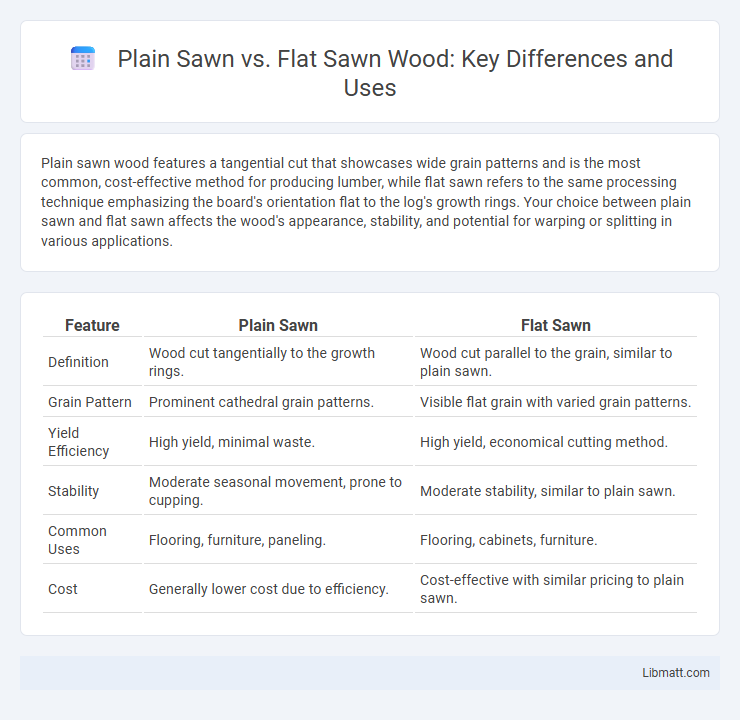

Plain sawn wood features a tangential cut that showcases wide grain patterns and is the most common, cost-effective method for producing lumber, while flat sawn refers to the same processing technique emphasizing the board's orientation flat to the log's growth rings. Your choice between plain sawn and flat sawn affects the wood's appearance, stability, and potential for warping or splitting in various applications.

Table of Comparison

| Feature | Plain Sawn | Flat Sawn |

|---|---|---|

| Definition | Wood cut tangentially to the growth rings. | Wood cut parallel to the grain, similar to plain sawn. |

| Grain Pattern | Prominent cathedral grain patterns. | Visible flat grain with varied grain patterns. |

| Yield Efficiency | High yield, minimal waste. | High yield, economical cutting method. |

| Stability | Moderate seasonal movement, prone to cupping. | Moderate stability, similar to plain sawn. |

| Common Uses | Flooring, furniture, paneling. | Flooring, cabinets, furniture. |

| Cost | Generally lower cost due to efficiency. | Cost-effective with similar pricing to plain sawn. |

Introduction to Lumber Sawn Methods

Plain sawn, also known as flat sawn, is the most common lumber sawing method that cuts logs tangentially to the growth rings, producing boards with a distinctive grain pattern and increased width. This method maximizes yield from the log, making it cost-effective for producing flooring, furniture, and paneling. Understanding these sawing techniques helps you select lumber with desired aesthetic and structural properties for your woodworking projects.

What Is Plain Sawn Lumber?

Plain sawn lumber, also known as flat sawn, refers to wood cut tangentially to the growth rings, producing a distinctive grain pattern with wide, irregular figures. This method maximizes yield and is the most common and cost-effective way to mill lumber, making it ideal for general construction and cabinetry. When selecting wood for your project, understanding the characteristics of plain sawn lumber helps ensure optimal appearance and performance.

What Is Flat Sawn Lumber?

Flat sawn lumber, also known as plain sawn lumber, is the most common type of wood cut where logs are sliced tangentially to the growth rings, producing boards with a distinctive grain pattern featuring cathedral-like arches. This method maximizes board width and yields more usable lumber, making it cost-effective for construction and furniture making. Your choice of flat sawn lumber offers a balance of aesthetic appeal and affordability due to its versatile grain and efficient processing.

Plain Sawn vs Flat Sawn: Are They the Same?

Plain sawn and flat sawn refer to the same wood cutting method that maximizes the yield from a log by slicing it tangentially to the growth rings, creating boards with a distinctive grain pattern. This technique is the most common and economical way to produce lumber, resulting in wide boards with varied grain appearances. Understanding that plain sawn and flat sawn are interchangeable terms helps you make informed decisions when selecting wood for your projects.

Key Characteristics of Plain Sawn Lumber

Plain sawn lumber, also called flat sawn, features a distinct grain pattern with wide, cathedral-shaped arcs and a broad face grain. This cutting method maximizes yield from the log, resulting in more economical lumber with varied grain orientation that can cause more warping or cupping compared to other cuts. Your projects benefit from the natural aesthetic and cost-effectiveness of plain sawn boards, ideal for furniture and flooring where stability is less critical.

Advantages of Flat Sawn Lumber

Flat sawn lumber offers greater dimensional stability and a more uniform grain pattern compared to plain sawn wood, making it ideal for applications requiring consistent appearance and strength. The sawing process maximizes yield from the log, reducing waste and cost while providing broader boards that are easier to work with for your woodworking projects. This type of lumber also tends to have enhanced resistance to cupping and twisting, extending the durability of your finished product.

Drawbacks of Plain Sawn and Flat Sawn Methods

Plain sawn or flat sawn lumber often faces drawbacks such as increased susceptibility to warping, cupping, and uneven shrinkage due to its growth ring orientation. This method can result in less dimensional stability compared to quarter sawn or rift sawn wood, which may affect the longevity and appearance of Your woodworking projects. Additionally, plain sawn boards tend to have more prominent grain patterns but are prone to development of cracks and splits over time.

Grain Patterns: Visual Differences

Plain sawn and flat sawn lumber exhibit distinctive grain patterns that influence their visual appeal. Plain sawn wood showcases a cathedral or flame-shaped grain pattern, creating a dynamic and traditional look often favored in flooring and furniture. Your choice between plain sawn and flat sawn affects the aesthetic character, with plain sawn offering more pronounced, varied grain visuals compared to the straighter, more uniform appearance of other sawing methods.

Common Uses for Plain Sawn and Flat Sawn Wood

Plain sawn and flat sawn wood are widely used in furniture making, flooring, and paneling due to their affordability and attractive grain patterns. These cuts maximize yield from a log, making them ideal for construction projects and cabinetry where visual appeal and cost efficiency are important. Your choice between plain sawn and flat sawn wood will impact the final product's durability and aesthetic, especially in applications requiring resistance to warping.

Choosing Between Plain Sawn and Flat Sawn Lumber

Choosing between plain sawn and flat sawn lumber depends on the desired aesthetic, budget, and structural requirements. Plain sawn lumber offers broad grain patterns and is typically more affordable due to efficient log usage, while flat sawn lumber--often used synonymously with plain sawn--emphasizes the same sawing technique that results in similar visual characteristics and shrinkage properties. Understanding the distinction helps in selecting wood with optimal stability, grain appearance, and cost-effectiveness for woodworking and construction projects.

Plain sawn vs Flat sawn Infographic

libmatt.com

libmatt.com