Doweled joints rely on cylindrical wooden pins to align and strengthen joint connections, offering easier assembly and alignment compared to the more traditional mortise and tenon joint. Mortise and tenon joints provide superior strength and durability, making them ideal for load-bearing structures and long-lasting woodworking projects where Your furniture's longevity is a priority.

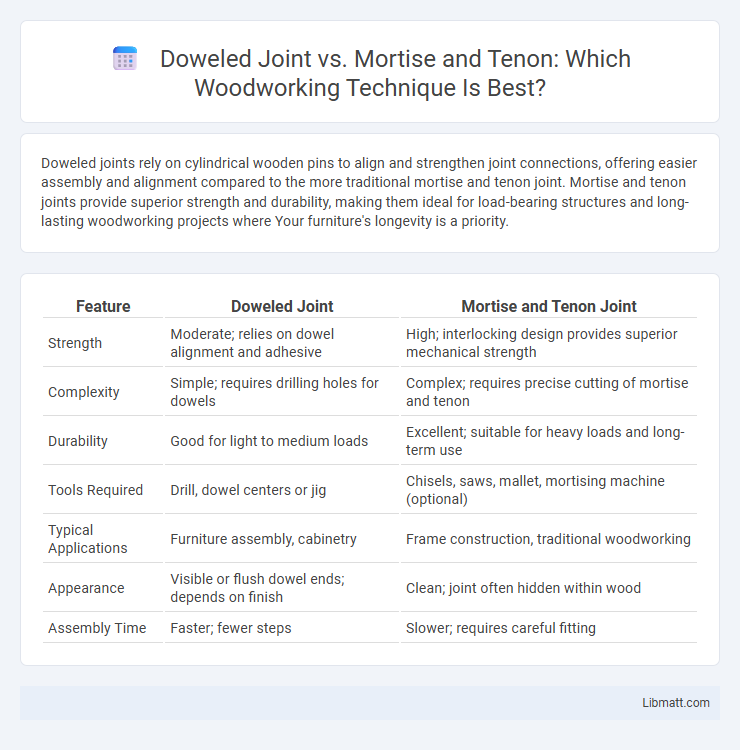

Table of Comparison

| Feature | Doweled Joint | Mortise and Tenon Joint |

|---|---|---|

| Strength | Moderate; relies on dowel alignment and adhesive | High; interlocking design provides superior mechanical strength |

| Complexity | Simple; requires drilling holes for dowels | Complex; requires precise cutting of mortise and tenon |

| Durability | Good for light to medium loads | Excellent; suitable for heavy loads and long-term use |

| Tools Required | Drill, dowel centers or jig | Chisels, saws, mallet, mortising machine (optional) |

| Typical Applications | Furniture assembly, cabinetry | Frame construction, traditional woodworking |

| Appearance | Visible or flush dowel ends; depends on finish | Clean; joint often hidden within wood |

| Assembly Time | Faster; fewer steps | Slower; requires careful fitting |

Introduction to Doweled Joints and Mortise and Tenon

Doweled joints utilize cylindrical wooden pins inserted into aligned holes in two adjoining wood pieces, providing alignment and moderate strength primarily in cabinet and furniture construction. Mortise and tenon joints consist of a protruding tenon on one piece that fits precisely into a rectangular mortise hole on another, offering superior structural integrity and resistance to shear forces, commonly used in timber framing and high-quality woodworking. Both joint types serve as fundamental techniques for mechanical fastening in woodworking, with doweled joints favoring ease of assembly and mortise and tenon joints excelling in durability and load-bearing capacity.

Historical Background and Applications

Doweled joints date back to ancient Egyptian and Roman woodworking, widely used for rigid frame assemblies where quick, repeatable manufacturing was essential. Mortise and tenon joints have a history stretching over 5,000 years, prominent in traditional timber framing and furniture due to their strength and long-lasting durability. Modern applications favor doweled joints in mass-produced cabinetry and furniture for efficiency, while mortise and tenon remain preferred in high-quality, handcrafted woodwork requiring superior load-bearing capacity.

Construction Techniques Explained

Doweled joints utilize cylindrical wooden pins inserted into aligned holes on adjoining pieces, providing moderate strength and ease of assembly ideal for cabinetry and furniture frames. Mortise and tenon joints consist of a protruding tenon fitting precisely into a mortise cavity, creating a robust mechanical interlock favored in traditional woodworking and structural applications. Both methods rely on precise alignment and secure adhesion, with mortise and tenon joints offering superior durability in load-bearing constructions.

Material Compatibility and Selection

Doweled joints are ideal for lightweight materials like softwoods and engineered wood, where precision drills and dowel sizes match the material's density for secure bonding. Mortise and tenon joints excel with hardwoods due to their ability to withstand greater stress and provide long-lasting structural integrity in heavy-duty applications. Your choice depends on material hardness and the desired strength; doweled joints suit softer woods and quick assembly, while mortise and tenon are preferred for durable, load-bearing hardwood structures.

Strength and Durability Comparison

Doweled joints offer moderate strength, mainly suitable for light to medium load applications, but their durability can be compromised under prolonged stress or moisture exposure. Mortise and tenon joints provide superior strength and durability due to their large gluing surface and mechanical interlocking, making them ideal for heavy-duty furniture and structural woodwork. Your choice should consider the joint's intended load-bearing requirements and exposure conditions to ensure long-lasting performance.

Aesthetic Considerations

Doweled joints provide a cleaner, more streamlined appearance due to the hidden dowels, making them ideal for modern or minimalist furniture designs. Mortise and tenon joints, often visible in traditional woodworking, showcase craftsmanship and add a classic, rustic charm to pieces. The choice between doweled and mortise and tenon joints significantly impacts the overall aesthetic, with dowels favoring sleek looks and mortise and tenon highlighting artisanal detail.

Tools and Skill Requirements

Doweled joints require basic tools such as a drill, dowel jig, and clamps, making them accessible for beginners with moderate woodworking experience. Mortise and tenon joints demand advanced skills and specialized tools like mortising machines or chisels for precise cuts, challenging even skilled woodworkers. Your choice depends on the complexity of the project and the tools and skills you possess.

Cost and Time Efficiency

Doweled joints are generally more cost-effective and quicker to produce due to simpler tools and less skilled labor required, making them ideal for mass production and DIY projects. Mortise and tenon joints demand precise craftsmanship and additional time, increasing labor costs but offering superior strength and durability for high-quality, long-lasting furniture. Your choice depends on prioritizing budget and speed versus long-term structural integrity.

Common Uses in Furniture and Woodworking

Doweled joints are commonly used in lightweight furniture and quick assembly projects due to their ease of alignment and moderate strength, making them ideal for cabinetry and flat-pack furniture. Mortise and tenon joints are preferred in high-quality woodworking for structural frames, chairs, and tables because of their superior strength and durability. Your choice between these joints depends on the balance between ease of construction and the load-bearing requirements of the piece.

Choosing the Best Joint for Your Project

Doweled joints provide quick alignment and moderate strength, ideal for furniture requiring efficient assembly and a clean appearance, while mortise and tenon joints offer superior durability and load-bearing capacity, making them preferred for structural or heirloom pieces. Evaluating project requirements such as load, aesthetics, and woodworking skill helps determine the optimal choice; doweled joints suit mass production and ease of assembly, whereas mortise and tenon joints serve projects demanding long-term resilience and traditional craftsmanship. Material type and expected stress also influence the selection, as hardwoods complement mortise and tenon joints, contrasting with the versatility and speed of doweled joints in various wood types.

Doweled joint vs mortise and tenon Infographic

libmatt.com

libmatt.com