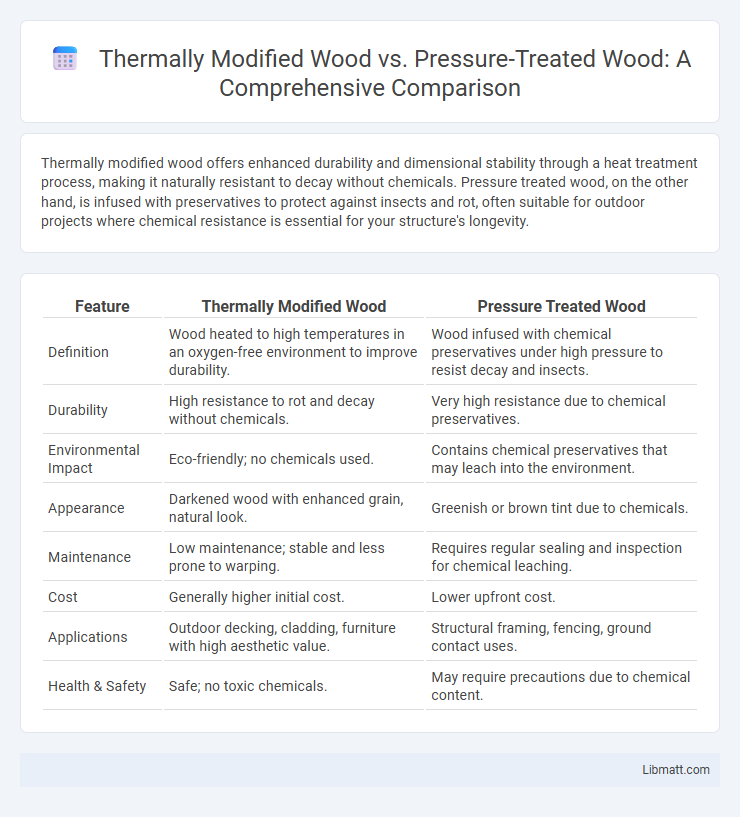

Thermally modified wood offers enhanced durability and dimensional stability through a heat treatment process, making it naturally resistant to decay without chemicals. Pressure treated wood, on the other hand, is infused with preservatives to protect against insects and rot, often suitable for outdoor projects where chemical resistance is essential for your structure's longevity.

Table of Comparison

| Feature | Thermally Modified Wood | Pressure Treated Wood |

|---|---|---|

| Definition | Wood heated to high temperatures in an oxygen-free environment to improve durability. | Wood infused with chemical preservatives under high pressure to resist decay and insects. |

| Durability | High resistance to rot and decay without chemicals. | Very high resistance due to chemical preservatives. |

| Environmental Impact | Eco-friendly; no chemicals used. | Contains chemical preservatives that may leach into the environment. |

| Appearance | Darkened wood with enhanced grain, natural look. | Greenish or brown tint due to chemicals. |

| Maintenance | Low maintenance; stable and less prone to warping. | Requires regular sealing and inspection for chemical leaching. |

| Cost | Generally higher initial cost. | Lower upfront cost. |

| Applications | Outdoor decking, cladding, furniture with high aesthetic value. | Structural framing, fencing, ground contact uses. |

| Health & Safety | Safe; no toxic chemicals. | May require precautions due to chemical content. |

Introduction to Thermally Modified Wood and Pressure Treated Wood

Thermally modified wood undergoes a heat treatment process at high temperatures, enhancing its durability, stability, and resistance to decay without the use of chemicals. Pressure treated wood is infused with chemical preservatives under high pressure to protect against rot, insects, and fungal decay, commonly used in outdoor applications. Both materials offer improved longevity, but thermally modified wood is favored for its environmentally friendly and chemical-free treatment method.

Process Overview: Thermal Modification vs Pressure Treatment

Thermally modified wood undergoes a heat treatment process where wood is exposed to high temperatures (160-230degC) in a low-oxygen environment, altering its chemical structure to enhance durability and resistance to decay without adding chemicals. Pressure treated wood involves forcing chemical preservatives deep into the wood fibers under high pressure, providing protection against insects, fungi, and moisture. Your choice depends on whether you prefer a more natural, chemical-free modification with thermal treatment or a chemically preserved option with pressure treatment for long-lasting protection.

