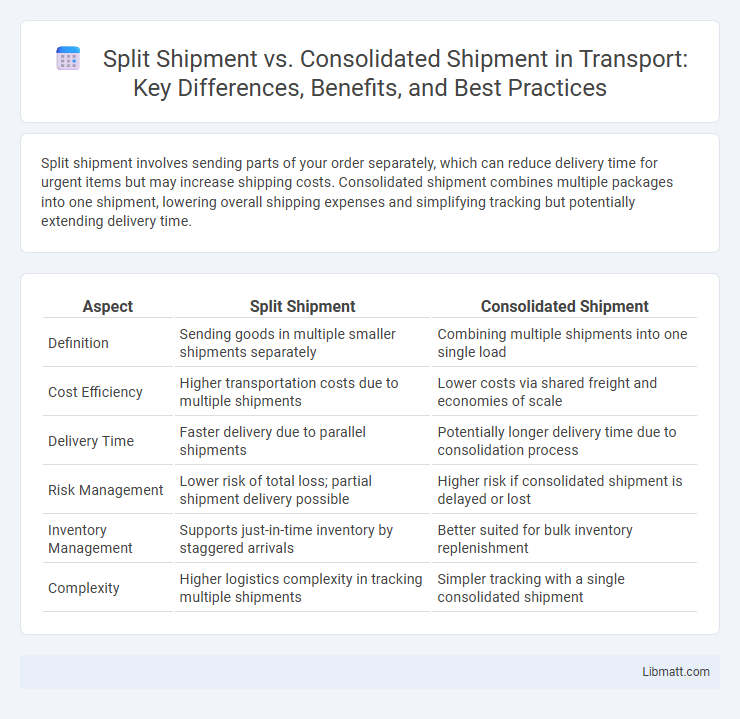

Split shipment involves sending parts of your order separately, which can reduce delivery time for urgent items but may increase shipping costs. Consolidated shipment combines multiple packages into one shipment, lowering overall shipping expenses and simplifying tracking but potentially extending delivery time.

Table of Comparison

| Aspect | Split Shipment | Consolidated Shipment |

|---|---|---|

| Definition | Sending goods in multiple smaller shipments separately | Combining multiple shipments into one single load |

| Cost Efficiency | Higher transportation costs due to multiple shipments | Lower costs via shared freight and economies of scale |

| Delivery Time | Faster delivery due to parallel shipments | Potentially longer delivery time due to consolidation process |

| Risk Management | Lower risk of total loss; partial shipment delivery possible | Higher risk if consolidated shipment is delayed or lost |

| Inventory Management | Supports just-in-time inventory by staggered arrivals | Better suited for bulk inventory replenishment |

| Complexity | Higher logistics complexity in tracking multiple shipments | Simpler tracking with a single consolidated shipment |

Understanding Split Shipments

Split shipments involve dividing a single order into multiple deliveries, which helps manage inventory levels and meet urgent demands efficiently. This method reduces lead time for critical items while allowing the remainder of the order to ship later, optimizing supply chain flexibility. Understanding split shipments can enhance Your ability to balance cost and speed, especially in complex logistics scenarios.

What Is a Consolidated Shipment?

A consolidated shipment combines multiple smaller shipments from different suppliers or orders into a single larger shipment to reduce transportation costs and improve efficiency. This method optimizes space utilization and lowers shipping fees by pooling shipments destined for the same location. Your business can benefit from consolidated shipments by minimizing handling times and streamlining logistics management.

Key Differences Between Split and Consolidated Shipments

Split shipments involve sending multiple smaller packages separately, often to meet urgent delivery needs or to accommodate inventory shortages, resulting in potentially higher shipping costs and increased tracking complexity. Consolidated shipments combine several orders or items into a single large shipment, reducing transportation expenses and simplifying logistics, but may delay delivery times due to the aggregation process. Key differences include cost efficiency, delivery speed, and inventory management impact, with split shipments offering faster individual order fulfillment and consolidated shipments optimizing overall shipping and handling expenses.

Benefits of Choosing Split Shipments

Split shipments improve delivery flexibility by allowing different parts of your order to arrive separately, reducing wait times for essential items. This approach enhances inventory management and minimizes disruption by enabling faster fulfillment from multiple warehouse locations. Businesses benefit from improved customer satisfaction and reduced risk of complete shipment delays when selecting split shipments.

Advantages of Consolidated Shipments

Consolidated shipments reduce overall transportation costs by combining multiple smaller shipments into one larger load, optimizing space usage and lowering freight charges per unit. This method enhances supply chain efficiency by minimizing the number of shipments handled, leading to fewer delays and simplified logistics management. Consolidation also supports sustainability efforts by reducing carbon emissions through fewer trips and less fuel consumption.

Cost Implications: Split vs. Consolidated Shipments

Split shipments typically incur higher transportation and handling costs due to multiple shipments requiring separate packaging, documentation, and delivery processes. Consolidated shipments reduce overall expenses by combining goods into one shipment, optimizing freight charges, and minimizing handling fees. Businesses benefit from cost savings through improved economies of scale and reduced logistical complexities in consolidated shipping.

Impact on Delivery Time and Customer Experience

Split shipments can extend delivery times as products are sent separately from multiple locations, potentially causing delays and increasing the risk of missing or late parcels. Consolidated shipments streamline the delivery process by combining items into a single package, enhancing on-time arrival and improving your overall customer experience by minimizing confusion and reducing waiting periods. Choosing the right shipment method directly influences timely delivery and customer satisfaction, essential factors in logistics management.

Common Scenarios for Split Shipments

Common scenarios for split shipments include managing inventory shortages where available stock is distributed from multiple warehouses to fulfill a single order promptly. E-commerce businesses often use split shipments to expedite delivery times by sending items from the closest fulfillment center to the customer. Another situation involves oversized or heavy products that require separate shipping methods to optimize cost and ensure safe handling.

When to Opt for Consolidated Shipping

Consolidated shipping is ideal when multiple smaller shipments need to be combined into one container to reduce overall transportation costs and improve efficiency. Businesses handling frequent, smaller orders benefit from this method as it minimizes freight charges and simplifies customs clearance processes. Choosing consolidated shipping is optimal for shipments with compatible delivery timelines and destinations to ensure smooth distribution.

Best Practices for Managing Shipments Efficiently

Implementing split shipments involves dividing orders into multiple deliveries to meet urgent demands or address inventory constraints, which enhances customer satisfaction by reducing wait times. Consolidated shipments combine multiple orders into a single delivery, optimizing transportation costs and improving supply chain efficiency through bulk handling. Best practices include leveraging advanced logistics software for real-time tracking, aligning shipment schedules with inventory management systems, and maintaining transparent communication with suppliers and customers to minimize delays and reduce operational costs.

split shipment vs consolidated shipment Infographic

libmatt.com

libmatt.com