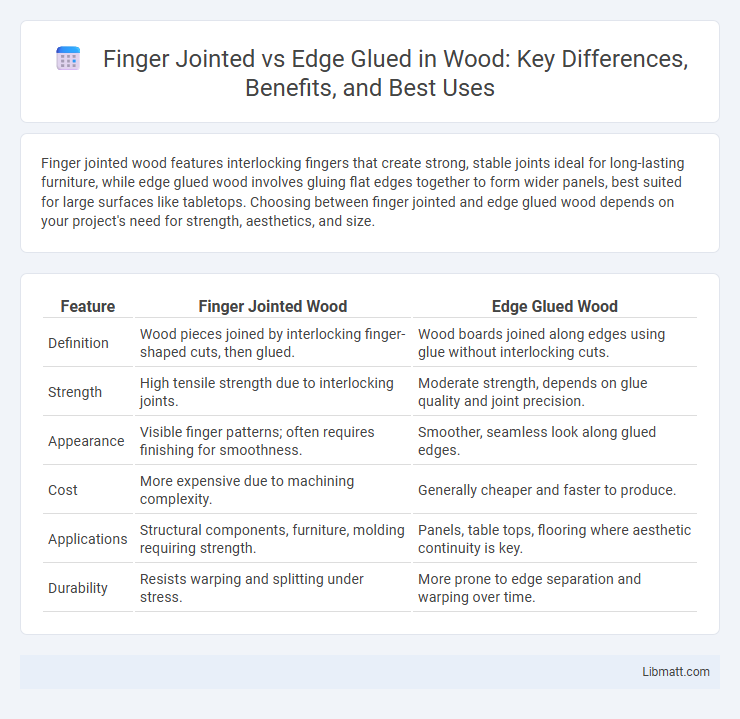

Finger jointed wood features interlocking fingers that create strong, stable joints ideal for long-lasting furniture, while edge glued wood involves gluing flat edges together to form wider panels, best suited for large surfaces like tabletops. Choosing between finger jointed and edge glued wood depends on your project's need for strength, aesthetics, and size.

Table of Comparison

| Feature | Finger Jointed Wood | Edge Glued Wood |

|---|---|---|

| Definition | Wood pieces joined by interlocking finger-shaped cuts, then glued. | Wood boards joined along edges using glue without interlocking cuts. |

| Strength | High tensile strength due to interlocking joints. | Moderate strength, depends on glue quality and joint precision. |

| Appearance | Visible finger patterns; often requires finishing for smoothness. | Smoother, seamless look along glued edges. |

| Cost | More expensive due to machining complexity. | Generally cheaper and faster to produce. |

| Applications | Structural components, furniture, molding requiring strength. | Panels, table tops, flooring where aesthetic continuity is key. |

| Durability | Resists warping and splitting under stress. | More prone to edge separation and warping over time. |

Introduction to Finger Jointed and Edge Glued Wood

Finger jointed wood consists of short wood pieces joined end-to-end with interlocking fingers, creating a strong, stable material ideal for longer boards. Edge glued wood is made by bonding narrow boards side-by-side with adhesive, producing wide panels with a smooth surface and consistent grain pattern. You can choose between finger jointed and edge glued wood based on the desired strength, appearance, and application in woodworking projects.

Defining Finger Jointed Wood

Finger jointed wood consists of small interlocking rectangular cuts at the ends of shorter wood pieces, creating a strong, stable joint that mimics the appearance of a single solid board. This method enhances wood stability and reduces warping compared to edge glued boards, which are formed by gluing edges of wood strips side by side without interlocking joints. Your choice between finger jointed and edge glued wood depends on the desired strength, uniformity, and application for woodworking projects.

Understanding Edge Glued Panels

Edge glued panels consist of multiple boards joined along their edges to create a wider, stable surface, commonly used in furniture and cabinetry for durability and cost efficiency. Unlike finger jointed panels, which interlock with precisely cut fingers for enhanced mechanical strength, edge glued panels rely primarily on adhesive strength and proper clamping. Understanding the benefits and limitations of edge glued panels helps you select the right wood construction method for your project's aesthetic and structural requirements.

Manufacturing Processes Compared

Finger jointed boards are created by interlocking small wood pieces using precision cuts and strong adhesive, resulting in enhanced stability and minimized material waste. Edge glued panels are made by aligning and gluing the long edges of solid wood pieces, offering a seamless appearance but requiring careful moisture control to prevent warping. Your choice between finger jointed and edge glued manufacturing depends on the desired strength, appearance, and cost-efficiency for your woodworking project.

Strength and Durability Differences

Finger jointed wood offers superior strength and durability due to its interlocking design, which distributes stress evenly across the joints and minimizes weak points. Edge glued boards rely solely on adhesive strength between flat surfaces, making them more susceptible to separation under heavy loads or moisture exposure. The mechanical interlock present in finger joints enhances resistance to warping and splitting, extending the lifespan of the wood in structural applications.

Visual Appearance and Grain Patterns

Finger jointed wood showcases a uniform, interlocking pattern where individual pieces are joined end to end, creating a distinct, segmented visual effect that differs from natural grain flow. Edge glued panels maintain continuous grain patterns across the surface, providing a seamless and natural wood appearance ideal for highlighting your wood's aesthetic qualities. Selecting between finger jointed and edge glued depends on whether you prefer a structured, patterned look or a smooth, authentic grain presentation.

Cost Considerations for Each Method

Finger jointed wood typically costs less due to efficient use of smaller wood pieces and reduced waste in manufacturing. Edge glued boards can be more expensive because they require longer, higher-quality lumber sections and precise alignment during assembly. Budget-conscious projects often favor finger jointing for affordability without sacrificing strength.

Common Applications and Uses

Finger jointed wood is commonly used in furniture manufacturing, door frames, and moldings due to its enhanced strength and stability, making it ideal for structural components. Edge glued panels are prevalent in tabletops, cabinetry, and shelving, offering a smooth, continuous surface suitable for aesthetic and load-bearing purposes. Both techniques optimize wood utilization by reducing waste and improving dimensional consistency in various woodworking projects.

Pros and Cons: Finger Jointed vs Edge Glued

Finger jointed wood offers enhanced strength and stability by interlocking multiple pieces, reducing warping and maximizing material use, but may show visible joints affecting aesthetics. Edge glued panels exhibit a seamless appearance ideal for larger surfaces, though they can be more prone to cupping and require careful moisture control. Your choice depends on whether you prioritize durability with intricate joints or a smooth, continuous wood grain finish.

Choosing the Right Option for Your Project

Finger jointed wood offers superior structural strength and stability, making it ideal for load-bearing applications and long spans due to its interlocking joint design. Edge glued wood provides a smooth, continuous surface that is perfect for aesthetic projects like furniture or paneling where appearance is paramount. Evaluate project needs based on strength requirements and visual appeal to select the optimal wood joining method.

Finger jointed vs edge glued Infographic

libmatt.com

libmatt.com