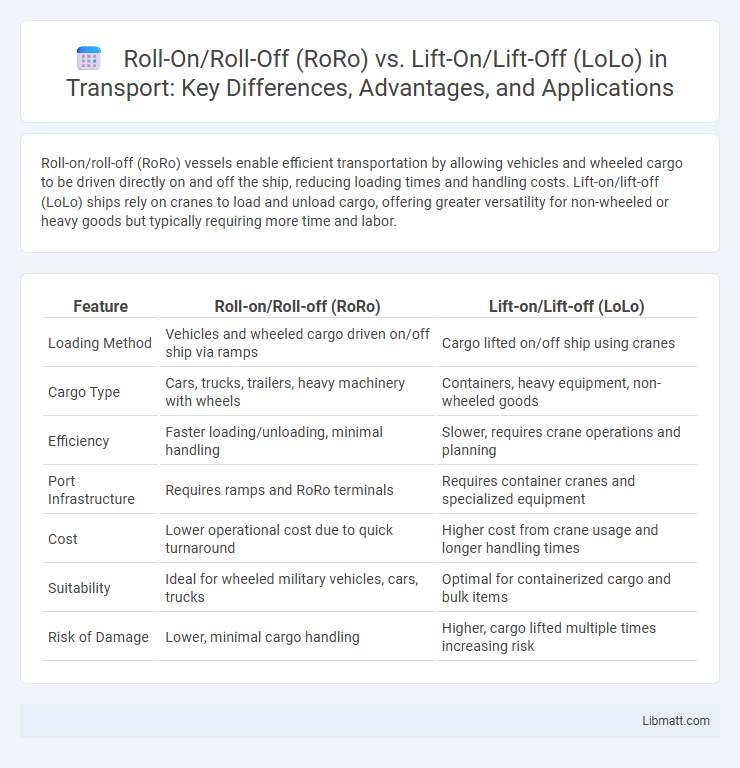

Roll-on/roll-off (RoRo) vessels enable efficient transportation by allowing vehicles and wheeled cargo to be driven directly on and off the ship, reducing loading times and handling costs. Lift-on/lift-off (LoLo) ships rely on cranes to load and unload cargo, offering greater versatility for non-wheeled or heavy goods but typically requiring more time and labor.

Table of Comparison

| Feature | Roll-on/Roll-off (RoRo) | Lift-on/Lift-off (LoLo) |

|---|---|---|

| Loading Method | Vehicles and wheeled cargo driven on/off ship via ramps | Cargo lifted on/off ship using cranes |

| Cargo Type | Cars, trucks, trailers, heavy machinery with wheels | Containers, heavy equipment, non-wheeled goods |

| Efficiency | Faster loading/unloading, minimal handling | Slower, requires crane operations and planning |

| Port Infrastructure | Requires ramps and RoRo terminals | Requires container cranes and specialized equipment |

| Cost | Lower operational cost due to quick turnaround | Higher cost from crane usage and longer handling times |

| Suitability | Ideal for wheeled military vehicles, cars, trucks | Optimal for containerized cargo and bulk items |

| Risk of Damage | Lower, minimal cargo handling | Higher, cargo lifted multiple times increasing risk |

Introduction to RoRo and LoLo Shipping

Roll-on/roll-off (RoRo) shipping utilizes specialized vessels designed for wheeled cargo such as cars, trucks, and trailers to be driven on and off the ship via ramps, significantly reducing loading times and handling costs. Lift-on/lift-off (LoLo) shipping involves the use of cranes to load and unload cargo containers, heavy machinery, or other non-wheeled goods, providing flexibility for diverse cargo types but requiring more port infrastructure and longer handling times. Both RoRo and LoLo methods serve critical roles in maritime logistics, optimized for different cargo specifications and operational efficiencies in global shipping.

Defining Roll-on/Roll-off (RoRo) Operations

Roll-on/Roll-off (RoRo) operations involve vessels designed to carry wheeled cargo such as cars, trucks, and trailers that are driven directly on and off the ship via built-in ramps. This method streamlines the loading and unloading process by eliminating the need for cranes, significantly reducing port time and labor costs. Understanding RoRo operations can help you optimize logistics for vehicles and large equipment requiring efficient and secure maritime transport.

