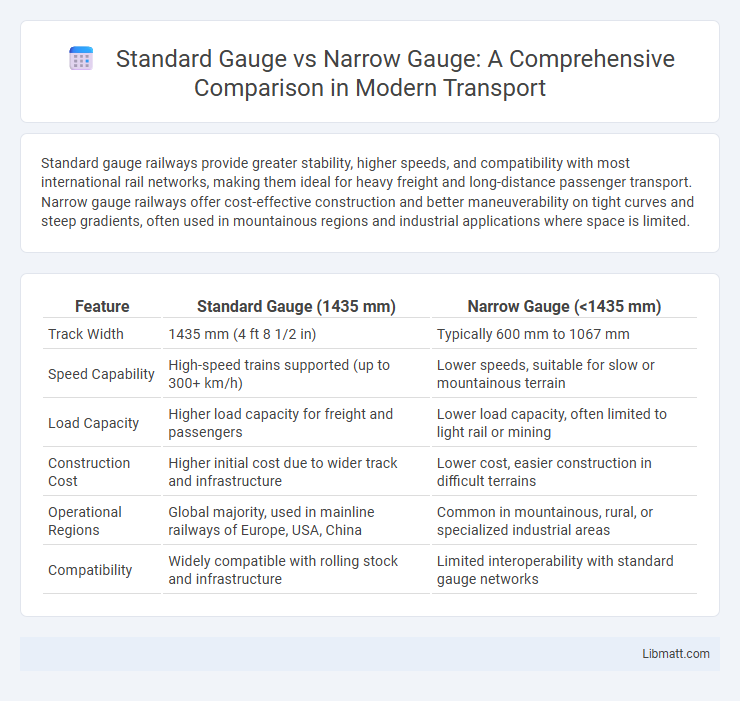

Standard gauge railways provide greater stability, higher speeds, and compatibility with most international rail networks, making them ideal for heavy freight and long-distance passenger transport. Narrow gauge railways offer cost-effective construction and better maneuverability on tight curves and steep gradients, often used in mountainous regions and industrial applications where space is limited.

Table of Comparison

| Feature | Standard Gauge (1435 mm) | Narrow Gauge (<1435 mm) |

|---|---|---|

| Track Width | 1435 mm (4 ft 8 1/2 in) | Typically 600 mm to 1067 mm |

| Speed Capability | High-speed trains supported (up to 300+ km/h) | Lower speeds, suitable for slow or mountainous terrain |

| Load Capacity | Higher load capacity for freight and passengers | Lower load capacity, often limited to light rail or mining |

| Construction Cost | Higher initial cost due to wider track and infrastructure | Lower cost, easier construction in difficult terrains |

| Operational Regions | Global majority, used in mainline railways of Europe, USA, China | Common in mountainous, rural, or specialized industrial areas |

| Compatibility | Widely compatible with rolling stock and infrastructure | Limited interoperability with standard gauge networks |

Introduction to Railway Gauges

Railway gauges define the distance between the inner sides of the two parallel rails that make up a track, directly influencing train stability, speed, and load capacity. Standard gauge measures 1,435 mm (4 ft 8 1/2 in) and is the most widely adopted worldwide, ensuring interoperability and efficient freight and passenger services. Narrow gauge, typically less than 1,435 mm, offers cost advantages and tighter curve navigation but might limit maximum speed and load capabilities on your rail network.

Defining Standard Gauge

Standard gauge, measuring 1,435 mm (4 ft 8 1/2 in), is the most widely used railway track gauge worldwide, facilitating interoperability and efficient rail transport across countries. Narrow gauge, typically ranging from 600 mm to 1,067 mm, is favored for its cost-effectiveness, adaptability to rugged terrain, and tighter curve navigation in industries like mining and mountainous regions. Understanding the distinctions in gauge size helps you optimize track design for specific operational needs and infrastructure compatibility.

