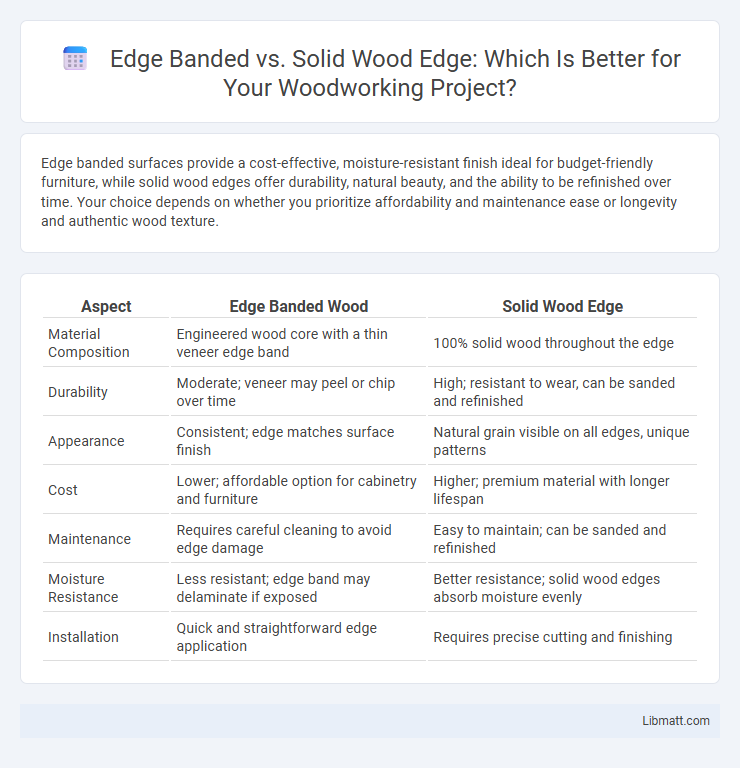

Edge banded surfaces provide a cost-effective, moisture-resistant finish ideal for budget-friendly furniture, while solid wood edges offer durability, natural beauty, and the ability to be refinished over time. Your choice depends on whether you prioritize affordability and maintenance ease or longevity and authentic wood texture.

Table of Comparison

| Aspect | Edge Banded Wood | Solid Wood Edge |

|---|---|---|

| Material Composition | Engineered wood core with a thin veneer edge band | 100% solid wood throughout the edge |

| Durability | Moderate; veneer may peel or chip over time | High; resistant to wear, can be sanded and refinished |

| Appearance | Consistent; edge matches surface finish | Natural grain visible on all edges, unique patterns |

| Cost | Lower; affordable option for cabinetry and furniture | Higher; premium material with longer lifespan |

| Maintenance | Requires careful cleaning to avoid edge damage | Easy to maintain; can be sanded and refinished |

| Moisture Resistance | Less resistant; edge band may delaminate if exposed | Better resistance; solid wood edges absorb moisture evenly |

| Installation | Quick and straightforward edge application | Requires precise cutting and finishing |

Introduction to Edge Banding and Solid Wood Edges

Edge banding is a thin strip of material applied to the exposed edges of furniture or cabinetry to protect and enhance the appearance of particleboard or MDF surfaces. Solid wood edges, made from a continuous piece of hardwood, offer durability and a natural look but can be more expensive and susceptible to warping. Understanding the differences between edge banding and solid wood edges helps you choose the best option for your project's aesthetic and budget requirements.

Material Composition: Edge Band vs. Solid Wood

Edge banding typically consists of thin strips of PVC, ABS, or wood veneer applied to the edges of engineered wood panels, enhancing durability and moisture resistance. Solid wood edges are crafted from natural hardwood or softwood, providing authentic grain patterns and superior strength but requiring more maintenance. The choice between edge band and solid wood edges impacts both the material longevity and the aesthetic quality of furniture or cabinetry.

Visual Appearance and Style Comparison

Edge banded surfaces offer a consistent, clean appearance with a smooth finish ideal for modern designs, while solid wood edges display natural grain patterns and unique imperfections that enhance rustic or traditional styles. The uniformity of edge banding allows for precise color and texture matching, maintaining a seamless look across furniture pieces. Your choice between edge banded and solid wood edges influences the overall aesthetic, balancing sleek modernity against authentic, organic character.

Durability and Longevity Factors

Edge banded surfaces provide enhanced resistance to moisture and impact, reducing the risk of chipping and swelling over time compared to untreated solid wood edges. Solid wood edges, while naturally durable and capable of being sanded and refinished multiple times, are more susceptible to warping and denting when exposed to fluctuating humidity and physical stress. Choosing between these options depends on the environment and usage intensity, with edge banding offering superior long-term protection in high-moisture or high-traffic settings.

Cost Analysis: Edge Banding vs. Solid Wood Edges

Edge banding offers a cost-effective solution compared to solid wood edges, as it requires less material and reduces labor expenses during application. Solid wood edges typically incur higher costs due to the price of lumber and the additional craftsmanship needed for shaping and finishing. Long-term maintenance costs may favor edge banding since solid wood edges can be prone to damage, requiring more frequent repairs or refinishing.

Installation Process and Skill Requirements

Edge banded surfaces offer a simpler and faster installation process compared to solid wood edges, requiring basic tooling such as a trimmer or iron-on applicator, making it accessible for DIY enthusiasts. Solid wood edges demand more advanced woodworking skills, precise cutting, sanding, and finishing to ensure a seamless appearance and durability, often necessitating professional installation. You should select edge banding for cost-effective, quick applications, while solid wood edges suit projects where craftsmanship and longevity are priorities.

Maintenance and Repair Considerations

Edge-banded surfaces require less frequent maintenance and are easier to clean due to their resistance to moisture and staining, making repairs simpler and more cost-effective. Solid wood edges demand regular sealing and refinishing to prevent warping and damage from environmental changes, while repairs can be more complex and costly since they often involve sanding, staining, or replacing entire sections. Choosing between edge banded and solid wood edges depends on the balance between desired durability, ease of upkeep, and long-term repair considerations.

Environmental Impact and Sustainability

Edge banded materials typically use a thin layer of plastic or wood veneer applied over MDF or particleboard, which often contains formaldehyde-based adhesives, raising concerns about indoor air quality and limited recyclability. Solid wood edges come from natural, renewable timber sources, offering better biodegradability and lower VOC emissions, especially when sourced from sustainably managed forests certified by FSC or PEFC. The environmental impact favors solid wood edges for sustainability due to their longer lifespan, repairability, and potential for reuse compared to the synthetic adhesives and shorter lifespan of edge banded surfaces.

Best Applications for Edge Banding

Edge banding is ideal for furniture and cabinetry where cost efficiency and moisture resistance are priorities, such as in kitchens, offices, and retail fixtures, offering a consistent, durable finish on MDF or particleboard. It excels in applications requiring quick installation and uniform appearance, making it suitable for flat panel surfaces and modular units. Edge banding also provides protection against chipping and enhances the aesthetic appeal without the expense of solid wood edges in high-volume production.

Best Uses for Solid Wood Edge

Solid wood edges are ideal for high-end furniture, cabinetry, and custom woodworking projects requiring durability and an authentic wood appearance. They provide superior strength, natural grain continuity, and the ability to be sanded and refinished multiple times compared to edge banding. Solid wood edges are preferred for tabletops, doors, and shelves where longevity and aesthetic appeal are critical.

Edge banded vs solid wood edge Infographic

libmatt.com

libmatt.com