Understanding Lift-on/Lift-off (LoLo) Processes

Lift-on/Lift-off (LoLo) shipping involves loading and unloading cargo using cranes, typically suited for containers, heavy machinery, and oversized goods that require precise handling. This process demands port infrastructure equipped with specialized lifting equipment, making it ideal for handling diverse cargo types that cannot be rolled on or off vessels. LoLo operations influence shipping efficiency and turnaround times due to the dependency on crane availability and loading complexity compared to Roll-on/Roll-off (RoRo) methods.

Key Differences Between RoRo and LoLo Shipping

RoRo shipping involves vessels designed to carry wheeled cargo such as cars, trucks, and trailers that are driven directly on and off the ship, offering faster loading and unloading processes compared to LoLo shipping. LoLo shipping relies on cranes to lift cargo containers or heavy goods on and off the vessel, suitable for varied container sizes and non-wheeled cargo types but generally requiring more time and specialized port infrastructure. The key differences include RoRo's emphasis on rollable cargo with minimal handling damage, while LoLo provides flexible handling for diverse cargo but with higher operational complexity and costs.

Types of Cargo Suited for RoRo vs LoLo

Roll-on/roll-off (RoRo) ships are ideal for wheeled cargo such as cars, trucks, trailers, and heavy machinery that can be driven directly onto the vessel, ensuring efficient loading and unloading processes. Lift-on/lift-off (LoLo) vessels are better suited for containerized goods, large equipment, and non-self-propelled cargo that require cranes or gantries for lifting, making them versatile for various types of breakbulk cargo. The choice between RoRo and LoLo depends largely on cargo dimensions, handling requirements, and port infrastructure availability.

Cost Analysis: RoRo vs LoLo

RoRo vessels generally offer lower operational costs compared to LoLo ships due to faster loading and unloading times, reducing port stay and labor expenses. LoLo operations involve higher crane usage fees and longer handling times, increasing overall shipping costs. Your choice between RoRo and LoLo should consider cargo type and cost-efficiency for optimal logistics budgeting.

Port Infrastructure and Handling Requirements

Roll-on/roll-off (RoRo) ports require specialized ramps and parking areas to facilitate the direct driving of vehicles onto and off vessels, minimizing the need for heavy lifting equipment. In contrast, lift-on/lift-off (LoLo) terminals depend on large gantry cranes and robust quay infrastructure to handle containerized cargo through vertical lifting. RoRo's streamlined vehicle movement reduces loading times but demands extensive paved areas, while LoLo supports greater cargo flexibility with increased investment in crane systems and stacking yards.

Speed and Efficiency Comparison

Roll-on/roll-off (RoRo) ships offer faster loading and unloading times compared to lift-on/lift-off (LoLo) vessels by allowing vehicles and wheeled cargo to be driven directly on and off the ship, minimizing handling requirements and port stay duration. In contrast, LoLo operations rely on cranes to lift cargo, which can be slower and more labor-intensive, affecting overall turnaround times and operational efficiency. Your choice between RoRo and LoLo should consider the balance of cargo type and the speed of port operations required for optimal supply chain performance.

Environmental Impact of RoRo and LoLo

Roll-on/roll-off (RoRo) shipping typically produces lower emissions per ton of cargo compared to lift-on/lift-off (LoLo) vessels due to more efficient loading and unloading processes that reduce port time and fuel consumption. However, LoLo offers greater flexibility for containerized and bulk cargo, which can optimize vessel utilization and reduce unnecessary voyages, indirectly benefiting the environment. You can minimize your carbon footprint by choosing the best-suited method based on cargo type and operational efficiency.

Choosing the Right Method: Factors to Consider

Choosing between roll-on/roll-off (RoRo) and lift-on/lift-off (LoLo) shipping depends on cargo type, port infrastructure, and handling efficiency. RoRo is ideal for wheeled cargo like cars and trucks, offering faster loading without cranes, while LoLo suits containerized and non-wheeled goods requiring crane operations. Key factors include vessel availability, turnaround time, cargo security, and cost implications associated with each method.

roll-on/roll-off (RoRo) vs lift-on/lift-off (LoLo) Infographic

libmatt.com

libmatt.com