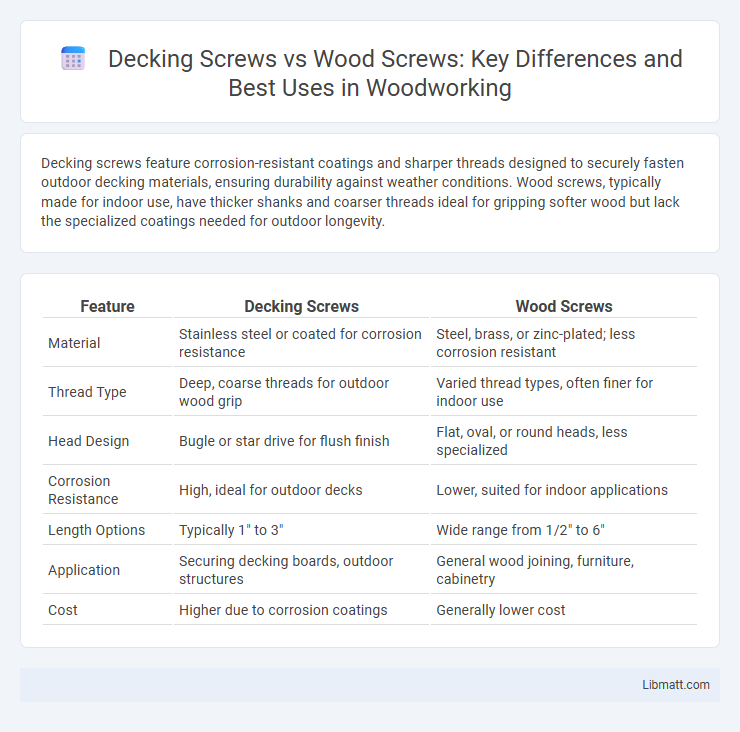

Decking screws feature corrosion-resistant coatings and sharper threads designed to securely fasten outdoor decking materials, ensuring durability against weather conditions. Wood screws, typically made for indoor use, have thicker shanks and coarser threads ideal for gripping softer wood but lack the specialized coatings needed for outdoor longevity.

Table of Comparison

| Feature | Decking Screws | Wood Screws |

|---|---|---|

| Material | Stainless steel or coated for corrosion resistance | Steel, brass, or zinc-plated; less corrosion resistant |

| Thread Type | Deep, coarse threads for outdoor wood grip | Varied thread types, often finer for indoor use |

| Head Design | Bugle or star drive for flush finish | Flat, oval, or round heads, less specialized |

| Corrosion Resistance | High, ideal for outdoor decks | Lower, suited for indoor applications |

| Length Options | Typically 1" to 3" | Wide range from 1/2" to 6" |

| Application | Securing decking boards, outdoor structures | General wood joining, furniture, cabinetry |

| Cost | Higher due to corrosion coatings | Generally lower cost |

Introduction to Decking Screws vs Wood Screws

Decking screws feature corrosion-resistant coatings and threads designed for outdoor wood applications, providing superior grip and durability compared to standard wood screws. Wood screws, typically used for indoor carpentry, have a simpler design suited for general woodworking tasks but lack the weather-resistant properties crucial for decking projects. Choosing decking screws ensures enhanced structural integrity and longevity in exterior environments where moisture and weather exposure are factors.

Key Differences Between Decking and Wood Screws

Decking screws feature corrosion-resistant coatings and specialized threads designed for hardwood durability and outdoor exposure, whereas wood screws typically lack these features, making them less suitable for exterior projects. Decking screws often have a bugle or trim head to prevent wood splitting and provide a flush finish, while wood screws usually have flat or oval heads for general carpentry use. The thread style on decking screws is usually deeper and more aggressive to ensure a stronger hold in dense decking materials compared to the shallower threads on standard wood screws.

Material Composition: Decking Screws vs Wood Screws

Decking screws are typically made from stainless steel or coated with corrosion-resistant materials such as epoxy or ceramic to withstand outdoor weather conditions, while wood screws usually consist of plain steel or zinc-plated steel, making them less durable in moist environments. The material composition of decking screws enhances their resistance to rust, ensuring long-lasting structural integrity for outdoor decks. Choosing the right screw material for your project prevents premature failure and maintains the stability of your wooden construction.

Head and Thread Design Comparison

Decking screws feature a corrosion-resistant coating with a bugle-shaped head designed to prevent wood splitting and ensure a flush finish, while wood screws often have a flat or oval head with a less specialized coating. The threads on decking screws are typically deeper and sharper, promoting superior grip and holding power in composite or hardwood decking materials compared to the shallower threads of standard wood screws. Your choice between these screws should account for the material type and desired durability, as decking screws are optimized for outdoor exposure and strength.

Corrosion Resistance and Durability

Decking screws feature specialized coatings such as ceramic or stainless steel to provide superior corrosion resistance, especially in outdoor and moisture-prone environments, extending the lifespan of decking installations. Wood screws, typically made from plain steel or zinc-coated materials, offer less protection against rust and corrosion, making them less durable for exterior applications. For long-term durability in exposed conditions, decking screws are the preferable choice due to their enhanced resistance to weathering and structural integrity maintenance.

Application Suitability: Where Each Screw Excels

Decking screws excel in outdoor applications due to their corrosion-resistant coatings and hardened construction, making them ideal for fastening composite or pressure-treated wood decks. Wood screws are better suited for indoor woodworking projects where high holding power and minimal wood splitting are required, such as furniture assembly or cabinetry. Choosing the right screw depends on environmental exposure and the specific wood type to ensure durability and structural integrity.

Installation Process: Decking Screws vs Wood Screws

Decking screws feature a corrosion-resistant coating and sharp, self-tapping threads that facilitate faster and easier installation into outdoor timber compared to wood screws, which often require pre-drilling to avoid splitting. Wood screws typically have a smoother shank and are designed for general woodworking, demanding more careful pilot hole preparation to ensure proper fastening. Your choice between decking screws and wood screws impacts installation speed and durability, especially in exterior decking projects where moisture resistance is critical.

Cost Considerations and Budgeting

Decking screws typically cost more than standard wood screws due to their corrosion-resistant coatings and specialized design for outdoor durability. Your budgeting should account for the higher upfront expense but consider that decking screws reduce maintenance and replacement costs over time. Choosing the right screw balances initial investment with long-term performance, especially in exterior woodworking projects.

Pros and Cons of Decking Screws vs Wood Screws

Decking screws feature corrosion-resistant coatings and coarse threads designed to securely fasten decking boards, offering superior holding power and durability in outdoor environments. Wood screws provide versatility with a variety of thread types suitable for general woodworking but may lack the rust resistance and strength needed for long-term deck performance. Choosing decking screws enhances your deck's longevity and stability, while wood screws might suffice for indoor or non-exposed applications.

Conclusion: Choosing the Right Screw for Your Project

Decking screws offer superior corrosion resistance and a design tailored to withstand outdoor weather conditions, making them ideal for exterior projects like decks and patios. Wood screws, while versatile and suitable for indoor woodworking, lack the durability needed for prolonged exposure to moisture and outdoor elements. Choosing the right screw ensures your project's stability and longevity, with decking screws providing enhanced performance for outdoor applications while wood screws excel in interior wood joinery.

Decking screws vs wood screws Infographic

libmatt.com

libmatt.com