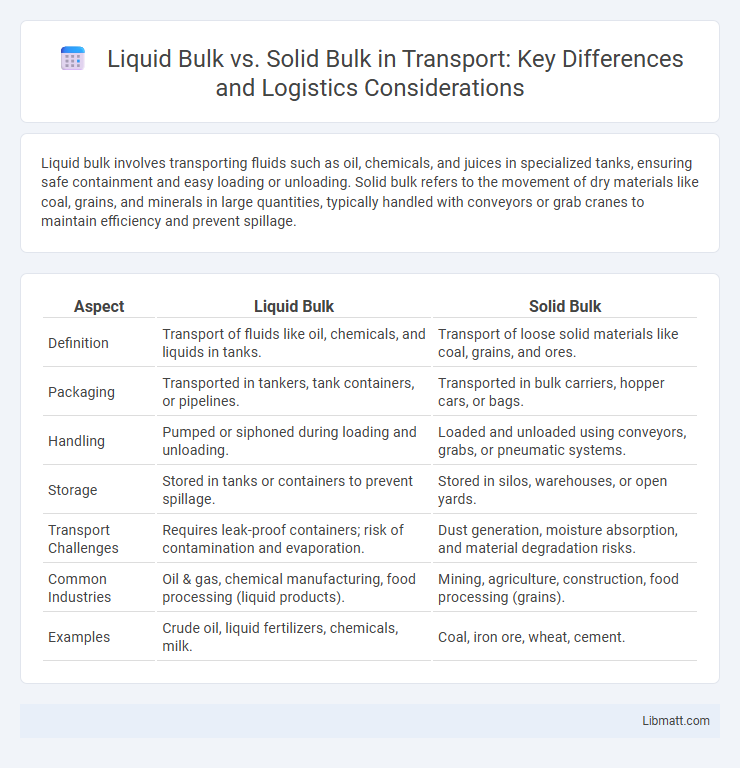

Liquid bulk involves transporting fluids such as oil, chemicals, and juices in specialized tanks, ensuring safe containment and easy loading or unloading. Solid bulk refers to the movement of dry materials like coal, grains, and minerals in large quantities, typically handled with conveyors or grab cranes to maintain efficiency and prevent spillage.

Table of Comparison

| Aspect | Liquid Bulk | Solid Bulk |

|---|---|---|

| Definition | Transport of fluids like oil, chemicals, and liquids in tanks. | Transport of loose solid materials like coal, grains, and ores. |

| Packaging | Transported in tankers, tank containers, or pipelines. | Transported in bulk carriers, hopper cars, or bags. |

| Handling | Pumped or siphoned during loading and unloading. | Loaded and unloaded using conveyors, grabs, or pneumatic systems. |

| Storage | Stored in tanks or containers to prevent spillage. | Stored in silos, warehouses, or open yards. |

| Transport Challenges | Requires leak-proof containers; risk of contamination and evaporation. | Dust generation, moisture absorption, and material degradation risks. |

| Common Industries | Oil & gas, chemical manufacturing, food processing (liquid products). | Mining, agriculture, construction, food processing (grains). |

| Examples | Crude oil, liquid fertilizers, chemicals, milk. | Coal, iron ore, wheat, cement. |

Introduction to Liquid Bulk and Solid Bulk

Liquid bulk refers to any cargo transported in a liquid state, such as crude oil, chemicals, and liquefied natural gas, requiring specialized tanks and handling equipment for safe storage and transfer. Solid bulk consists of unpackaged solid materials like coal, grain, and minerals, moved in large quantities using conveyors, hoppers, or grabs, typically stored in silos or open yards. Understanding the differences in handling, storage, and transportation methods for liquid and solid bulk ensures efficient logistics tailored to the specific properties of your cargo.

Key Differences Between Liquid Bulk and Solid Bulk

Liquid bulk consists of fluids such as crude oil, chemicals, and liquefied gases transported in tankers, while solid bulk includes granular materials like coal, grain, and minerals shipped in bulk carriers. Liquid bulk requires specialized containment systems like tanks and pipelines to prevent spillage and contamination, whereas solid bulk depends on cargo holds and conveyor systems for loading and unloading. Handling liquid bulk demands strict monitoring of temperature and pressure, contrasting with the focus on moisture control and dust suppression in solid bulk transportation.

