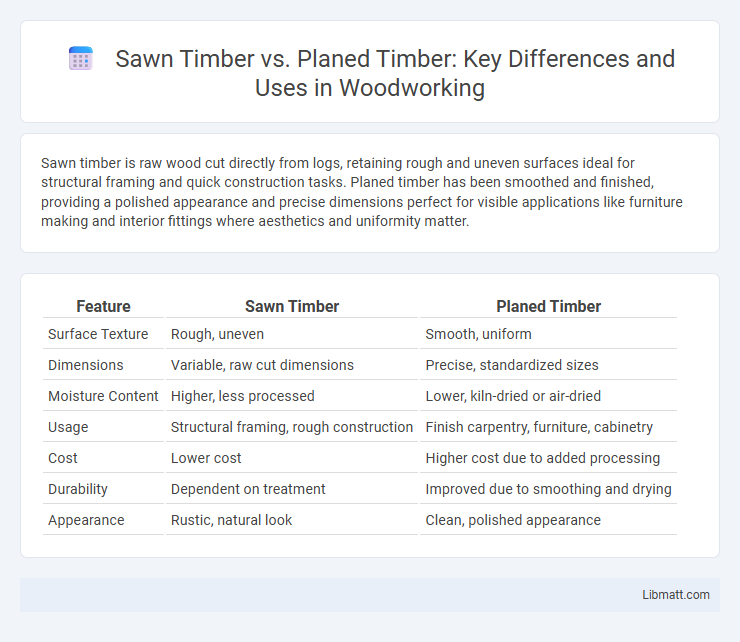

Sawn timber is raw wood cut directly from logs, retaining rough and uneven surfaces ideal for structural framing and quick construction tasks. Planed timber has been smoothed and finished, providing a polished appearance and precise dimensions perfect for visible applications like furniture making and interior fittings where aesthetics and uniformity matter.

Table of Comparison

| Feature | Sawn Timber | Planed Timber |

|---|---|---|

| Surface Texture | Rough, uneven | Smooth, uniform |

| Dimensions | Variable, raw cut dimensions | Precise, standardized sizes |

| Moisture Content | Higher, less processed | Lower, kiln-dried or air-dried |

| Usage | Structural framing, rough construction | Finish carpentry, furniture, cabinetry |

| Cost | Lower cost | Higher cost due to added processing |

| Durability | Dependent on treatment | Improved due to smoothing and drying |

| Appearance | Rustic, natural look | Clean, polished appearance |

Introduction to Sawn Timber and Planed Timber

Sawn timber refers to wood that has been cut directly from logs into rough, unprocessed planks or beams, retaining a coarse surface texture and natural imperfections. Planed timber, also known as planed all round (PAR), undergoes further milling with a planer to produce smooth, uniform surfaces and precise dimensions, making it ideal for finished woodworking projects. Understanding the distinction between sawn and planed timber is essential for selecting the appropriate material for construction, furniture making, or carpentry.

Definition and Key Differences

Sawn timber refers to wood that has been cut directly from logs into rough, unfinished boards, retaining a coarse texture and natural edges. Planed timber, in contrast, undergoes a mechanical process that smooths and evens the surface, resulting in uniform dimensions and a polished finish ideal for woodworking and construction. Understanding these definitions helps you choose the right type for projects requiring either raw structural strength or refined aesthetics.

Production Processes: Sawn vs. Planed

Sawn timber is produced by cutting logs into rough rectangular shapes using large saw blades, which results in a coarse surface with visible saw marks and an uneven texture. Planed timber undergoes an additional finishing process where the rough sawn surfaces are smoothed and leveled using a planing machine, resulting in a uniform thickness and a polished, smooth surface suitable for visible applications. The planing process improves dimensional accuracy and enhances the wood's aesthetic appeal, making planed timber preferred for furniture, interior joinery, and fine carpentry.

Surface Finish and Appearance Comparison

Sawn timber features a rough surface with visible saw marks, offering a more rustic and natural appearance ideal for structural or decorative projects where texture is desired. Planed timber undergoes a finishing process that smooths the surface, resulting in a cleaner, more polished look suited for furniture, cabinetry, and indoor trim. Understanding these differences helps you choose the appropriate timber type based on the desired aesthetic and finish for your project.

Dimensional Accuracy and Tolerances

Planed timber offers superior dimensional accuracy and tighter tolerances compared to sawn timber due to its smooth, uniform surface achieved through precise machining. Sawn timber often exhibits variable thickness and rough edges, leading to less consistent measurements and potential fitting issues in construction projects. Accurate dimensions in planed timber reduce the need for on-site adjustments, enhancing structural integrity and finishing precision.

Strength and Structural Performance

Sawn timber retains its natural texture and surface irregularities, which can influence its strength and structural performance compared to planed timber. Planed timber undergoes a smoothing process that removes surface defects, resulting in more consistent dimensions and improved load-bearing capacity. Your choice between sawn and planed timber should consider the specific structural requirements, as planed timber often offers greater reliability in strength-critical construction applications.

Cost Considerations and Price Differences

Sawn timber generally costs less than planed timber due to its rougher finish and less processing time, making it a more budget-friendly option for construction projects requiring large quantities. Planed timber undergoes additional milling for a smoother surface, increasing labor and machinery expenses, which typically results in a higher price point. Your choice depends on balancing cost with desired finish quality, as planed timber requires less preparation time but comes at a premium.

Common Applications and Uses

Sawn timber is commonly used in structural framing, fencing, and outdoor projects due to its rough texture and cost-effectiveness, making it ideal for construction where appearance is less critical. Planed timber, with its smooth surface and precise dimensions, is preferred for interior finishing, furniture making, and decorative applications that require a polished look. Your choice between sawn and planed timber depends on the visual and functional requirements of your project.

Environmental Impact and Sustainability

Sawn timber retains its natural surface, requiring less processing energy and producing fewer emissions compared to planed timber, making it a more environmentally friendly option. Planed timber undergoes additional milling to achieve a smooth finish, which increases energy consumption and waste generation during production. Choosing sawn timber supports sustainability by reducing the carbon footprint associated with wood processing and preserving more of the raw material for your construction or woodworking projects.

Choosing the Right Timber for Your Project

Sawn timber retains its natural rough texture and is ideal for structural applications requiring strength and cost-efficiency, whereas planed timber offers a smooth, finished surface suitable for visible elements such as furniture or trim. Choosing the right timber depends on the project's aesthetic requirements and functional demands, with sawn timber favored for framing and planed timber for decorative purposes. Understanding these differences ensures optimal performance and appearance in construction and woodworking projects.

Sawn timber vs Planed timber Infographic

libmatt.com

libmatt.com