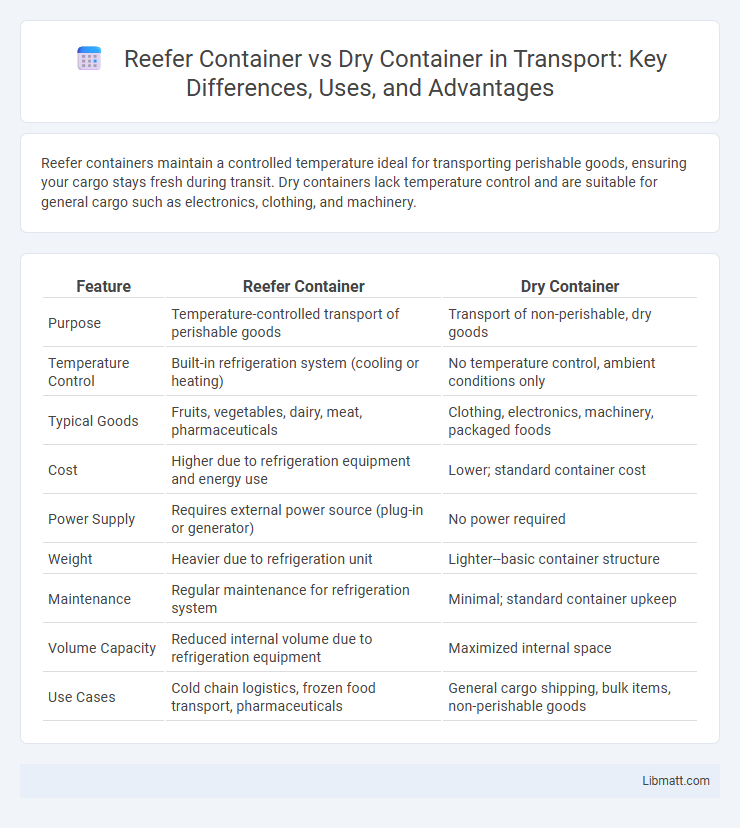

Reefer containers maintain a controlled temperature ideal for transporting perishable goods, ensuring your cargo stays fresh during transit. Dry containers lack temperature control and are suitable for general cargo such as electronics, clothing, and machinery.

Table of Comparison

| Feature | Reefer Container | Dry Container |

|---|---|---|

| Purpose | Temperature-controlled transport of perishable goods | Transport of non-perishable, dry goods |

| Temperature Control | Built-in refrigeration system (cooling or heating) | No temperature control, ambient conditions only |

| Typical Goods | Fruits, vegetables, dairy, meat, pharmaceuticals | Clothing, electronics, machinery, packaged foods |

| Cost | Higher due to refrigeration equipment and energy use | Lower; standard container cost |

| Power Supply | Requires external power source (plug-in or generator) | No power required |

| Weight | Heavier due to refrigeration unit | Lighter--basic container structure |

| Maintenance | Regular maintenance for refrigeration system | Minimal; standard container upkeep |

| Volume Capacity | Reduced internal volume due to refrigeration equipment | Maximized internal space |

| Use Cases | Cold chain logistics, frozen food transport, pharmaceuticals | General cargo shipping, bulk items, non-perishable goods |

Introduction to Reefer and Dry Containers

Reefer containers are specialized refrigerated units designed to transport temperature-sensitive goods such as fruits, pharmaceuticals, and frozen foods, maintaining a controlled environment throughout the shipping process. Dry containers, on the other hand, are standard shipping containers used for general cargo that does not require temperature regulation, including textiles, electronics, and machinery. Understanding the differences between reefer and dry containers helps you choose the right option for preserving product quality and meeting shipping requirements.

Key Differences Between Reefer and Dry Containers

Reefer containers are refrigerated units designed to transport temperature-sensitive goods such as perishables and pharmaceuticals, maintaining consistent climate control through built-in cooling systems. Dry containers, on the other hand, are standard, non-refrigerated units used primarily for shipping general cargo that does not require temperature regulation. Understanding these key differences ensures you select the right container type to protect your cargo's quality during transit.

Structure and Design Comparison

Reefer containers feature insulated walls, refrigeration units, and sealed doors to maintain controlled temperature and humidity levels, essential for transporting perishable goods like fruits, vegetables, and pharmaceuticals. Dry containers, constructed with non-insulated steel walls and simple doors, provide a versatile, cost-effective solution for shipping general cargo without temperature regulation requirements. The structural differences focus on refrigeration capabilities and insulation, making reefer containers more complex and specialized compared to the standard dry container design.

Temperature Control Capabilities

Reefer containers provide precise temperature control, allowing you to maintain consistent climates ranging from -30degC to 30degC, ideal for transporting perishable goods like food, pharmaceuticals, and chemicals. Dry containers lack temperature regulation, making them suitable for general cargo that doesn't require specific thermal conditions. Choosing the right container ensures your shipment's quality and integrity by matching the required temperature control capabilities.

Types of Cargo: Suitable Goods for Each

Reefer containers are specifically designed for transporting temperature-sensitive cargo such as perishable food, pharmaceuticals, and chemicals requiring refrigeration or freezing. Dry containers are suitable for non-perishable goods, including electronics, textiles, machinery, and packaged products that do not need temperature control. Each container type ensures optimal preservation and protection based on the nature of the cargo being shipped.

Operational Costs: Reefer vs Dry Containers

Reefer containers incur higher operational costs than dry containers due to continuous power consumption for temperature control and specialized maintenance requirements. Dry containers have lower costs because they do not need refrigeration or insulation, resulting in less energy use and simpler upkeep. Understanding these cost differences helps you optimize logistics budgeting based on cargo type and shipping duration.

Energy Consumption and Environmental Impact

Reefer containers consume significantly more energy than dry containers due to their built-in refrigeration units that maintain precise temperature control, often requiring continuous power supply. This increased energy demand results in a higher carbon footprint, especially when powered by non-renewable energy sources. In contrast, dry containers have minimal energy consumption and lower environmental impact since they do not require active cooling or heating systems.

Shipping Routes and Market Demand

Reefer containers are essential for shipping perishable goods along routes with consistent temperature control requirements, often prioritized on regions with high demand for fresh produce, pharmaceuticals, and seafood. Dry containers serve as the standard choice for non-perishable goods and dominate shipping routes with large volumes of manufactured products and raw materials. Your choice of container depends on the specific cargo needs and market demand patterns along your intended shipping route.

Maintenance and Handling Requirements

Reefer containers require specialized maintenance to ensure refrigeration units function properly, including regular inspection of cooling systems, condensers, and temperature controls. Handling reefer containers demands constant power supply and monitoring to maintain optimal cargo temperature, unlike dry containers which need standard handling and minimal maintenance beyond structural integrity checks. Proper training for technicians and handlers is essential for reefer containers to prevent spoilage and ensure compliance with temperature-sensitive shipping regulations.

Choosing the Right Container for Your Logistics Needs

Selecting the right container for your logistics needs depends on the type of cargo and temperature requirements. Reefer containers are equipped with refrigeration units that maintain a controlled environment, making them ideal for perishable goods such as food, pharmaceuticals, and chemicals. Dry containers are more suitable for non-perishable items, offering a cost-effective solution for general cargo without temperature control.

reefer container vs dry container Infographic

libmatt.com

libmatt.com