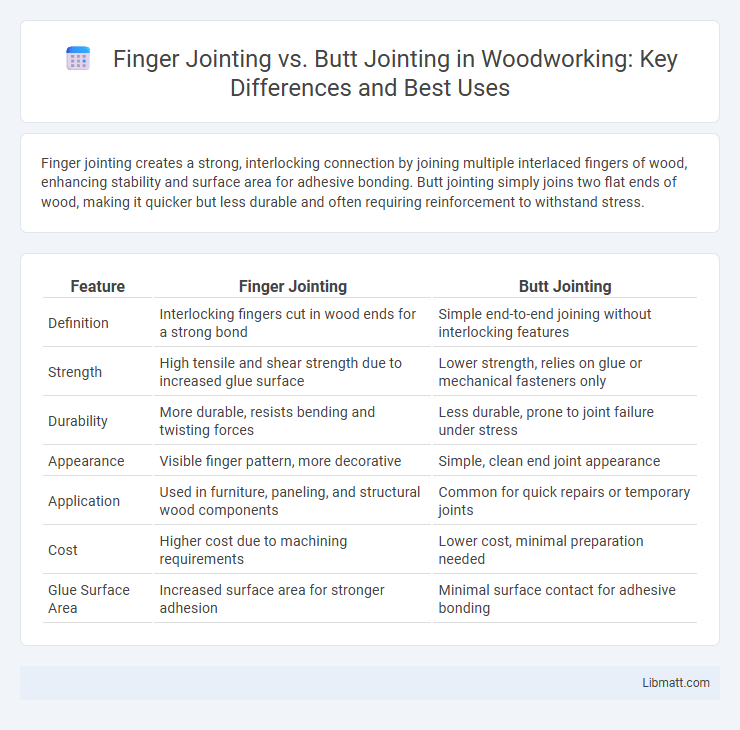

Finger jointing creates a strong, interlocking connection by joining multiple interlaced fingers of wood, enhancing stability and surface area for adhesive bonding. Butt jointing simply joins two flat ends of wood, making it quicker but less durable and often requiring reinforcement to withstand stress.

Table of Comparison

| Feature | Finger Jointing | Butt Jointing |

|---|---|---|

| Definition | Interlocking fingers cut in wood ends for a strong bond | Simple end-to-end joining without interlocking features |

| Strength | High tensile and shear strength due to increased glue surface | Lower strength, relies on glue or mechanical fasteners only |

| Durability | More durable, resists bending and twisting forces | Less durable, prone to joint failure under stress |

| Appearance | Visible finger pattern, more decorative | Simple, clean end joint appearance |

| Application | Used in furniture, paneling, and structural wood components | Common for quick repairs or temporary joints |

| Cost | Higher cost due to machining requirements | Lower cost, minimal preparation needed |

| Glue Surface Area | Increased surface area for stronger adhesion | Minimal surface contact for adhesive bonding |

Introduction to Wood Joinery Techniques

Finger jointing creates strong, interlocking joints by cutting a series of complementary grooves in two wooden pieces, enhancing surface area for glue adhesion and resulting in increased structural integrity. Butt jointing simply joins two wood pieces end-to-end without interlocking features, making it easier to execute but less durable under stress. Your choice depends on the required strength and application of the wood project.

What is Finger Jointing?

Finger jointing is a woodworking technique that involves joining two pieces of wood by cutting a series of interlocking rectangular "fingers" along the edges. This method increases the surface area for gluing, resulting in a stronger and more durable bond compared to butt jointing, where two pieces are simply butted together without interlocking features. Your choice of finger jointing enhances structural integrity and is ideal for creating longer lengths of timber from shorter pieces.

What is Butt Jointing?

Butt jointing is a woodworking technique where two pieces of wood are joined by simply butting their ends together without any special shaping or interlocking. This method relies heavily on adhesives, nails, or screws to hold the joint securely. Although easy to execute, butt joints typically offer lower strength and durability compared to more complex joints like finger jointing.

Structural Strength: Finger Joint vs. Butt Joint

Finger jointing provides superior structural strength compared to butt jointing by increasing the gluing surface area and interlocking multiple fingers, which distributes stress more evenly. Butt joints rely solely on the adhesive bond between two flat ends, making them weaker under tension and shear forces. This enhanced mechanical interlock in finger joints results in greater load-bearing capacity and durability in wood assemblies.

Durability and Longevity Comparison

Finger jointing offers superior durability and longevity compared to butt jointing due to its interlocking design, which provides increased surface area for adhesive bonding and enhanced structural integrity. The interdigitated fingers create a strong mechanical lock that distributes stress evenly, reducing the likelihood of joint failure over time. Your projects will benefit from finger jointing when long-lasting, high-strength joints are essential.

Aesthetic Differences Explained

Finger jointing creates a visually intricate, interlocking pattern that enhances the aesthetic appeal of wood edges, while butt jointing results in a simpler, less decorative seam. The complex, repeated notches of finger joints provide texture and a sense of craftsmanship, making them ideal for visible furniture parts or decorative moldings. Your choice between these methods will influence the overall visual impact and perceived quality of the wooden structure.

Cost and Material Efficiency

Finger jointing offers superior material efficiency by maximizing the use of shorter wood pieces through interlocking fingers that create a strong bond, reducing waste compared to butt jointing. Butt jointing, while simpler and less labor-intensive, often requires additional reinforcement and glue, which can increase overall costs and result in lower structural integrity. You can achieve cost savings with finger jointing due to its enhanced durability and efficient use of materials, despite the higher initial setup expenses.

Common Applications in Carpentry

Finger jointing is commonly used in furniture making, door frames, and moldings where strong, interlocking joints provide enhanced durability and aesthetic appeal. Butt jointing is often applied in framing, cabinet construction, and simple woodworking projects where quick, straightforward connections are sufficient. Your choice between finger jointing and butt jointing depends on the required joint strength and the level of precision for the carpentry application.

Assembly Process and Tools Required

Finger jointing involves interlocking multiple precise, evenly spaced fingers cut into two pieces of wood, requiring specialized saws or finger joint routers for accurate cuts and clamps for assembly. Butt jointing simply joins two flat-ended wood pieces without interlocking features, typically using basic tools like a saw, wood glue, and clamps. Your choice between finger and butt joints affects the complexity of the assembly process and the range of tools needed, with finger joints demanding more precision and specialized equipment.

Choosing the Right Joint for Your Project

Finger jointing offers superior strength and durability by interlocking multiple fingers, ideal for load-bearing wooden structures and precise woodworking projects. Butt jointing is simpler and faster to execute but provides less mechanical strength, making it suitable for non-structural applications or where quick assembly is prioritized. Evaluating the project's load requirements, aesthetic preferences, and available tools ensures the right joint selection for optimal performance and longevity.

Finger jointing vs butt jointing Infographic

libmatt.com

libmatt.com