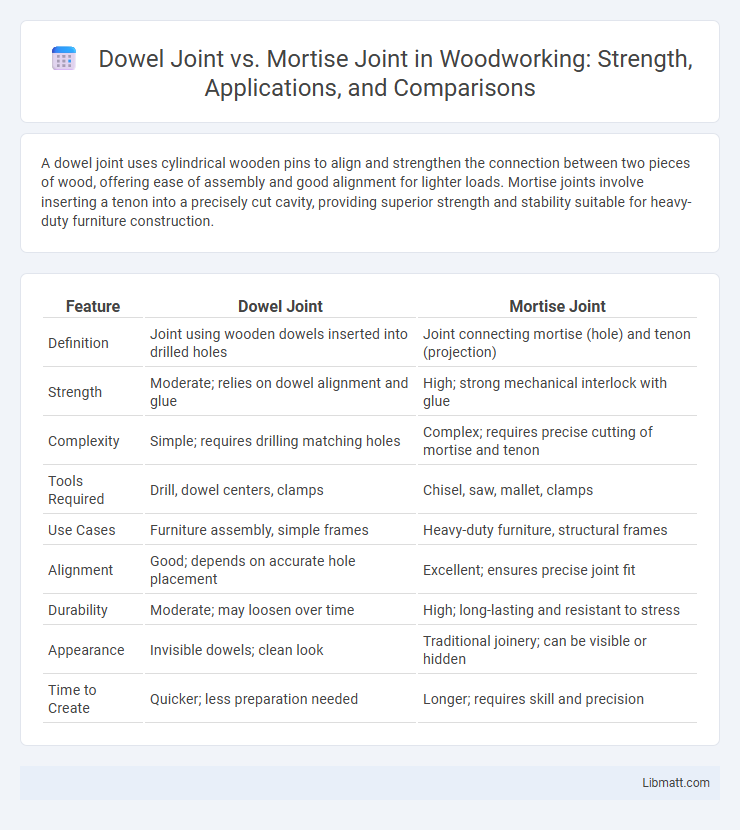

A dowel joint uses cylindrical wooden pins to align and strengthen the connection between two pieces of wood, offering ease of assembly and good alignment for lighter loads. Mortise joints involve inserting a tenon into a precisely cut cavity, providing superior strength and stability suitable for heavy-duty furniture construction.

Table of Comparison

| Feature | Dowel Joint | Mortise Joint |

|---|---|---|

| Definition | Joint using wooden dowels inserted into drilled holes | Joint connecting mortise (hole) and tenon (projection) |

| Strength | Moderate; relies on dowel alignment and glue | High; strong mechanical interlock with glue |

| Complexity | Simple; requires drilling matching holes | Complex; requires precise cutting of mortise and tenon |

| Tools Required | Drill, dowel centers, clamps | Chisel, saw, mallet, clamps |

| Use Cases | Furniture assembly, simple frames | Heavy-duty furniture, structural frames |

| Alignment | Good; depends on accurate hole placement | Excellent; ensures precise joint fit |

| Durability | Moderate; may loosen over time | High; long-lasting and resistant to stress |

| Appearance | Invisible dowels; clean look | Traditional joinery; can be visible or hidden |

| Time to Create | Quicker; less preparation needed | Longer; requires skill and precision |

Introduction to Wood Joinery Techniques

Dowel joints use cylindrical wooden pins to align and strengthen the connection, offering precise alignment and ease of assembly. Mortise joints involve a rectangular cavity (mortise) cut into one piece of wood, fitted with a corresponding tenon, delivering exceptional strength and durability for load-bearing furniture. Your choice between these wood joinery techniques depends on the desired strength, appearance, and application of the woodworking project.

What is a Dowel Joint?

A dowel joint is a woodworking technique that uses cylindrical wooden pins inserted into aligned holes in two adjoining pieces of wood to create a strong, precise connection. This joint offers enhanced alignment and stability compared to simple butt joints, making it ideal for furniture and cabinet construction. Understanding how a dowel joint works can help you achieve durable, seamless wood assemblies in your projects.

What is a Mortise and Tenon Joint?

A mortise and tenon joint consists of a rectangular hole (mortise) cut into one piece of wood, into which a corresponding projecting piece (tenon) on another piece fits securely. This joint provides exceptional strength and stability, making it ideal for load-bearing furniture and timber framing. Compared to dowel joints, mortise and tenon connections offer superior resistance to twisting and shear forces.

Strength and Durability Comparison

Dowel joints provide moderate strength due to the mechanical interlocking of dowels and wood fibers but may weaken over time if exposed to moisture or stress. Mortise joints, designed to fit precisely with tenons, offer superior durability and load-bearing capacity, making them ideal for high-stress applications and long-lasting furniture construction. Your choice between dowel and mortise joints should consider the specific strength requirements and environmental conditions of the project.

Ease of Construction and Assembly

Dowel joints offer greater ease of construction and assembly due to their straightforward drilling and alignment process using standardized dowel pins, which simplifies positioning and reduces the need for intricate tools. Mortise joints, although providing superior strength, require precise cutting of mortise cavities and tenons, demanding advanced woodworking skills and more time-intensive preparation. The dowel joint's simplicity makes it ideal for quick assembly and lower skill levels, whereas mortise joints are preferred when durability and structural integrity outweigh ease of construction.

Tools and Materials Required

Dowel joints require drill bits, dowel pins, clamps, and woodworking glue, often made from hardwood dowels to ensure strong connections. Mortise joints demand chisels, mortise machines or drills with mortising attachments, mallets, and precision measuring tools, typically involving hardwood or softwood materials for the mortise and tenon components. Choosing the right tools and materials for your woodworking project ensures accurate fitting and long-lasting joint strength.

Applications in Furniture and Woodworking

Dowel joints are widely used in furniture construction for aligning and reinforcing panels, making them ideal for assembling flat surfaces like tabletops and cabinet frames. Mortise joints provide superior strength and stability, commonly applied in load-bearing structures such as chair legs, door frames, and bed frames where durability is critical. Both joints optimize woodworking projects, but mortise joints are preferred for their resistance to shear forces and dowel joints for ease of assembly and alignment.

Cost and Time Efficiency

Dowel joints are generally more cost-effective and faster to assemble than mortise joints due to their simpler construction and fewer specialized tools required. Mortise joints, while offering superior strength and durability, demand more precise craftsmanship and longer cutting time, increasing both labor costs and project duration. Choosing dowel joints can help you save time and reduce expenses in woodworking projects without significantly compromising joint integrity.

Aesthetic Considerations in Joint Selection

Dowel joints offer a cleaner, more seamless appearance due to their hidden fasteners, making them ideal for furniture where visual appeal is crucial. Mortise joints, while slightly more visible, provide a classic, handcrafted look that enhances the aesthetic value of traditional woodworking. Your choice between dowel and mortise joints should balance the desired visual effect with the overall design style of the project.

Final Verdict: Choosing the Right Joint for Your Project

Dowel joints offer strong alignment and ease of assembly, making them ideal for lightweight furniture and quick projects. Mortise joints provide superior strength and durability, suitable for heavy-duty constructions requiring long-lasting stability. Selecting the right joint depends on the specific structural demands and the desired balance between assembly speed and joint robustness.

Dowel joint vs Mortise joint Infographic

libmatt.com

libmatt.com