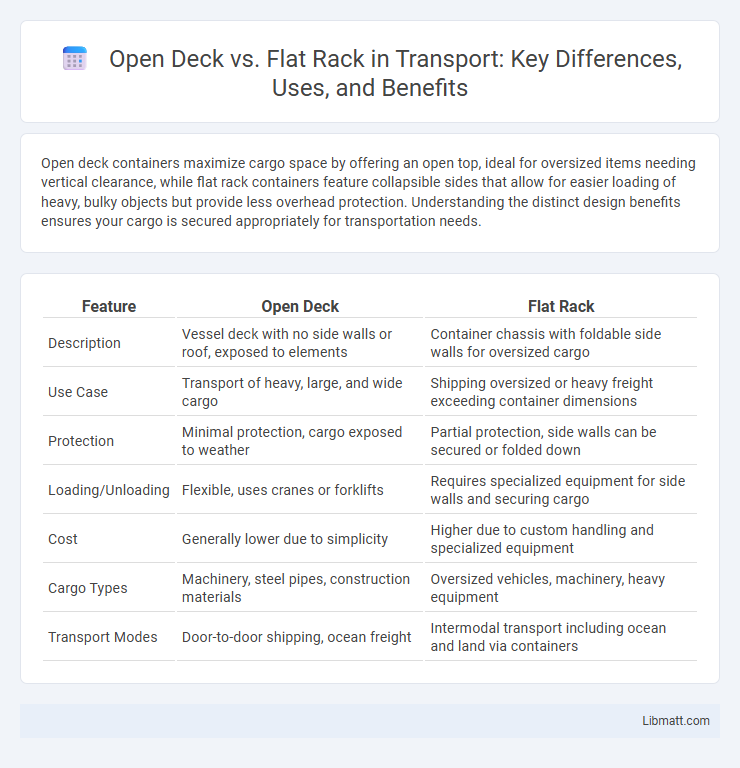

Open deck containers maximize cargo space by offering an open top, ideal for oversized items needing vertical clearance, while flat rack containers feature collapsible sides that allow for easier loading of heavy, bulky objects but provide less overhead protection. Understanding the distinct design benefits ensures your cargo is secured appropriately for transportation needs.

Table of Comparison

| Feature | Open Deck | Flat Rack |

|---|---|---|

| Description | Vessel deck with no side walls or roof, exposed to elements | Container chassis with foldable side walls for oversized cargo |

| Use Case | Transport of heavy, large, and wide cargo | Shipping oversized or heavy freight exceeding container dimensions |

| Protection | Minimal protection, cargo exposed to weather | Partial protection, side walls can be secured or folded down |

| Loading/Unloading | Flexible, uses cranes or forklifts | Requires specialized equipment for side walls and securing cargo |

| Cost | Generally lower due to simplicity | Higher due to custom handling and specialized equipment |

| Cargo Types | Machinery, steel pipes, construction materials | Oversized vehicles, machinery, heavy equipment |

| Transport Modes | Door-to-door shipping, ocean freight | Intermodal transport including ocean and land via containers |

Introduction to Open Deck and Flat Rack Containers

Open deck containers feature an open-top structure, allowing easy loading of heavy and oversized cargo like machinery and construction materials. Flat rack containers have collapsible sides designed for transporting large, awkwardly shaped items such as vehicles and industrial equipment. Both container types optimize shipping efficiency by accommodating goods that do not fit standard container dimensions.

Key Differences Between Open Deck and Flat Rack

Open deck containers provide a flat surface with no side walls or roof, ideal for oversized cargo that cannot fit into standard containers. Flat rack containers feature collapsible sides, offering structural support for heavy, irregularly shaped items while enabling easy loading and unloading from the top or sides. The primary difference lies in the presence of collapsible sides on flat racks, enhancing cargo security compared to the completely open structure of open deck containers.

Structural Features of Open Deck Containers

Open deck containers feature a robust steel frame with removable or collapsible side walls, allowing for easy loading and unloading of oversized cargo that cannot fit into standard containers. The open design supports heavy and irregularly shaped items by providing maximum flexibility and accessible space without side constraints. Your choice between an open deck and a flat rack depends on the need for structural support and protection, as open deck containers offer more rigidity due to their enclosed deck and frame construction.

Structural Features of Flat Rack Containers

Flat rack containers feature reinforced corner posts and strong steel frames designed to support heavy and oversized cargo that exceeds the standard container dimensions. Their collapsible side walls and open top enable easy loading and unloading of awkwardly shaped goods, unlike open deck containers which lack structural side supports. These structural enhancements make flat racks ideal for transporting machinery, vehicles, and construction materials requiring secure, adaptable containment.

Common Uses for Open Deck Containers

Open deck containers are primarily used for transporting oversized machinery, heavy equipment, and construction materials that exceed standard container dimensions. Their removable sides facilitate easy loading and unloading of bulky cargo, making them ideal for industrial and manufacturing sectors. These containers offer versatility for carrying items with irregular shapes that cannot fit into regular enclosed containers.

Common Applications of Flat Rack Containers

Flat rack containers are ideal for transporting heavy machinery, vehicles, and oversized cargo that cannot fit into standard containers due to height or width constraints. Common applications include shipping construction equipment, large pipes, and industrial materials that require open sides for loading with cranes or forklifts. Your choice of flat rack containers facilitates efficient handling of bulky goods in industries like manufacturing, construction, and agriculture.

Loading and Securing Cargo: Open Deck vs Flat Rack

Open deck containers allow easy loading of oversized or awkward cargo from the top or sides, but require careful securing with straps and tarps to protect against weather and shifting. Flat rack containers feature collapsible sides and are designed for heavy or bulky items, providing robust support and easier lashing points for securing your cargo firmly in place during transit. Choosing between them depends on the cargo's size, weight, and the level of protection needed for safe transportation.

Cost Considerations and Pricing Comparison

Open deck containers typically offer lower shipping costs compared to flat racks due to simpler construction and multipurpose use in general freight. Flat racks are priced higher because of reinforced frames designed for heavy or irregularly shaped cargo needing extra support. Your choice affects budget efficiency, with open decks being cost-effective for lighter loads and flat racks justifying their premium for bulky or heavy items requiring secure handling.

Advantages and Disadvantages of Each Option

Open deck containers offer easy loading and unloading of oversized cargo but provide limited protection from weather and theft. Flat rack containers excel at transporting heavy or bulky items with flexible side panels but require more secure strapping and careful handling to prevent damage. Your choice depends on the balance between cargo protection and ease of access during shipping.

Choosing the Right Solution: Factors to Consider

Selecting between open deck and flat rack shipping containers depends on cargo size, weight, and protection needs. Open decks are ideal for heavy, oversized machinery that withstands weather, while flat racks suit bulky loads requiring partial enclosure or easy loading. Consider factors like cargo dimensions, loading methods, transit conditions, and budget constraints to ensure optimal transport efficiency and safety.

open deck vs flat rack Infographic

libmatt.com

libmatt.com