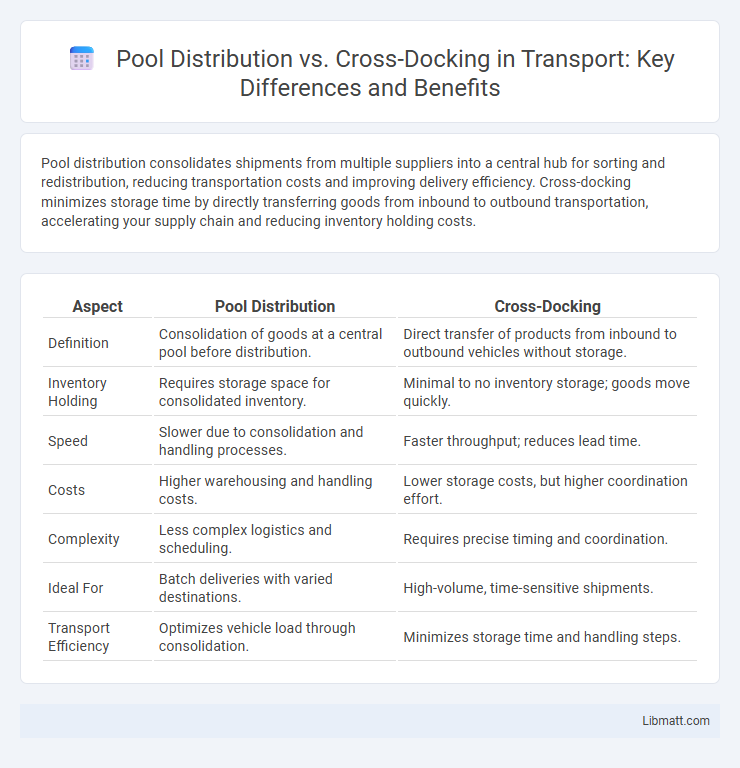

Pool distribution consolidates shipments from multiple suppliers into a central hub for sorting and redistribution, reducing transportation costs and improving delivery efficiency. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, accelerating your supply chain and reducing inventory holding costs.

Table of Comparison

| Aspect | Pool Distribution | Cross-Docking |

|---|---|---|

| Definition | Consolidation of goods at a central pool before distribution. | Direct transfer of products from inbound to outbound vehicles without storage. |

| Inventory Holding | Requires storage space for consolidated inventory. | Minimal to no inventory storage; goods move quickly. |

| Speed | Slower due to consolidation and handling processes. | Faster throughput; reduces lead time. |

| Costs | Higher warehousing and handling costs. | Lower storage costs, but higher coordination effort. |

| Complexity | Less complex logistics and scheduling. | Requires precise timing and coordination. |

| Ideal For | Batch deliveries with varied destinations. | High-volume, time-sensitive shipments. |

| Transport Efficiency | Optimizes vehicle load through consolidation. | Minimizes storage time and handling steps. |

Understanding Pool Distribution and Cross-Docking

Pool distribution consolidates shipments from multiple suppliers at a central location to optimize transportation routes and reduce costs, enhancing supply chain efficiency. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, speeding up delivery and decreasing inventory holding expenses. Both methods improve logistics but serve different operational needs: pool distribution focuses on shipment consolidation, while cross-docking emphasizes rapid throughput.

Key Differences Between Pool Distribution and Cross-Docking

Pool distribution consolidates shipments from multiple suppliers to optimize delivery routes and reduce costs by distributing products through a shared facility, while cross-docking involves immediate transfer of goods from inbound to outbound vehicles with minimal storage time. Your supply chain benefits from pool distribution through inventory aggregation and reduced handling, whereas cross-docking excels in minimizing storage and speeding up delivery times. These key differences impact operational efficiency, inventory management, and transportation expenses.

How Pool Distribution Works

Pool distribution consolidates shipments from multiple suppliers at a central hub, where goods are sorted and consolidated before final delivery to various destinations. This method reduces transportation costs and improves delivery efficiency by optimizing load capacity and minimizing direct trips. Pool distribution is ideal for companies seeking to streamline logistics through shared transportation resources while maintaining timely delivery schedules.

The Cross-Docking Process Explained

Cross-docking is a logistics strategy where incoming goods are directly transferred from inbound to outbound transportation with minimal or no storage time, facilitating faster delivery and reduced inventory costs. This process involves staging areas and synchronized scheduling to ensure products move efficiently through docking bays, bypassing warehouse storage. Compared to traditional pool distribution, cross-docking enhances supply chain responsiveness by reducing handling times and streamlining the flow of goods.

Advantages of Pool Distribution

Pool distribution minimizes transportation costs by consolidating shipments from multiple suppliers into a single delivery route. This method enhances delivery efficiency and reduces environmental impact through fewer trips and optimized load capacities. It also improves inventory management by centralizing goods before final distribution, allowing for better demand forecasting and reduced stock levels.

Benefits of Cross-Docking for Supply Chains

Cross-docking reduces inventory holding costs by minimizing storage time and accelerating product flow from suppliers to customers. This method enhances supply chain efficiency through faster order fulfillment and lower transportation expenses by consolidating shipments. Real-time inventory management and reduced handling errors further improve overall operational responsiveness and customer satisfaction.

Challenges and Limitations of Pool Distribution

Pool distribution faces challenges such as complex coordination among multiple suppliers, leading to potential delays and increased handling costs. Limited flexibility in shipment schedules can affect Your ability to respond swiftly to market demands, while dependency on shared infrastructure may result in less control over inventory accuracy. Inefficiencies in consolidating diverse products can reduce overall distribution effectiveness compared to cross-docking systems.

Drawbacks of Cross-Docking Operations

Cross-docking operations often face challenges such as high dependency on precise timing and coordination, which can lead to delays and increased operational complexity. Limited storage capabilities in cross-docking require efficient handling of goods, making it vulnerable to disruptions in the supply chain. Your business may experience higher risks of inventory mismanagement and increased labor costs due to the intense focus on rapid sorting and distribution.

Choosing the Right Strategy: Pool Distribution vs Cross-Docking

Pool distribution consolidates shipments from multiple suppliers to optimize transportation costs and improve delivery efficiency by reducing last-mile expenses. Cross-docking minimizes inventory holding by directly transferring goods from inbound to outbound transportation, enabling faster order fulfillment and lower storage costs. Selecting between pool distribution and cross-docking hinges on factors like order volume, delivery speed requirements, inventory management capabilities, and transportation cost trade-offs.

Future Trends in Distribution and Cross-Docking Logistics

Future trends in pool distribution and cross-docking logistics emphasize increased automation and real-time data integration to enhance efficiency and reduce delivery times. Advanced technologies like AI-driven route optimization and IoT-enabled inventory tracking are transforming how goods move from suppliers to end consumers. Your logistics strategy can gain competitive advantage by adopting these innovations to streamline distribution networks and improve supply chain responsiveness.

pool distribution vs cross-docking Infographic

libmatt.com

libmatt.com