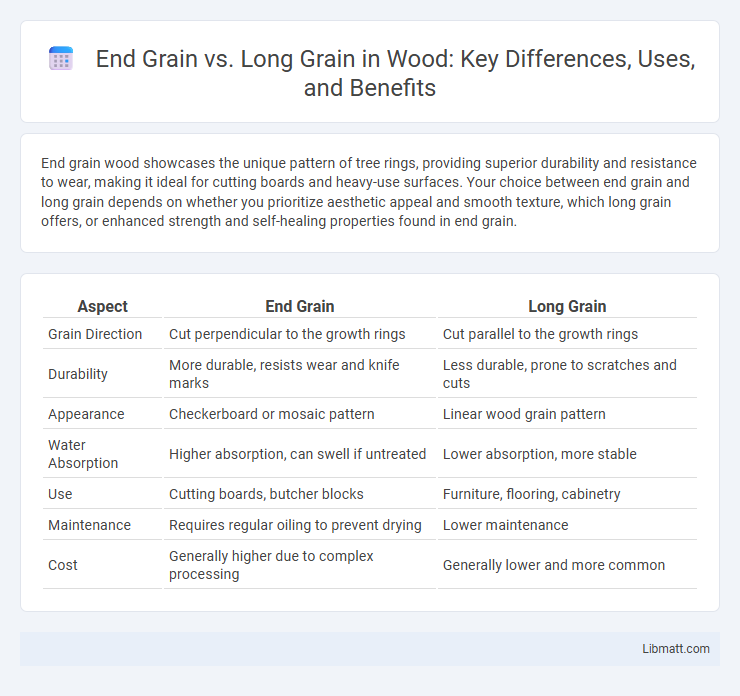

End grain wood showcases the unique pattern of tree rings, providing superior durability and resistance to wear, making it ideal for cutting boards and heavy-use surfaces. Your choice between end grain and long grain depends on whether you prioritize aesthetic appeal and smooth texture, which long grain offers, or enhanced strength and self-healing properties found in end grain.

Table of Comparison

| Aspect | End Grain | Long Grain |

|---|---|---|

| Grain Direction | Cut perpendicular to the growth rings | Cut parallel to the growth rings |

| Durability | More durable, resists wear and knife marks | Less durable, prone to scratches and cuts |

| Appearance | Checkerboard or mosaic pattern | Linear wood grain pattern |

| Water Absorption | Higher absorption, can swell if untreated | Lower absorption, more stable |

| Use | Cutting boards, butcher blocks | Furniture, flooring, cabinetry |

| Maintenance | Requires regular oiling to prevent drying | Lower maintenance |

| Cost | Generally higher due to complex processing | Generally lower and more common |

Understanding End Grain and Long Grain

End grain refers to cutting wood perpendicular to the growth rings, revealing the wood's cross-section, which offers superior durability and resistance to knife marks, making it ideal for cutting boards. Long grain, cut parallel to the growth rings, displays the wood's lengthwise fibers and provides a smoother, visually appealing surface that is often easier to clean. Understanding the differences between end grain and long grain helps you choose the right material for your kitchen tools or woodworking projects based on durability and aesthetics.

Key Differences Between End Grain and Long Grain

End grain wood showcases the growth rings as circular patterns, providing superior durability and resistance to knife marks, making it ideal for heavy chopping boards. Long grain wood displays elongated, parallel wood fibers, offering a smoother surface that is easier to clean but more prone to wear and scratches. End grain boards tend to self-heal from cuts, while long grain boards maintain a sleek appearance but require more maintenance to prevent damage.

Durability and Longevity Comparison

End grain cutting boards absorb knife impacts better, resulting in less blade dulling and enhanced durability compared to long grain boards, which show wear more quickly due to the alignment of wood fibers. Your choice of an end grain board supports longer-lasting performance and maintains a smoother surface over time, making it ideal for heavy, frequent use. Long grain boards offer a sturdy option but may require more maintenance and replacement to achieve the same longevity.

Surface Maintenance and Care

End grain cutting boards are more resilient to knife scratches and tend to self-heal over time, making surface maintenance easier with regular oiling and gentle cleaning. Long grain boards show knife marks more visibly and may require more frequent sanding to maintain a smooth surface. You can prolong the lifespan of both types by avoiding excessive moisture and using mineral oil or specialized board conditioners consistently.

Cutting Performance: Sharpness and Knife Preservation

End grain cutting boards enhance cutting performance by allowing knife blades to penetrate the wood fibers, preserving sharpness longer and reducing wear on your knives. Long grain boards, while durable, cause more blade resistance and quicker dulling due to the knife slicing across wood fibers. Choosing end grain boards supports better sharpness maintenance and extends the lifespan of both blades and cutting surfaces.

Aesthetic Appeal and Design Choices

End grain wood showcases intricate, unique patterns of growth rings, providing a rich, textured aesthetic highly sought after in premium furniture and cutting boards. Long grain wood offers a more uniform, linear appearance that enhances contemporary design with clean lines and consistent coloration. Designers often select end grain for statement pieces emphasizing natural beauty, while long grain suits minimalist and sleek styles prioritizing simplicity and durability.

Hygiene and Food Safety Considerations

End grain cutting boards are more hygienic than long grain boards because their fibrous surface better resists deep cuts and bacteria buildup, which minimizes contamination risks. Long grain boards develop grooves more quickly, providing hiding spots for bacteria and making thorough cleaning difficult. Choosing an end grain cutting board enhances your food safety by reducing the chance of cross-contamination and maintaining a more sanitary prep surface.

Cost and Investment Value

End grain cutting boards typically have a higher initial cost compared to long grain boards due to the labor-intensive process and the durability offered by the end grain orientation. Your investment in an end grain board pays off with superior knife retention and repairability, often extending the board's lifespan significantly longer than long grain options. Long grain boards are generally more affordable but may require more frequent replacement, impacting long-term cost-effectiveness.

Best Uses for End Grain and Long Grain Boards

End grain cutting boards excel in durability and knife preservation, making them ideal for heavy chopping, slicing, and dicing tasks in your kitchen. Long grain boards, with their smooth surface and attractive wood pattern, are best suited for serving, presentation, and light cutting activities. Choosing the right board depends on whether you prioritize cutting performance or aesthetic appeal.

Choosing the Right Grain Type for Your Needs

End grain and long grain cutting boards offer distinct advantages depending on your culinary needs. End grain boards are highly durable and gentle on knives, making them ideal for frequent chopping and heavy-duty use, while long grain boards provide a smooth surface better suited for slicing and serving. Understanding your kitchen tasks will help you choose the right grain type that enhances your cooking experience and preserves your knife's sharpness.

End grain vs Long grain Infographic

libmatt.com

libmatt.com