methods for Detecting Nitrosamines

Analytical methods for detecting nitrosamines primarily include gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-tandem mass spectrometry (LC-MS/MS), which provide high sensitivity and specificity for trace-level analysis. Solid-phase extraction (SPE) is often employed for sample pre-concentration and cleanup to improve detection limits in complex matrices such as pharmaceuticals and food products. Advances in real-time monitoring techniques and ultra-high-performance liquid chromatography (UHPLC) have further enhanced the accuracy and speed of nitrosamine quantification essential for regulatory compliance and risk assessment.

Regulatory Guidelines for Nitrosamine Levels

Regulatory guidelines for nitrosamine levels primarily aim to limit the presence of these carcinogenic compounds in pharmaceuticals, food, and water, ensuring consumer safety. Agencies like the FDA and EMA have established strict permissible limits and testing protocols to detect and control nitrosamine formation during manufacturing and storage. You must adhere to these regulations by implementing validated analytical methods and optimizing production processes to minimize nitrosamine contamination effectively.

Strategies for Nitrosamine Minimization

Strategies for nitrosamine minimization focus on controlling precursor chemicals such as secondary amines and nitrosating agents by implementing strict raw material selection and optimizing manufacturing conditions. Monitoring pH levels, temperature, and storage conditions effectively reduces nitrosamine formation during production and shelf life. You can also adopt advanced analytical techniques for early detection to ensure compliance with regulatory limits and enhance product safety.

Process Optimization to Reduce Nitrosamines

Process optimization to reduce nitrosamines involves controlling reaction conditions such as pH, temperature, and reagent concentrations to inhibit nitrosation reactions. Implementing catalytic inhibitors and adjusting solvent systems can significantly decrease nitrosamine formation during chemical synthesis. Employing advanced analytical monitoring enables real-time adjustments, ensuring minimal nitrosamine contamination in pharmaceutical and industrial manufacturing.

Case Studies in Nitrosamine Control

Case studies in nitrosamine control highlight successful strategies in reducing nitrosamine formation through optimized reaction conditions and the use of specific inhibitors. You can minimize nitrosamine risks by controlling precursor levels, adjusting pH, and employing advanced analytical monitoring techniques. Data from pharmaceutical and water treatment industries demonstrate practical approaches to effectively manage nitrosamine contamination.

Future Directions in Nitrosamine Research

Future directions in nitrosamine research emphasize the development of advanced analytical techniques for more accurate detection and quantification of nitrosamines in pharmaceuticals and food products. Innovations in synthetic chemistry aim to minimize nitrosamine formation by designing safer drug compounds and optimizing manufacturing processes. Research also explores novel inhibitors and scavengers that can effectively prevent nitrosamine generation during production and storage.

Nitrosamine formation vs minimization Infographic

libmatt.com

libmatt.com