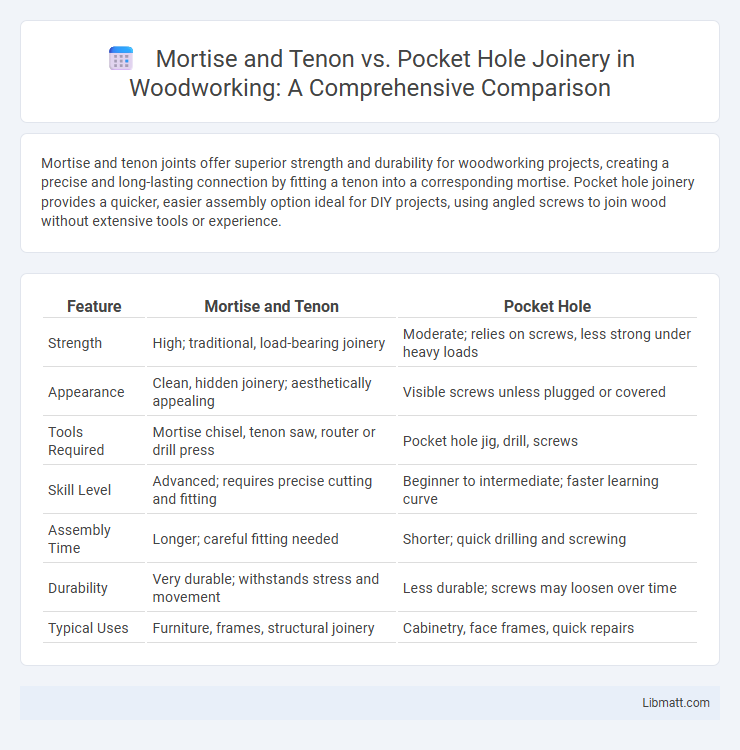

Mortise and tenon joints offer superior strength and durability for woodworking projects, creating a precise and long-lasting connection by fitting a tenon into a corresponding mortise. Pocket hole joinery provides a quicker, easier assembly option ideal for DIY projects, using angled screws to join wood without extensive tools or experience.

Table of Comparison

| Feature | Mortise and Tenon | Pocket Hole |

|---|---|---|

| Strength | High; traditional, load-bearing joinery | Moderate; relies on screws, less strong under heavy loads |

| Appearance | Clean, hidden joinery; aesthetically appealing | Visible screws unless plugged or covered |

| Tools Required | Mortise chisel, tenon saw, router or drill press | Pocket hole jig, drill, screws |

| Skill Level | Advanced; requires precise cutting and fitting | Beginner to intermediate; faster learning curve |

| Assembly Time | Longer; careful fitting needed | Shorter; quick drilling and screwing |

| Durability | Very durable; withstands stress and movement | Less durable; screws may loosen over time |

| Typical Uses | Furniture, frames, structural joinery | Cabinetry, face frames, quick repairs |

Introduction to Mortise and Tenon vs Pocket Hole Joints

Mortise and tenon joints offer unmatched strength and durability by fitting a tenon into a precisely cut mortise, making them ideal for traditional woodworking and high-stress applications. Pocket hole joints rely on angled screws to join boards quickly and easily, providing a faster, more accessible option for DIY projects and less visible fastening. Your choice between mortise and tenon versus pocket hole joints depends on the balance between long-term structural integrity and ease of assembly.

Overview of Mortise and Tenon Joinery

Mortise and tenon joinery is a traditional woodworking technique widely valued for its strength and durability, involving a rectangular peg (tenon) fitting precisely into a cavity (mortise) cut into another piece. This method creates a tight mechanical joint that can be reinforced with glue, making it ideal for structural applications in furniture and timber framing. Compared to pocket hole joinery, mortise and tenon offers superior load-bearing capabilities and longevity, often preferred in heirloom-quality craftsmanship.

Overview of Pocket Hole Joinery

Pocket hole joinery involves drilling a hole at an angle into one workpiece and joining it to another with a self-tapping screw, creating a strong, quick, and easily assembled joint ideal for DIY projects and furniture repair. This technique requires pocket hole jigs and specialized drill bits, allowing for concealed fasteners and minimizing the need for clamps during assembly. Compared to traditional mortise and tenon joints, pocket hole joinery offers faster construction with less precision but may sacrifice some long-term durability and aesthetic appeal.

Strength Comparison: Mortise and Tenon vs Pocket Hole

Mortise and tenon joints provide superior structural strength by creating a large glued surface area and interlocking components that resist shear and tensile forces effectively. Pocket hole joints rely on screws and angled holes, offering quicker assembly but less load-bearing capacity and durability under stress. For projects requiring long-term stability and robust load resistance, mortise and tenon joints are typically the stronger choice compared to pocket holes.

Tools and Equipment Needed for Each Method

Mortise and tenon joinery requires specialized tools such as chisels, mallets, mortise machines, and tenon saws to create precise interlocking joints that ensure strength and durability. Pocket hole joinery relies on a pocket hole jig, drill with a special pocket hole bit, and screws, allowing for quicker and easier assembly without the need for complex cutting tools. Both methods demand specific equipment tailored to their unique joint construction, influencing efficiency and final joint quality.

Ease of Assembly: Which is Simpler?

Mortise and tenon joints require precise cutting and fitting, making assembly more complex and time-consuming. Pocket hole joinery involves drilling angled holes and using screws, offering a quicker and more straightforward assembly process. Your choice depends on whether you prioritize traditional strength or ease and speed of construction.

Applications and Ideal Uses for Each Joint

Mortise and tenon joints excel in furniture and heavy woodworking projects requiring exceptional strength and durability, such as tables, chairs, and door frames. Pocket hole joints are ideal for quick assembly tasks in cabinetry, face frames, and smaller projects where speed and ease of use are crucial. Your choice depends on the structural demands and the type of woodworking project, with mortise and tenon favored for long-term stability and pocket holes suited for efficient, less load-bearing connections.

Durability and Longevity in Woodworking Projects

Mortise and tenon joints offer superior durability and longevity in woodworking projects due to their interlocking design, which provides maximum strength and resistance to shear forces. Pocket hole joints rely on screws and are quicker to assemble but generally lack the structural integrity for long-term heavy loads. Choosing mortise and tenon ensures your furniture maintains stability and withstands wear over time, making it ideal for heirloom-quality pieces.

Cost Implications: Materials and Tools

Mortise and tenon joints require precise cutting tools and hardwood materials, often resulting in higher initial costs but superior durability for long-term projects. Pocket hole joinery uses specialized jigs and screws, which are more affordable upfront and faster to assemble but may compromise on strength over time. Your choice depends on balancing budget constraints with the desired longevity and structural integrity of your woodworking project.

Conclusion: Choosing the Right Joinery Method

Mortise and tenon joints offer superior strength and durability for traditional woodworking projects, making them ideal for furniture that needs long-lasting stability. Pocket hole joinery provides a faster, more accessible solution for DIY enthusiasts and repairs, especially when working with softer woods or when speed is essential. Your choice depends on project requirements, with mortise and tenon excelling in heavy-duty applications and pocket holes suited for quick assembly and less visible joints.

Mortise and tenon vs Pocket hole Infographic

libmatt.com

libmatt.com