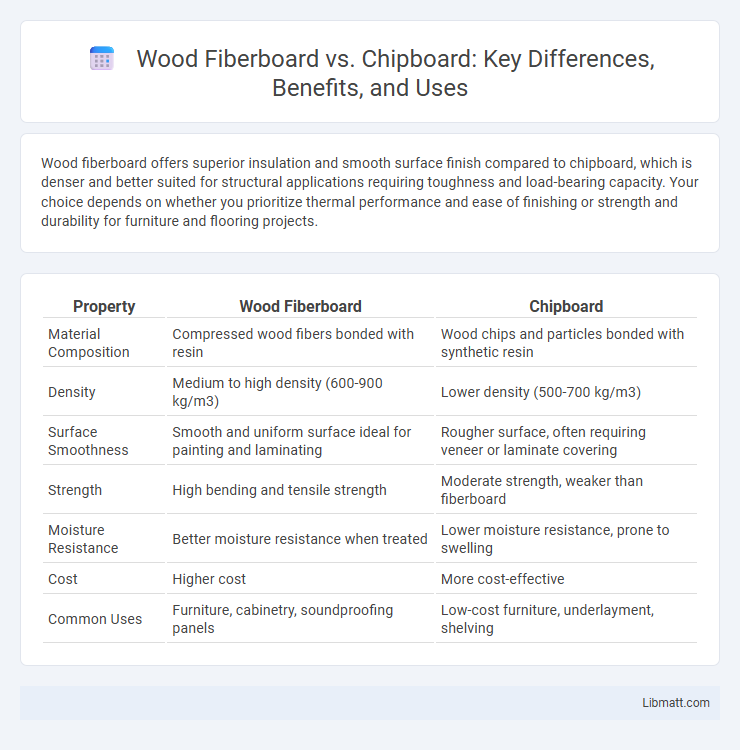

Wood fiberboard offers superior insulation and smooth surface finish compared to chipboard, which is denser and better suited for structural applications requiring toughness and load-bearing capacity. Your choice depends on whether you prioritize thermal performance and ease of finishing or strength and durability for furniture and flooring projects.

Table of Comparison

| Property | Wood Fiberboard | Chipboard |

|---|---|---|

| Material Composition | Compressed wood fibers bonded with resin | Wood chips and particles bonded with synthetic resin |

| Density | Medium to high density (600-900 kg/m3) | Lower density (500-700 kg/m3) |

| Surface Smoothness | Smooth and uniform surface ideal for painting and laminating | Rougher surface, often requiring veneer or laminate covering |

| Strength | High bending and tensile strength | Moderate strength, weaker than fiberboard |

| Moisture Resistance | Better moisture resistance when treated | Lower moisture resistance, prone to swelling |

| Cost | Higher cost | More cost-effective |

| Common Uses | Furniture, cabinetry, soundproofing panels | Low-cost furniture, underlayment, shelving |

Introduction to Wood Fiberboard and Chipboard

Wood fiberboard is a versatile engineered wood product made from wood fibers bonded under heat and pressure, offering smooth surfaces and strong structural properties. Chipboard, also known as particleboard, is composed of wood chips and resin, providing a cost-effective option primarily used in furniture and cabinetry. Both materials serve distinct purposes in construction and manufacturing due to differences in density, strength, and texture.

Material Composition and Manufacturing Process

Wood fiberboard is composed of wood fibers bonded together using heat, pressure, and adhesives, creating a dense and uniform panel ideal for insulation and furniture applications. Chipboard, made from wood chips, sawmill shavings, and resin, undergoes compression and binding to form a less dense, cost-effective material often used in cabinetry and flooring underlayment. The manufacturing process of fiberboard emphasizes refining fibers to achieve smoothness and strength, whereas chipboard production focuses on compacting larger wood particles to reduce waste and enhance structural rigidity.

Key Physical and Mechanical Properties

Wood fiberboard exhibits higher density and greater dimensional stability compared to chipboard, making it more resistant to moisture and deformation under load. Chipboard, composed of wood chips and resin, offers moderate strength but is more prone to swelling and reduced mechanical integrity when exposed to humidity. The superior tensile strength and impact resistance of wood fiberboard make it preferable for applications requiring durability and load-bearing capacity.

Strength and Durability Comparison

Wood fiberboard offers superior strength and durability compared to chipboard due to its denser composition and finer wood fibers, resulting in better load-bearing capacity and resistance to impact. Chipboard, made from larger wood chips bonded with resin, tends to be less dense and more prone to sagging or damage under heavy weight or prolonged use. Your choice should prioritize wood fiberboard if long-term durability and structural integrity are critical for your project.

Surface Finish and Aesthetic Appeal

Wood fiberboard typically offers a smoother surface finish compared to chipboard due to its finer fibers, making it ideal for high-quality painting or laminating. Chipboard has a rougher texture and visible wood chip patterns, which may require additional treatment to achieve an attractive aesthetic appeal. You can enhance the visual appearance of both materials by applying veneers or specialized coatings tailored to your design needs.

Applications in Furniture and Construction

Wood fiberboard offers superior insulation and soundproofing qualities, making it a preferred choice for interior wall panels and furniture backing in residential and commercial construction. Chipboard, known for its density and affordability, is commonly used in low-cost furniture production, shelving, and subflooring where structural strength is essential but aesthetic finishes can be applied separately. Both materials serve critical roles in furniture manufacturing and construction, with fiberboard excelling in durability and finish quality, while chipboard provides cost-effective solutions for structural frameworks.

Environmental Impact and Sustainability

Wood fiberboard is generally more sustainable than chipboard due to its use of finer wood fibers, which often come from recycled wood and lower-impact sources, reducing deforestation. Chipboard production relies heavily on wood chips and adhesive resins that may emit formaldehyde, increasing its environmental footprint. Both materials can be recycled, but wood fiberboard's lower reliance on toxic adhesives makes it a more eco-friendly option for environmentally conscious construction and furniture manufacturing.

Cost and Value Analysis

Wood fiberboard generally offers better value due to its higher density and durability, costing slightly more than chipboard but providing enhanced strength and moisture resistance. Chipboard is typically cheaper, making it suitable for budget-friendly projects, but it is less durable and more prone to damage from moisture and heavy loads. Considering long-term performance, wood fiberboard's higher initial cost often results in lower maintenance and replacement expenses, increasing overall cost-effectiveness.

Maintenance and Longevity

Wood fiberboard offers superior durability and requires less frequent maintenance due to its dense composition and resistance to moisture and pests. Chipboard, being more susceptible to swelling and damage from humidity, demands regular sealing and careful handling to prolong its lifespan. Proper upkeep of wood fiberboard can extend its usability by decades, while chipboard typically has a shorter service life and higher vulnerability to wear and tear.

Choosing the Right Board for Your Project

Wood fiberboard offers superior insulation and smooth surface ideal for painting or finishing, while chipboard provides high structural strength at a lower cost, making it suitable for load-bearing applications. Your choice depends on project needs: fiberboard excels in interior design and soundproofing, whereas chipboard is perfect for furniture and cabinetry requiring durability. Evaluate factors like moisture resistance, finish quality, and budget to select the right board for optimal results.

Wood fiberboard vs chipboard Infographic

libmatt.com

libmatt.com