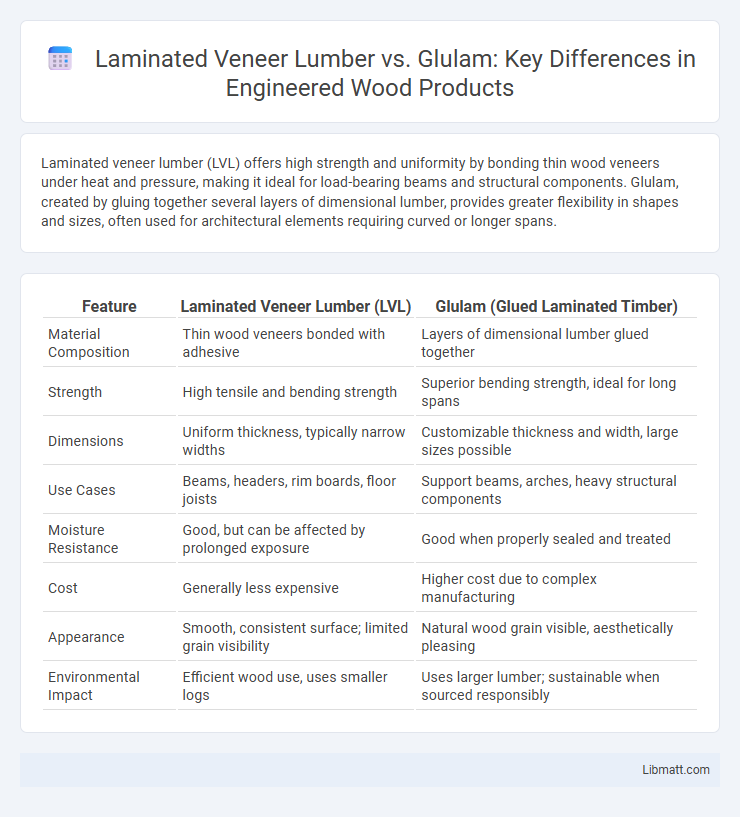

Laminated veneer lumber (LVL) offers high strength and uniformity by bonding thin wood veneers under heat and pressure, making it ideal for load-bearing beams and structural components. Glulam, created by gluing together several layers of dimensional lumber, provides greater flexibility in shapes and sizes, often used for architectural elements requiring curved or longer spans.

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Glulam (Glued Laminated Timber) |

|---|---|---|

| Material Composition | Thin wood veneers bonded with adhesive | Layers of dimensional lumber glued together |

| Strength | High tensile and bending strength | Superior bending strength, ideal for long spans |

| Dimensions | Uniform thickness, typically narrow widths | Customizable thickness and width, large sizes possible |

| Use Cases | Beams, headers, rim boards, floor joists | Support beams, arches, heavy structural components |

| Moisture Resistance | Good, but can be affected by prolonged exposure | Good when properly sealed and treated |

| Cost | Generally less expensive | Higher cost due to complex manufacturing |

| Appearance | Smooth, consistent surface; limited grain visibility | Natural wood grain visible, aesthetically pleasing |

| Environmental Impact | Efficient wood use, uses smaller logs | Uses larger lumber; sustainable when sourced responsibly |

Introduction to Laminated Veneer Lumber and Glulam

Laminated Veneer Lumber (LVL) and Glued Laminated Timber (Glulam) are engineered wood products designed for structural applications, offering high strength and dimensional stability. LVL is made from thin wood veneers aligned and bonded under heat and pressure, creating a uniform, dense material ideal for beams and headers. Glulam consists of multiple layers of solid wood laminations glued together, allowing for curved and straight structural elements that can span long distances and support heavy loads in construction projects.

Manufacturing Processes Compared

Laminated veneer lumber (LVL) is produced by bonding thin wood veneers together under heat and pressure, aligning the grains for consistent strength and stability. Glulam is manufactured by gluing together multiple layers of solid wood laminations with the grains oriented parallel, often using larger boards compared to LVL veneers. Both processes emphasize precise adhesive application and curing, but LVL allows for more uniformity due to veneer-scale layering, while glulam capitalizes on the natural characteristics of solid timber laminations.