Key Differences in Chemical Treatment and Additives

Thermally modified wood undergoes a high-temperature treatment that alters its chemical structure by reducing hemicellulose content, enhancing durability and dimensional stability without harmful chemicals. Pressure treated wood is infused with chemical preservatives like copper-based compounds to protect against decay and insect damage, relying on additives rather than heat for protection. The chemical treatment in thermally modified wood is environmentally friendly and chemical-free, whereas pressure treated wood contains synthetic biocides that can pose environmental and health risks.

Durability and Resistance to Decay

Thermally modified wood undergoes a heat treatment process that enhances its durability by reducing moisture absorption and increasing resistance to fungal decay and insect attacks without chemicals. Pressure treated wood is infused with chemical preservatives such as copper compounds, providing strong protection against rot, decay, and termites, especially in ground contact applications. While pressure treated wood offers higher protection for exterior structural use, thermally modified wood presents a more environmentally friendly option with improved dimensional stability and moderate decay resistance for decking and cladding.

Environmental Impact and Sustainability

Thermally modified wood offers a sustainable alternative by using heat treatment without chemicals, reducing its environmental impact and enhancing durability naturally. Pressure-treated wood relies on chemical preservatives like copper compounds, which may pose environmental risks during production and disposal. Choosing thermally modified wood supports eco-friendly forest management and minimizes toxic leaching, aligning with green building standards and sustainable forestry practices.

Aesthetic Qualities and Color Changes

Thermally modified wood undergoes a heat treatment that enhances its rich, dark brown hues and deepens its natural grain patterns, offering a warm and elegant aesthetic. Pressure treated wood typically starts with a greenish or brownish tint due to chemical preservatives, which may fade or weather to a grayish tone over time, affecting its original appearance. Your choice depends on whether you prefer the stable, natural color evolution of thermally modified wood or the protective qualities with color changes associated with pressure treated wood.

Performance in Outdoor and Indoor Applications

Thermally modified wood offers superior dimensional stability and resistance to decay, making it an ideal choice for outdoor applications such as decking and cladding where reduced moisture uptake is crucial. Pressure treated wood excels in outdoor environments due to its chemical preservatives that protect against rot and insect damage, but it may release chemicals unsuitable for indoor use without proper sealing. Your decision should consider the wood's exposure to moisture and chemical safety requirements to ensure optimal performance in both outdoor and indoor settings.

Lifespan and Maintenance Requirements

Thermally modified wood typically lasts 20 to 30 years due to its enhanced resistance to decay and insects, requiring minimal maintenance like occasional cleaning and sealing. Pressure treated wood has a lifespan of 15 to 25 years but demands more frequent maintenance, including regular inspections for rot and reapplication of protective coatings. Both options improve durability over untreated wood, but thermally modified wood offers a longer lifespan with reduced upkeep.

Cost Comparison and Market Availability

Thermally modified wood generally has a higher upfront cost compared to pressure treated wood due to specialized heat treatment processes that enhance durability and stability. Pressure treated wood is more widely available in retail and wholesale markets, making it a cost-effective option for large-scale projects and budget-conscious consumers. Market trends indicate increased demand for thermally modified wood in eco-friendly and premium applications, despite its limited distribution channels relative to pressure treated wood.

Choosing the Right Wood for Your Project

Thermally modified wood offers enhanced durability, resistance to decay, and improved dimensional stability through a heat treatment process that alters its cellular structure without chemicals. Pressure treated wood is infused with chemical preservatives to protect against rot, insects, and moisture, making it ideal for outdoor projects exposed to harsh conditions. Your choice depends on the project's exposure, desired lifespan, and environmental preferences, with thermally modified wood being eco-friendlier and pressure treated wood providing stronger initial protection.

Thermally modified wood vs pressure treated wood Infographic

libmatt.com

libmatt.com