Understanding Narrow Gauge

Narrow gauge railways feature track widths smaller than the standard gauge of 1,435 mm (4 ft 8 1/2 in), typically ranging from 600 mm to 1,067 mm. These railways are often used in mountainous terrain, mining operations, and regions requiring tighter curves and lower construction costs. The reduced gauge enables greater maneuverability and cost efficiency but limits speed and capacity compared to standard gauge railways.

Historical Development of Rail Gauges

The historical development of rail gauges reflects regional engineering choices driven by geography, economy, and intended use. Standard gauge, measuring 4 feet 8.5 inches (1,435 mm), became dominant worldwide due to its balance of stability and cost-efficiency, while narrow gauge lines, typically ranging from 2 feet to 3 feet 6 inches, were favored in mountainous or resource-rich areas for their tighter curves and lower construction expenses. Your understanding of this evolution highlights how rail infrastructure adapted to diverse industrial needs and terrains over time.

Track Construction and Maintenance Differences

Standard gauge tracks, measuring 1,435 mm between rails, require more extensive groundwork and heavier materials for stability and durability, making construction costs higher but maintenance less frequent due to standardized components. Narrow gauge tracks, typically ranging from 600 mm to 1,067 mm, allow for tighter curves and lighter infrastructure, resulting in lower initial construction expenses but more frequent maintenance to address increased wear and track alignment issues. The choice between standard and narrow gauge directly influences the engineering approaches, material usage, and long-term track upkeep strategies in railway projects.

Interoperability and Network Integration

Standard gauge railways, measuring 1,435 mm (4 ft 8 1/2 in), dominate global rail networks, enabling seamless interoperability and efficient network integration across countries and regions. Narrow gauge systems, varying between 600 mm and 1,067 mm, often face compatibility challenges, limiting direct connectivity and requiring transshipment or gauge-changing solutions. The widespread adoption of standard gauge facilitates unified signaling, rolling stock interchange, and reduces logistical complexities, promoting efficient freight and passenger services over extensive, interconnected networks.

Speed, Capacity, and Performance Comparison

Standard gauge railways, measuring 1,435 mm between rails, typically support higher speeds and greater load capacities than narrow gauge lines, which range from 600 mm to 1,067 mm. Standard gauge offers superior performance in terms of stability and track durability, enabling efficient transport of heavier freight and faster passenger services. Your choice between gauges impacts operational efficiency, with narrow gauge often favored for mountainous or less trafficked routes due to tighter turning radii and lower construction costs, despite reduced speed and capacity.

Cost Implications and Economic Factors

Standard gauge railways typically incur higher initial construction costs due to wider track requirements and more substantial infrastructure, but they benefit from greater speed, capacity, and interoperability, which can lead to lower operating costs over time. Narrow gauge lines require less land and materials, making them more cost-effective for rugged terrain or less trafficked routes, but they often face limitations in train size and speed that can reduce economic efficiency. Your choice between standard and narrow gauge should consider long-term operational expenses and the specific economic context of your rail project.

Applications and Geographic Suitability

Standard gauge railways, measuring 1,435 mm (4 ft 8 1/2 in), are widely used for high-speed rail, heavy freight, and urban transit systems due to their stability and compatibility with global networks, making them suitable for developed regions with high traffic demand such as North America, Europe, and parts of Asia. Narrow gauge railways, typically ranging from 600 mm to 1,067 mm, excel in rugged terrains and mountainous areas, offering cost-effective construction and sharper curve negotiation, favored in regions like Africa, South America, and parts of Southeast Asia where geographic challenges and lower traffic volumes are prevalent. The choice between standard and narrow gauge depends on factors such as terrain complexity, economic resources, and intended rail system capacity.

Future Trends in Rail Gauge Standards

Future trends in rail gauge standards indicate a gradual shift towards standard gauge (1,435 mm) due to its global interoperability and compatibility with high-speed rail technologies. Emerging rail infrastructure projects in Asia and Africa increasingly adopt standard gauge to facilitate international trade and cross-border connectivity. However, narrow gauge systems (below 1,435 mm) remain relevant in mountainous or regional lines where cost efficiency and terrain adaptability are prioritized.

standard gauge vs narrow gauge Infographic

libmatt.com

libmatt.com