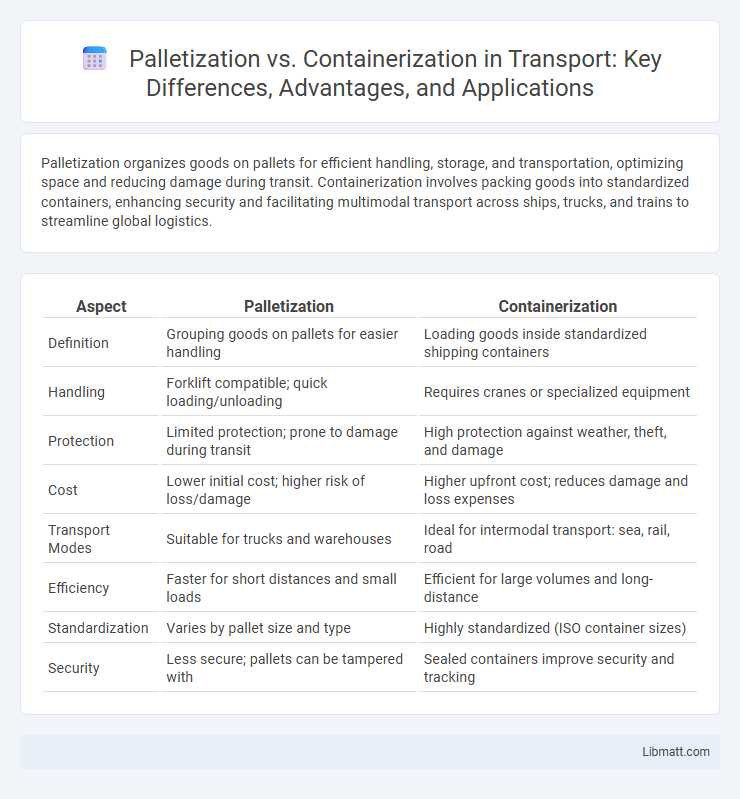

Palletization organizes goods on pallets for efficient handling, storage, and transportation, optimizing space and reducing damage during transit. Containerization involves packing goods into standardized containers, enhancing security and facilitating multimodal transport across ships, trucks, and trains to streamline global logistics.

Table of Comparison

| Aspect | Palletization | Containerization |

|---|---|---|

| Definition | Grouping goods on pallets for easier handling | Loading goods inside standardized shipping containers |

| Handling | Forklift compatible; quick loading/unloading | Requires cranes or specialized equipment |

| Protection | Limited protection; prone to damage during transit | High protection against weather, theft, and damage |

| Cost | Lower initial cost; higher risk of loss/damage | Higher upfront cost; reduces damage and loss expenses |

| Transport Modes | Suitable for trucks and warehouses | Ideal for intermodal transport: sea, rail, road |

| Efficiency | Faster for short distances and small loads | Efficient for large volumes and long-distance |

| Standardization | Varies by pallet size and type | Highly standardized (ISO container sizes) |

| Security | Less secure; pallets can be tampered with | Sealed containers improve security and tracking |

Introduction to Palletization and Containerization

Palletization involves organizing goods on pallets for efficient handling, storage, and transportation, significantly improving loading speed and reducing product damage. Containerization uses standardized containers to securely transport large quantities of goods, facilitating seamless intermodal transfer across ships, trucks, and trains. Both methods optimize supply chain logistics by enhancing packaging, handling, and shipment processes.

Definition and Overview of Palletization

Palletization is the process of stacking and securing goods on standardized pallets to facilitate efficient handling, storage, and transportation. This method enhances logistical efficiency by allowing for easier movement with forklifts and reducing the risk of product damage during transit. Palletization contrasts with containerization, which involves placing goods inside large shipping containers optimized for intermodal transport.

Definition and Overview of Containerization

Containerization refers to the standardized process of transporting goods using large, reusable steel containers that protect cargo and facilitate efficient handling across multiple transportation modes such as ships, trucks, and trains. This method enhances global trade logistics by simplifying loading, unloading, and transfer operations while improving security and reducing shipping costs. Unlike palletization, which organizes goods on pallets primarily for local or short-distance transport, containerization supports large-scale international shipping with uniform container sizes and tracking capabilities.

Key Differences Between Palletization and Containerization

Palletization involves grouping goods on pallets for easier handling and storage, optimizing warehouse space and improving loading efficiency. Containerization refers to packing goods into standardized containers for secure, intermodal transportation, reducing damage and streamlining shipping logistics. Key differences include the scale of shipment, with palletization suited for individual unit loads within warehouses and containerization designed for large-scale, multimodal transit across global supply chains.

Advantages of Palletization

Palletization improves loading efficiency by standardizing package sizes, enabling faster handling with forklifts and reducing labor costs. It minimizes product damage during transportation through better weight distribution and secure stacking. Palletized goods optimize warehouse space utilization and streamline inventory management by facilitating automated tracking and organization.

Advantages of Containerization

Containerization offers significant advantages including improved cargo security through sealed containers, standardized sizes for efficient stacking and transportation, and faster loading and unloading processes that reduce handling costs. The use of containerized shipping enables seamless intermodal transport across ships, trucks, and trains, minimizing delays and cargo damage. Enhanced cargo tracking and reduced loss rates contribute to higher operational efficiency and supply chain reliability compared to traditional palletization methods.

Challenges in Palletization and Containerization

Palletization faces challenges such as uneven weight distribution, limited load stability, and difficulties in handling irregularly shaped goods, which can lead to increased product damage during transportation. Containerization struggles with space optimization issues, container weight restrictions, and compatibility with different transportation modes, often resulting in inefficient cargo packing and higher operational costs. Both methods require careful planning and technology integration to enhance efficiency and reduce logistical complications.

Applications in Modern Supply Chain Management

Palletization enhances efficiency in modern supply chain management by enabling quick loading, unloading, and inventory control, essential for warehousing and distribution centers. Containerization optimizes international shipping through standardized containers that protect goods, reduce damage, and facilitate multimodal transport across ships, trains, and trucks. Your supply chain benefits from integrating both methods to streamline domestic handling and global freight movement, ensuring cost-effective and reliable delivery.

Choosing Between Palletization and Containerization

Choosing between palletization and containerization depends largely on the nature of your cargo, shipment volume, and handling requirements. Palletization is ideal for smaller, standardized loads that need efficient warehouse management and quick loading/unloading, while containerization suits large, bulk shipments requiring secure, weatherproof transport over long distances. Assessing your logistical priorities such as cost-efficiency, protection level, and transit mode will guide you to select the most effective method for your supply chain needs.

Future Trends in Logistic Packaging Solutions

Future trends in logistic packaging solutions emphasize increased automation and the integration of smart technologies in both palletization and containerization. Palletization is evolving with the adoption of automated stacking systems and real-time tracking sensors to enhance efficiency and reduce handling errors. Containerization is advancing through modular containers equipped with IoT devices for improved inventory management and supply chain transparency.

palletization vs containerization Infographic

libmatt.com

libmatt.com