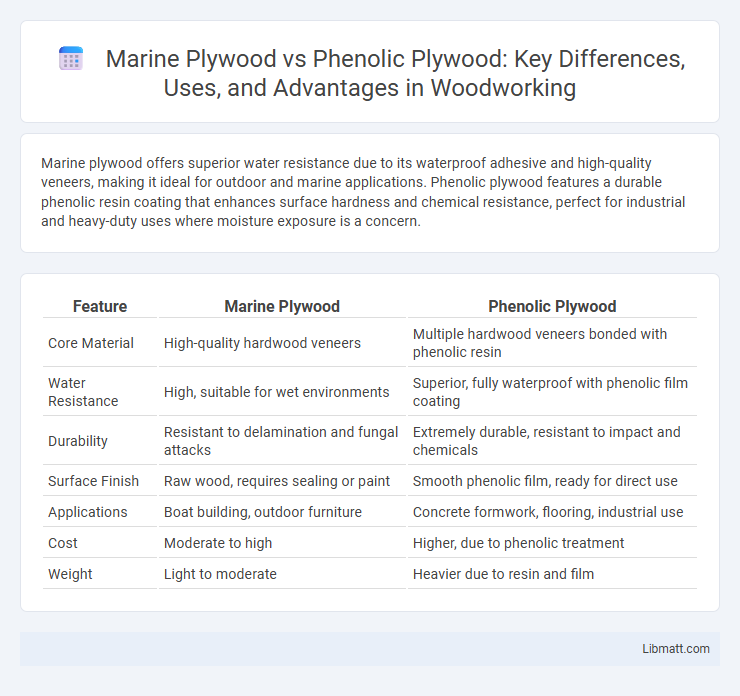

Marine plywood offers superior water resistance due to its waterproof adhesive and high-quality veneers, making it ideal for outdoor and marine applications. Phenolic plywood features a durable phenolic resin coating that enhances surface hardness and chemical resistance, perfect for industrial and heavy-duty uses where moisture exposure is a concern.

Table of Comparison

| Feature | Marine Plywood | Phenolic Plywood |

|---|---|---|

| Core Material | High-quality hardwood veneers | Multiple hardwood veneers bonded with phenolic resin |

| Water Resistance | High, suitable for wet environments | Superior, fully waterproof with phenolic film coating |

| Durability | Resistant to delamination and fungal attacks | Extremely durable, resistant to impact and chemicals |

| Surface Finish | Raw wood, requires sealing or paint | Smooth phenolic film, ready for direct use |

| Applications | Boat building, outdoor furniture | Concrete formwork, flooring, industrial use |

| Cost | Moderate to high | Higher, due to phenolic treatment |

| Weight | Light to moderate | Heavier due to resin and film |

Introduction to Marine Plywood and Phenolic Plywood

Marine plywood is a high-quality wood product designed for resistance to moisture and decay, commonly used in boat building and outdoor applications where durability is crucial. Phenolic plywood consists of plywood sheets coated with phenolic resin, enhancing water resistance, strength, and chemical durability, making it ideal for industrial flooring, countertops, and heavy-duty applications. Both types offer specific benefits in moisture resistance and structural integrity, with marine plywood emphasizing water-resistant glues and phenolic plywood providing a durable resin overlay.

Composition and Manufacturing Process

Marine plywood is crafted using durable hardwood veneers bonded with waterproof phenolic resin adhesives, ensuring high resistance to moisture and fungal attacks. Phenolic plywood features layers impregnated with phenolic resin, which enhances its strength, water resistance, and overall durability by providing a tough, laminated surface. Your choice depends on whether you need superior water resistance and structural integrity for marine environments or a versatile, high-strength plywood with a protective resin coating.

Physical Properties Comparison

Marine plywood features superior water resistance due to its high-quality waterproof glue and void-free construction, making it highly durable in wet environments. Phenolic plywood is coated with phenolic resin, providing an additional protective layer that enhances its strength, chemical resistance, and smooth surface finish. Your choice depends on whether you prioritize long-term water exposure resilience (marine plywood) or enhanced surface durability and chemical resistance (phenolic plywood).

Water and Moisture Resistance

Marine plywood offers superior water and moisture resistance due to its void-free construction and use of waterproof adhesives, making it ideal for environments exposed to constant humidity or wet conditions. Phenolic plywood features a durable phenolic resin coating that enhances surface water resistance and protects against moisture penetration, extending the lifespan of the plywood in damp settings. Your choice depends on whether you need structural integrity with moisture resistance (marine plywood) or a highly water-repellent surface finish (phenolic plywood).

Strength and Durability

Marine plywood is crafted with waterproof glue and high-quality hardwood veneers, providing superior resistance to water, rot, and delamination, making it ideal for marine and outdoor applications requiring long-lasting strength. Phenolic plywood is coated with a phenolic resin overlay that enhances surface hardness, chemical resistance, and abrasion protection, delivering excellent durability in environments exposed to moisture and mechanical wear. While marine plywood offers robust structural integrity in wet conditions, phenolic plywood excels in applications demanding both durability and a smooth, resilient surface finish.

Applications and Common Uses

Marine plywood, known for its water-resistant adhesive and durability, is widely used in boat building, outdoor furniture, and construction projects exposed to high moisture environments. Phenolic plywood features a resin-impregnated surface coating that provides superior chemical resistance and wear durability, making it ideal for industrial flooring, concrete formwork, and heavy-duty outdoor applications. Both types serve specialized roles where moisture resistance and structural integrity are critical, but phenolic plywood excels in harsh chemical and abrasion-prone settings.

Cost and Availability

Marine plywood typically costs more than phenolic plywood due to its high-quality wood veneers and water-resistant adhesive, making it ideal for heavy-duty marine applications. Phenolic plywood, coated with a durable resin film, offers greater availability and affordability for general construction and outdoor projects. Choosing the right plywood depends on balancing your budget with the specific strength and moisture resistance requirements of your project.

Advantages of Marine Plywood

Marine plywood offers exceptional water resistance and durability due to its high-quality hardwood veneers and waterproof adhesive, making it ideal for outdoor and marine environments. Its resistance to fungal attacks and delamination ensures long-term structural integrity under constant exposure to moisture. The smooth surface and consistent thickness of marine plywood enhance its suitability for precision woodworking and finishing applications.

Benefits of Phenolic Plywood

Phenolic plywood offers exceptional durability and water resistance due to its resin-impregnated paper layers, making it ideal for harsh environments and heavy-duty applications. Its smooth, non-porous surface resists chemicals, abrasion, and UV exposure better than marine plywood, extending its lifespan in outdoor and industrial settings. The high strength-to-weight ratio and consistent quality of phenolic plywood provide superior structural performance in construction, transportation, and marine industries.

Choosing the Right Plywood for Your Project

Marine plywood offers superior water resistance and durability due to its waterproof glue and high-quality hardwood veneers, making it ideal for outdoor and water-exposed projects. Phenolic plywood features a resin-impregnated phenolic film coating, providing enhanced chemical resistance and a smooth, durable surface perfect for industrial applications and heavy-duty use. Selecting marine plywood or phenolic plywood depends on the project's exposure to moisture, chemical contact, and the need for surface durability.

Marine plywood vs phenolic plywood Infographic

libmatt.com

libmatt.com