Material Composition and Structure

Laminated veneer lumber (LVL) is composed of thin wood veneers bonded together under heat and pressure, oriented with the grain parallel to enhance strength and stiffness. Glulam consists of multiple layers of solid dimensional lumber bonded with durable adhesives, often allowing curved or straight configurations for versatile architectural applications. Your choice between LVL and glulam depends on the specific load requirements and design flexibility needed for your construction project.

Strength and Load-Bearing Capabilities

Laminated veneer lumber (LVL) exhibits consistent strength and high stiffness due to its thin wood veneers glued under heat and pressure, making it ideal for heavy load-bearing applications like beams and headers. Glulam beams, made by bonding together multiple layers of dimensional lumber, offer superior load-bearing capacity and flexural strength, suitable for long spans and complex architectural designs. Your choice between LVL and glulam should consider the specific structural requirements, where LVL provides uniform strength and glulam excels in larger, curved, or aesthetic applications.

Applications in Construction

Laminated veneer lumber (LVL) is widely used in residential and commercial framing applications such as beams, headers, and rim boards due to its high strength-to-weight ratio and uniformity. Glulam (glue-laminated timber) is favored in large-scale structural projects including bridges, post-and-beam buildings, and long-span roof systems because of its ability to support heavy loads and create architectural shapes. Your choice between LVL and glulam depends on load requirements, span length, and aesthetic preferences in construction design.

Durability and Resistance to Environmental Factors

Laminated veneer lumber (LVL) and glulam both offer excellent durability, with LVL providing superior dimensional stability due to its thin veneer layers bonded under heat and pressure, reducing susceptibility to warping and twisting. Glulam's thick glued timber layers resist heavy loads and perform well in moisture-rich environments, but require proper sealing to prevent decay and insect damage. For your construction project, LVL is often preferred in applications requiring higher resistance to environmental fluctuations, while glulam excels in structural elements exposed to moderate environmental stress.

Sustainability and Environmental Impact

Laminated veneer lumber (LVL) and glulam both offer sustainable alternatives to traditional solid wood, with LVL utilizing thin wood veneers bonded together to maximize resource efficiency and reduce waste. Glulam, composed of multiple layers of dimensional lumber glued to form large structural elements, often uses fast-growing, sustainably harvested softwoods, minimizing forest depletion. Your choice between LVL and glulam can influence your project's carbon footprint, as both materials provide strong, durable solutions that support responsible forestry and long-term environmental benefits.

Cost Comparison and Economic Considerations

Laminated veneer lumber (LVL) generally costs less per unit than glulam due to its efficient manufacturing process using thin wood veneers, making it a budget-friendly option for large-scale projects. Glulam offers greater design flexibility and higher load-bearing capacity, which can justify its higher price in applications requiring complex structural elements or longer spans. Your choice between LVL and glulam should consider both upfront material costs and long-term economic benefits related to project requirements and structural performance.

Design Flexibility and Architectural Usage

Laminated veneer lumber (LVL) offers superior design flexibility due to its uniform strength and ability to be manufactured in long, continuous lengths, making it ideal for precise architectural applications like beams and headers. Glulam, composed of multiple layers of solid wood bonded with durable adhesives, provides aesthetic appeal with visible wood grain and can be fabricated into curved or complex shapes, enhancing architectural creativity. Your choice between LVL and glulam will depend on the specific structural requirements and desired visual impact of your building project.

Choosing Between Laminated Veneer Lumber and Glulam

Choosing between laminated veneer lumber (LVL) and glulam depends on your project's structural requirements and design preferences. LVL offers high strength and uniformity due to its thin wood veneers glued under heat and pressure, making it ideal for long, straight spans with consistent load-bearing needs. Glulam, composed of multiple layers of dimensional lumber bonded together, provides greater flexibility in shapes and aesthetic appeal, suitable for curved beams and architectural elements requiring both strength and visual impact.

Laminated veneer lumber vs glulam Infographic

libmatt.com

libmatt.com