A dovetail joint offers superior strength and aesthetic appeal due to its interlocking trapezoidal shapes, making it ideal for high-stress woodworking projects like drawers and cabinets. Your choice between dovetail and box joints should consider the ease of fabrication, as box joints are simpler to cut with basic tools but provide less mechanical resistance compared to dovetails.

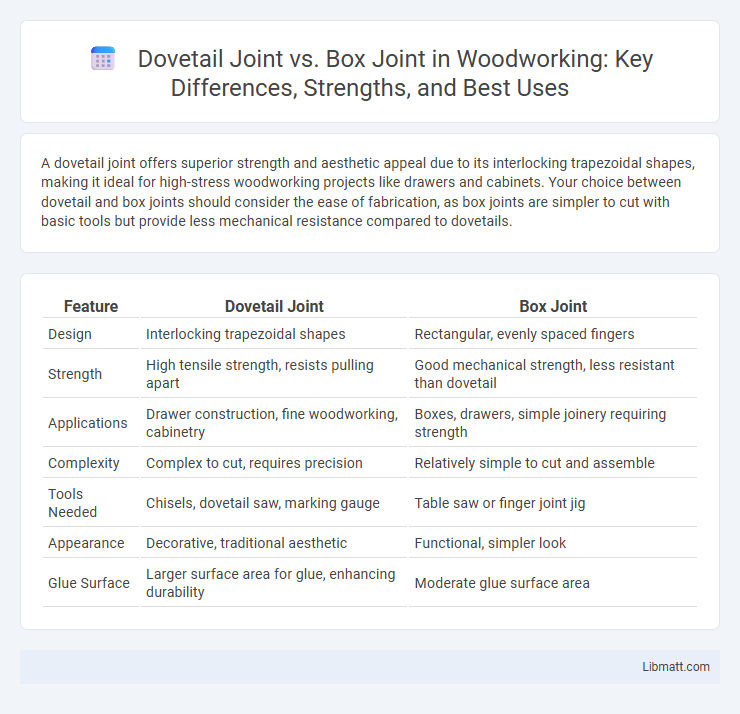

Table of Comparison

| Feature | Dovetail Joint | Box Joint |

|---|---|---|

| Design | Interlocking trapezoidal shapes | Rectangular, evenly spaced fingers |

| Strength | High tensile strength, resists pulling apart | Good mechanical strength, less resistant than dovetail |

| Applications | Drawer construction, fine woodworking, cabinetry | Boxes, drawers, simple joinery requiring strength |

| Complexity | Complex to cut, requires precision | Relatively simple to cut and assemble |

| Tools Needed | Chisels, dovetail saw, marking gauge | Table saw or finger joint jig |

| Appearance | Decorative, traditional aesthetic | Functional, simpler look |

| Glue Surface | Larger surface area for glue, enhancing durability | Moderate glue surface area |

Introduction to Dovetail and Box Joints

Dovetail joints feature interlocking, trapezoidal pins and tails that provide exceptional tensile strength and aesthetic appeal, commonly used in high-quality cabinetry and drawer construction. Box joints, also known as finger joints, consist of rectangular interlocking fingers that create a strong, straightforward connection ideal for box-like structures and woodworking projects requiring durability and ease of assembly. Both joints optimize mechanical strength without relying heavily on adhesives, with dovetail joints favored for intricate craftsmanship and box joints prized for speed and simplicity.

What is a Dovetail Joint?

A dovetail joint is a woodworking technique characterized by interlocking trapezoidal pins and tails that create a strong mechanical bond without relying solely on adhesives. This joint is commonly used in drawer construction and fine cabinetry due to its resistance to being pulled apart. Its unique shape distributes stress evenly, providing superior durability compared to simpler joints like box joints.

What is a Box Joint?

A box joint, also known as a finger joint, is a woodworking technique where multiple rectangular fingers are cut into two pieces of wood and interlocked to form a strong, square corner. This joint offers excellent tensile strength and a large gluing surface, making it ideal for drawers, boxes, and carcass construction. Your choice between a box joint and a dovetail joint depends on the desired appearance and mechanical strength of the finished project.

Key Differences Between Dovetail and Box Joints

Dovetail joints feature interlocking trapezoidal pins and tails that provide superior tensile strength and resistance to pulling apart, making them ideal for drawer construction and fine woodworking. Box joints consist of evenly spaced square fingers that create a strong, visually distinct mechanical bond, suitable for box-making and easier to produce with power tools. Your choice depends on the required joint strength, aesthetic preference, and available tools, as dovetail joints offer enhanced durability while box joints are simpler and faster to cut.

Strength Comparison: Dovetail vs Box Joint

Dovetail joints offer superior tensile and shear strength compared to box joints, thanks to their interlocking, fan-shaped pins and tails that resist pulling apart under stress. Box joints provide good strength for right-angle connections but lack the mechanical locking of dovetails, making them less ideal for heavy-load applications. Your choice between these joints should consider the specific strength requirements and aesthetic preferences of your woodworking project.

Aesthetic Appeal and Design Considerations

Dovetail joints offer a distinctive, interlocking aesthetic prized in fine woodworking for their elegant, fan-shaped tails that enhance the visual appeal of drawers and cabinets. Box joints, with their evenly spaced square fingers, provide a clean, modern look that complements contemporary furniture design and offers strong corner reinforcement. Your choice between dovetail and box joints will depend on whether you prioritize traditional craftsmanship and intricate detailing or simplicity and geometric precision in your project.

Applications and Common Uses

Dovetail joints are predominantly used in high-quality cabinetry and fine furniture due to their superior tensile strength and decorative appearance, making them ideal for drawer construction and box corners. Box joints find common applications in mass-produced wooden crates, storage boxes, and simple furniture pieces where ease of manufacture and mechanical strength are prioritized over aesthetic detail. Both joints provide durable corner connections but cater to different design requirements and production scales.

Tools and Skills Required for Each Joint

Dovetail joints require precision tools such as a dovetail saw, chisels, and marking gauges, along with advanced woodworking skills to achieve tight, interlocking pins and tails. Box joints can be made using simpler tools like a table saw or router with a box joint jig, making them more accessible for intermediate woodworkers. Your choice depends on your comfort level with hand tools or power tools and the complexity of the project.

Pros and Cons of Dovetail Joints

Dovetail joints offer exceptional tensile strength and durability, making them ideal for drawer construction and fine woodworking where longevity and resistance to pulling forces are crucial. They provide superior aesthetic appeal due to their intricate, interlocking design, yet require precise cutting and skilled craftsmanship, which can increase production time and cost. Your decision to use dovetail joints should weigh these benefits against the complexity and time investment compared to simpler joints like box joints.

Pros and Cons of Box Joints

Box joints offer strong mechanical interlocking with increased gluing surface, making them ideal for box construction and furniture with high stress points. They are easier and faster to cut compared to dovetail joints, using simple jigs and routers, but lack the aesthetic appeal and traditional craftsmanship associated with dovetails. Your choice depends on balancing strength, production speed, and visual preference for woodworking projects.

Dovetail joint vs Box joint Infographic

libmatt.com

libmatt.com