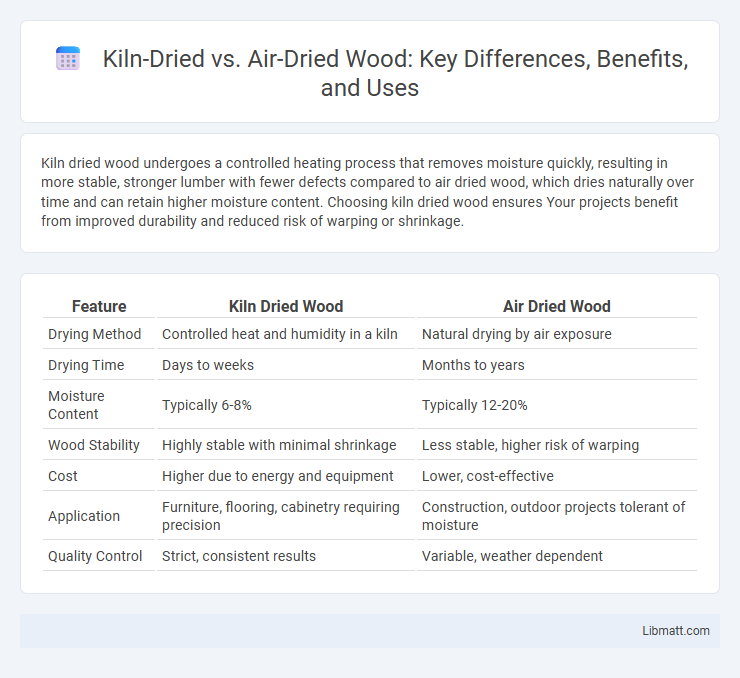

Kiln dried wood undergoes a controlled heating process that removes moisture quickly, resulting in more stable, stronger lumber with fewer defects compared to air dried wood, which dries naturally over time and can retain higher moisture content. Choosing kiln dried wood ensures Your projects benefit from improved durability and reduced risk of warping or shrinkage.

Table of Comparison

| Feature | Kiln Dried Wood | Air Dried Wood |

|---|---|---|

| Drying Method | Controlled heat and humidity in a kiln | Natural drying by air exposure |

| Drying Time | Days to weeks | Months to years |

| Moisture Content | Typically 6-8% | Typically 12-20% |

| Wood Stability | Highly stable with minimal shrinkage | Less stable, higher risk of warping |

| Cost | Higher due to energy and equipment | Lower, cost-effective |

| Application | Furniture, flooring, cabinetry requiring precision | Construction, outdoor projects tolerant of moisture |

| Quality Control | Strict, consistent results | Variable, weather dependent |

Understanding Kiln Dried and Air Dried Wood

Kiln dried wood undergoes a controlled heating process to rapidly remove moisture, resulting in consistent moisture content and increased stability, making it ideal for furniture and flooring. Air dried wood naturally loses moisture over several months through exposure to ambient air, which can lead to variable moisture levels and potential warping. Your choice between kiln dried and air dried wood should consider project requirements for moisture content, durability, and dimensional stability.

The Drying Process: Kiln vs Air Drying

Kiln drying involves using controlled heat and humidity within a chamber to rapidly reduce moisture content in wood, ensuring a consistent and precise drying process. Air drying relies on natural airflow and ambient conditions to gradually evaporate moisture, often taking several months and resulting in less uniform dryness. Your choice between kiln dried and air dried wood depends on the need for speed, moisture control, and the specific application of the timber.

Moisture Content Differences

Kiln dried wood typically has a moisture content ranging from 6% to 8%, which ensures greater stability and resistance to warping compared to air dried wood that usually contains 12% to 20% moisture. The controlled environment in kiln drying accelerates moisture reduction, resulting in more consistent and predictable lumber quality. Air drying depends on ambient conditions, leading to slower moisture loss and potentially higher residual moisture content.

Speed and Efficiency of Drying Methods

Kiln drying typically reduces moisture content in wood within a few days through controlled heat and airflow, significantly speeding up the drying process compared to air drying, which can take several months depending on environmental conditions. The controlled environment of kiln drying minimizes the risk of warping, splitting, and fungal growth, enhancing overall efficiency and producing uniform moisture content. Air drying relies on natural ventilation and ambient weather, making it slower and less predictable but more energy-efficient and cost-effective for slower production cycles.

Impact on Wood Stability and Warping

Kiln dried wood offers superior stability and significantly reduces the risk of warping due to its controlled drying process that rapidly removes moisture. Air dried wood, while more natural, retains higher moisture content and is more prone to uneven drying, increasing the likelihood of warping and dimensional changes. Choosing kiln dried lumber enhances long-term structural integrity and minimizes deformation in woodworking projects.

Effects on Wood Strength and Durability

Kiln dried wood undergoes a controlled heating process that reduces moisture content to a precise level, significantly enhancing its strength and durability by preventing warping, splitting, and fungal growth. Air dried wood retains higher moisture levels, making it more susceptible to shrinkage, deformation, and decay over time. Your choice between kiln dried and air dried will impact the long-term performance and structural integrity of the wood in your projects.

Environmental Considerations

Kiln dried wood consumes more energy due to the use of controlled heat chambers, resulting in a higher carbon footprint compared to air dried wood, which relies on natural airflow and sunlight, making it a more eco-friendly option. However, kiln drying reduces the risk of mold and insect infestation, potentially extending the wood's lifespan and lowering the need for replacement, indirectly benefiting the environment. Choosing air dried wood supports sustainable practices by minimizing fossil fuel consumption, whereas kiln dried options can integrate renewable energy to mitigate environmental impacts.

Cost Comparison: Kiln Dried vs Air Dried

Kiln dried lumber generally costs more than air dried wood due to the energy-intensive drying process and specialized equipment required, which increases production expenses. Air dried wood is more economical as it relies on natural weather conditions to reduce moisture content over time, minimizing operational costs. However, kiln drying offers faster turnaround and more consistent moisture levels, potentially reducing waste and long-term costs despite the higher initial price.

Best Applications for Each Drying Method

Kiln-dried wood is ideal for indoor furniture, flooring, and cabinetry because its low moisture content enhances stability and reduces the risk of warping or mold. Air-dried wood suits outdoor projects, rustic furniture, and construction where slight moisture variation is acceptable and natural drying is preferred. Your choice depends on the specific requirements of your project, balancing speed, cost, and final wood quality.

Choosing the Right Wood for Your Project

Kiln dried wood offers precise moisture control, reducing the risk of warping and making it ideal for indoor furniture and cabinetry where stability is crucial. Air dried wood, with its natural drying process, retains more moisture, offering a rustic aesthetic suitable for outdoor projects or certain craft applications. Understanding the moisture content and drying method helps you select the best wood to ensure durability and performance for your specific project needs.

Kiln dried vs Air dried Infographic

libmatt.com

libmatt.com