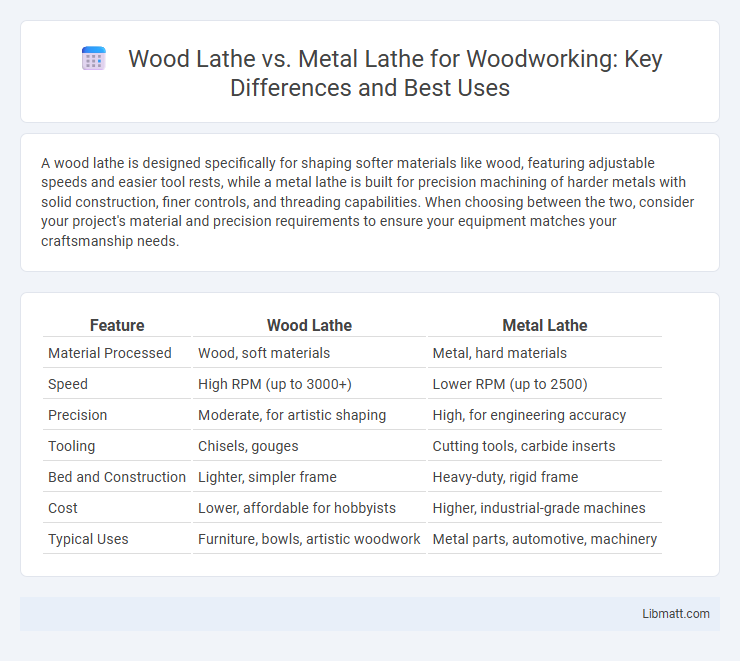

A wood lathe is designed specifically for shaping softer materials like wood, featuring adjustable speeds and easier tool rests, while a metal lathe is built for precision machining of harder metals with solid construction, finer controls, and threading capabilities. When choosing between the two, consider your project's material and precision requirements to ensure your equipment matches your craftsmanship needs.

Table of Comparison

| Feature | Wood Lathe | Metal Lathe |

|---|---|---|

| Material Processed | Wood, soft materials | Metal, hard materials |

| Speed | High RPM (up to 3000+) | Lower RPM (up to 2500) |

| Precision | Moderate, for artistic shaping | High, for engineering accuracy |

| Tooling | Chisels, gouges | Cutting tools, carbide inserts |

| Bed and Construction | Lighter, simpler frame | Heavy-duty, rigid frame |

| Cost | Lower, affordable for hobbyists | Higher, industrial-grade machines |

| Typical Uses | Furniture, bowls, artistic woodwork | Metal parts, automotive, machinery |

Introduction to Wood Lathes and Metal Lathes

Wood lathes are designed for shaping softer materials like wood by rotating the workpiece against various cutting tools, emphasizing simplicity and versatility for craft and furniture making. Metal lathes offer precision engineering for machining hard metals, featuring robust construction and higher RPM capabilities to create intricate parts and components. Both tools serve distinct purposes, with wood lathes focusing on artistic woodturning and metal lathes specializing in high-precision metalworking tasks.

Core Differences Between Wood Lathes and Metal Lathes

Wood lathes are designed for shaping softer materials like wood, featuring simpler construction and higher speed settings to accommodate the nature of woodturning. Metal lathes, built with robust precision, handle harder materials such as metals, offering greater rigidity, slower speeds, and advanced features like threading capabilities and fine feed controls. Your choice depends on the material you intend to work with, as each lathe type is optimized for specific machining requirements and tolerances.

Materials Each Lathe is Designed to Handle

Wood lathes are specifically engineered to work with softer materials like wood, offering lower speed ranges and tool rest designs optimized for shaping, sanding, and carving timber. Metal lathes handle harder materials such as steel, aluminum, and brass, featuring robust construction, precise control, and higher speed capabilities to accommodate cutting, threading, and drilling metal parts. Choosing the right lathe depends on Your material workpiece, as wood lathes excel with organic, softer substrates, while metal lathes provide the rigidity and power needed for machining dense or metallic components.

Key Components and Mechanisms

Wood lathes typically include a headstock, tailstock, tool rest, and bed, designed for shaping softer materials with tools stabilized on the tool rest. Metal lathes feature a more complex carriage system, including a cross-slide and compound rest, allowing precise control for cutting harder metals. Understanding the key components of each lathe helps you select the right machine based on the material and precision required for your project.

Precision and Versatility Comparison

Wood lathes offer high versatility for shaping softer materials with less precision, making them ideal for artistic and decorative projects. Metal lathes provide superior precision and rigidity, capable of machining harder metals with tight tolerances for engineering and manufacturing applications. The choice between wood and metal lathes depends on the required accuracy and material hardness in your project.

Common Applications for Wood and Metal Lathes

Wood lathes are commonly used for crafting furniture components, decorative bowls, and intricate wooden sculptures, highlighting their precision in shaping softer materials. Metal lathes excel in machining engine parts, fasteners, and custom metal components, providing high accuracy in cutting harder metals. Both tools are essential in manufacturing and prototyping, with their applications driven by the material type and desired finish quality.

Safety Considerations and Best Practices

Wood lathes require strict adherence to safety measures such as wearing face shields and avoiding loose clothing to prevent wood chips from causing injury, while metal lathes demand the use of protective gloves and eye protection due to high-speed metal shavings and coolant splashes. Proper clamping, regular maintenance of cutting tools, and ensuring the workpiece is securely fastened are critical safety practices for both types of lathes to prevent accidents. Understanding material-specific hazards and adopting machine-specific safety protocols reduce the risk of injury and improve operational efficiency.

Cost and Maintenance Factors

Wood lathes generally have a lower purchase price and reduced maintenance costs compared to metal lathes, making them more accessible for hobbyists and small workshops. Metal lathes require more precise components and regular lubrication, increasing both initial investment and upkeep expenses. The durability and complexity of metal lathes often lead to higher long-term maintenance costs due to specialized parts and calibration needs.

Choosing the Right Lathe for Your Needs

Wood lathes excel in shaping softer materials with simpler tooling and higher spindle speeds, making them ideal for crafting furniture or decorative items. Metal lathes offer precision machining for harder metals, with advanced features like threading and taper turning, suited for engineering and manufacturing applications. Evaluate the materials, project complexity, and required accuracy to choose the right lathe for your needs, ensuring efficient and high-quality results.

Conclusion: Which Lathe Is Right for You?

Choosing between a wood lathe and a metal lathe depends on the material you plan to work with and the precision you require. Wood lathes excel in shaping softer materials with ease and are ideal for hobbyists or woodworking projects, while metal lathes offer greater accuracy and versatility for machining harder metals and complex tasks. Your decision should align with your specific project needs, budget, and the level of detail you want to achieve.

Wood lathe vs Metal lathe Infographic

libmatt.com

libmatt.com