Core plugs seal the holes left during the engine block casting process to prevent coolant or oil leaks, whereas dowel plugs are primarily used to precisely align engine components during assembly. Understanding the distinction helps you ensure proper engine maintenance and repairs.

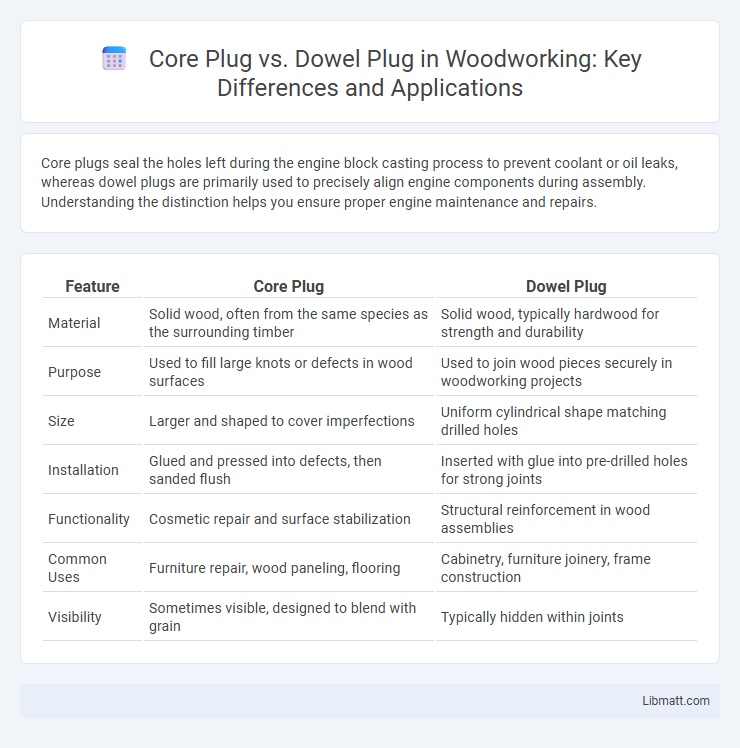

Table of Comparison

| Feature | Core Plug | Dowel Plug |

|---|---|---|

| Material | Solid wood, often from the same species as the surrounding timber | Solid wood, typically hardwood for strength and durability |

| Purpose | Used to fill large knots or defects in wood surfaces | Used to join wood pieces securely in woodworking projects |

| Size | Larger and shaped to cover imperfections | Uniform cylindrical shape matching drilled holes |

| Installation | Glued and pressed into defects, then sanded flush | Inserted with glue into pre-drilled holes for strong joints |

| Functionality | Cosmetic repair and surface stabilization | Structural reinforcement in wood assemblies |

| Common Uses | Furniture repair, wood paneling, flooring | Cabinetry, furniture joinery, frame construction |

| Visibility | Sometimes visible, designed to blend with grain | Typically hidden within joints |

Introduction to Core Plug and Dowel Plug

Core plugs, also known as freeze plugs, are circular metal seals used to close holes in engine blocks created during the casting process, preventing coolant leaks and protecting against corrosion. Dowel plugs, typically cylindrical pins, serve as precise alignment components in machinery, ensuring accurate positioning of parts and maintaining structural integrity. Both plugs are critical in automotive and industrial applications for sealing and aligning components, but they differ fundamentally in function and design.

Defining Core Plug: Purpose and Applications

Core plugs, also known as freeze plugs or expansion plugs, are designed to seal the openings left in engine blocks during the manufacturing process, preventing coolant leaks and maintaining optimal engine temperature. These plugs are typically made from metal or rubber and are crucial in automotive and machinery applications where engine cooling systems require secure sealing. Your engine's reliability depends on properly installed core plugs to avoid coolant loss and potential overheating issues.

What is a Dowel Plug? Key Features and Uses

A dowel plug is a cylindrical fastener designed to fit snugly into pre-drilled holes to align, join, or reinforce two components, commonly used in woodworking, metalworking, and construction. Key features include precise diameter for tight fitting, durability from materials like hardwood or metal, and ease of installation to provide structural stability and prevent movement between parts. Dowel plugs are widely used for aligning machine parts, reinforcing joints in furniture assembly, and filling holes where screws or bolts are not desirable.

Material Differences: Core Plug vs Dowel Plug

Core plugs are typically made from steel or brass and designed to seal holes in engine blocks, offering resistance to corrosion and high temperatures. Dowel plugs, often crafted from hardened steel, provide precise alignment and positioning in machinery, emphasizing mechanical strength and dimensional accuracy. Material selection reflects their distinct functions: core plugs prioritize corrosion resistance, while dowel plugs focus on durability and precision fit.

Manufacturing Processes and Compatibility

Core plugs, typically manufactured through stamping and deep drawing from steel or brass sheets, are designed for sealing engine block openings created during casting. Dowel plugs, produced via precision machining or cold heading from hardened steel, serve primarily for alignment purposes in assembly rather than sealing. Compatibility depends on engine design requirements, with core plugs fitting standard coolant passages, while dowel plugs ensure precise component positioning without fluid sealing functions.

Installation Methods Compared

Core plugs install by pressing into drilled or punched holes in engine blocks, creating a fluid-tight seal using rubber or metal materials that expand with heat. Dowel plugs, on the other hand, are typically solid metal pins inserted into pre-machined dowel holes to precisely align engine components and provide structural positioning rather than sealing. Your choice between these plugs depends on whether the application requires sealing coolant passages or exact mechanical alignment.

Performance and Durability Analysis

Core plugs and dowel plugs differ significantly in performance and durability, with core plugs designed for sealing engine block openings to prevent coolant leaks under high pressure and temperature conditions. Dowel plugs, primarily used for precise alignment of engine components, offer limited sealing capability but excel in maintaining structural integrity during assembly and operation. Your choice should consider that core plugs require materials resistant to corrosion and thermal stress, while dowel plugs prioritize strength and dimensional stability to enhance overall engine reliability.

Cost Considerations: Core Plug vs Dowel Plug

Core plugs typically offer a lower cost solution compared to dowel plugs due to simpler manufacturing processes and common materials like steel or brass. Dowel plugs, often made from more durable or specialized materials, may incur higher initial costs but provide enhanced durability and alignment benefits in precision applications. Your choice between core plug and dowel plug should weigh upfront expenses against long-term performance needs for the best cost-effectiveness.

Industry Applications and Case Uses

Core plugs are commonly used in automotive engine blocks to seal cooling system passages and prevent coolant leaks, playing a critical role in automotive manufacturing and repair. Dowel plugs serve primarily as precise alignment tools in machinery assembly and equipment manufacturing, ensuring accurate positioning of components in aerospace and heavy machinery industries. Your choice between core plugs and dowel plugs depends on whether sealing or alignment is required in your specific industrial application.

Choosing the Right Plug: Core vs Dowel

Selecting the right type of plug depends on the application requirements: core plugs provide a reliable seal in engine blocks to prevent fluid leaks, while dowel plugs offer precise alignment in mechanical assemblies. Core plugs are typically used in automotive and machinery cooling systems where corrosion resistance and leak prevention are critical. Dowel plugs ensure structural accuracy and prevent component misalignment in manufacturing processes, making choice dependent on whether sealing or alignment is the primary function.

Core plug vs Dowel plug Infographic

libmatt.com

libmatt.com