Types of Liquid Bulk Cargo

Liquid bulk cargo primarily consists of commodities such as crude oil, refined petroleum products, chemicals, vegetable oils, and liquefied natural gas (LNG). These liquids require specialized handling and storage equipment like tankers and insulated tanks to prevent contamination and maintain temperature stability. Your choice between liquid bulk and solid bulk depends on the type, viscosity, and chemical properties of the cargo you need to transport.

Types of Solid Bulk Cargo

Solid bulk cargo includes a wide range of materials such as coal, iron ore, grains, cement, and minerals that are transported in loose form without packaging. These cargoes require specialized handling equipment like grabs, conveyor belts, and hoppers to ensure efficient loading and unloading. Understanding the types of solid bulk cargo helps you optimize storage and transportation logistics for industries like agriculture, construction, and mining.

Storage and Handling Requirements

Liquid bulk cargo requires specialized storage tanks constructed from materials resistant to chemical corrosion and equipped with safety systems such as pressure relief valves and leak detection sensors, ensuring secure containment and minimizing environmental risks. Solid bulk cargo demands robust, moisture-resistant storage facilities like silos and warehouses with proper ventilation to prevent clumping, dust generation, and spontaneous combustion hazards during prolonged storage and handling. Handling liquid bulk involves pumps, pipelines, and sealed connections to prevent spills and contamination, whereas solid bulk relies on conveyors, loaders, and grab buckets designed for efficient transfer and reduced particle loss.

Transportation Methods for Bulk Cargo

Liquid bulk cargo primarily relies on tanker ships and tank trucks designed for efficient transportation of fluids such as crude oil, chemicals, and liquid food products, employing specialized containment systems to prevent leaks and contamination. Solid bulk cargo is mainly transported via bulk carriers, railcars, and conveyor belts, accommodating commodities like coal, grain, and minerals with robust handling equipment to manage heavy and abrasive materials. Both transportation methods demand tailored infrastructure and safety protocols to optimize loading, unloading, and storage during transit.

Safety Measures in Bulk Cargo Management

Safety measures in liquid bulk cargo management prioritize preventing leaks, spills, and chemical reactions through specialized containment systems and continuous monitoring of pressure and temperature. Solid bulk cargo requires rigorous control of dust emissions, proper securing to avoid shifting during transit, and moisture management to prevent cargo degradation or hazards such as spontaneous combustion. Your compliance with international safety standards and the use of advanced detection technologies are critical to minimizing risks in both cargo types.

Environmental Impact: Liquid vs Solid Bulk

Liquid bulk cargoes, such as crude oil and chemicals, pose significant environmental risks due to potential spills that can contaminate water sources and marine ecosystems, leading to long-lasting damage. Solid bulk materials, including coal and minerals, primarily impact air quality through dust emissions and can affect soil and water through runoff during transportation. Your choice between liquid and solid bulk shipping should consider these environmental implications to minimize ecological harm and comply with stricter regulations.

Common Challenges in Bulk Cargo Logistics

Handling liquid bulk and solid bulk cargo presents unique challenges in bulk cargo logistics, such as the risk of spillage and contamination for liquids and difficulties in unloading and dust control for solids. Proper storage facilities and specialized equipment are essential to maintain product integrity and prevent environmental hazards. You must ensure rigorous safety protocols and efficient handling processes to minimize delays and loss during transportation.

Choosing the Right Bulk Cargo Solution

Selecting the appropriate bulk cargo solution depends on the nature and handling requirements of the material transported. Liquid bulk cargo, including petroleum, chemicals, and edible oils, necessitates specialized tank containers or vessels designed to prevent contamination and spillage. Solid bulk cargo, such as coal, grain, and minerals, requires different containment methods like bulk carriers or hopper cars to ensure efficient loading, unloading, and protection from environmental exposure.

liquid bulk vs solid bulk Infographic

libmatt.com

libmatt.com