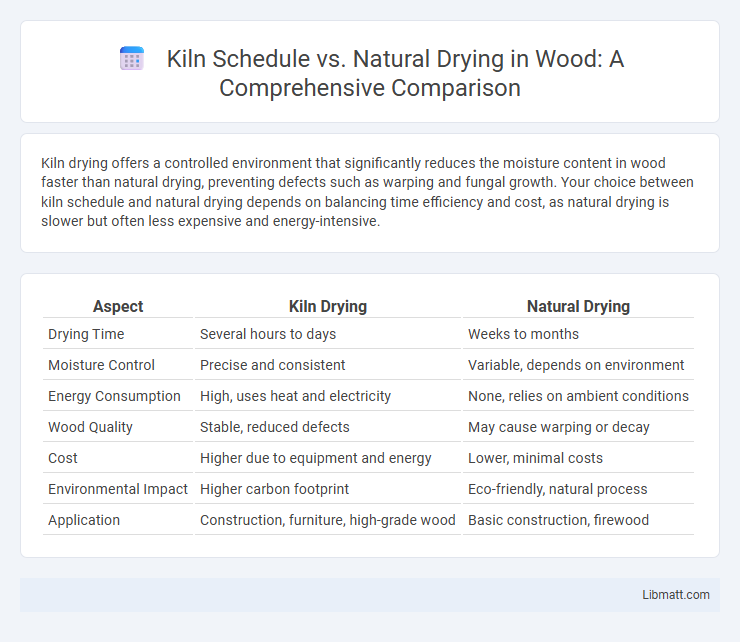

Kiln drying offers a controlled environment that significantly reduces the moisture content in wood faster than natural drying, preventing defects such as warping and fungal growth. Your choice between kiln schedule and natural drying depends on balancing time efficiency and cost, as natural drying is slower but often less expensive and energy-intensive.

Table of Comparison

| Aspect | Kiln Drying | Natural Drying |

|---|---|---|

| Drying Time | Several hours to days | Weeks to months |

| Moisture Control | Precise and consistent | Variable, depends on environment |

| Energy Consumption | High, uses heat and electricity | None, relies on ambient conditions |

| Wood Quality | Stable, reduced defects | May cause warping or decay |

| Cost | Higher due to equipment and energy | Lower, minimal costs |

| Environmental Impact | Higher carbon footprint | Eco-friendly, natural process |

| Application | Construction, furniture, high-grade wood | Basic construction, firewood |

Introduction to Lumber Drying Methods

Kiln drying accelerates moisture removal from lumber through controlled temperature, humidity, and airflow, ensuring uniform drying and reducing defects like warping and checking. Natural drying, or air drying, relies on ambient conditions, which can be slower and less predictable but is energy-efficient and preserves certain wood qualities. Choosing the right drying method impacts Your lumber's durability, stability, and suitability for specific woodworking projects.

Overview of Kiln Drying

Kiln drying accelerates the moisture removal process from wood by using controlled heat, humidity, and airflow, reducing drying time from months to days. This method improves wood stability, minimizes defects such as warping and checking, and enhances strength compared to natural drying. Kiln schedules vary based on wood species, thickness, and final moisture content requirements, ensuring optimized drying efficiency and product quality.

Understanding Natural Drying (Air Drying)

Natural drying, also known as air drying, involves drying wood by exposing it to ambient air conditions, which reduces moisture content gradually and uniformly. This method relies heavily on environmental factors like temperature, humidity, and airflow, often resulting in longer drying times compared to kiln schedules. Understanding natural drying is essential for optimizing wood quality, as it minimizes internal stresses and risk of defects such as warping and cracking.

Kiln Schedule: Definition and Process

A kiln schedule is a carefully designed sequence of temperature and humidity settings used to accelerate the drying process of wood in a controlled environment. This method involves monitoring moisture content and adjusting heat and airflow to reduce drying time while minimizing defects such as warping or cracking. Kiln drying ensures uniform moisture removal and enhances wood stability compared to slower natural drying methods.

Factors Influencing Kiln Drying Schedules

Kiln drying schedules are influenced by factors such as wood species, moisture content, thickness, and desired final moisture level, which determine the temperature, humidity, and airflow settings. Unlike natural drying, kiln drying accelerates moisture removal by controlling environmental conditions, reducing drying time and minimizing defects like warping or checking. Your choice of drying method impacts the wood's stability and quality, as kiln schedules are tailored to optimize drying efficiency based on these critical variables.

Key Differences Between Kiln Drying and Natural Drying

Kiln drying uses controlled heat and humidity to reduce wood moisture content rapidly and uniformly, resulting in faster processing times and consistent results compared to natural drying. Natural drying relies on ambient air and weather conditions, which can lead to longer drying periods and variability in moisture levels. Kiln drying minimizes defects such as warping and checking that are more common with natural drying due to uncontrolled environmental exposure.

Pros and Cons of Kiln Drying

Kiln drying offers precise moisture control, reducing the risk of warping and fungal growth compared to natural drying, and accelerates the drying process from months to days, improving production efficiency for furniture and construction lumber. However, high energy consumption increases operational costs and environmental impact, while improper kiln schedules can cause defects like surface checking or internal stresses. Kiln drying also limits drying capacity based on kiln size, requiring careful scheduling to maximize throughput without compromising wood quality.

Pros and Cons of Natural Drying

Natural drying offers cost savings by eliminating the need for expensive kiln equipment and energy consumption, making it environmentally friendly. However, it requires longer drying times, often several weeks or months, which can delay production and increase vulnerability to weather-related issues like mold or warping. Your choice depends on balancing these economic and quality considerations against project timelines and wood stability needs.

Environmental and Cost Considerations

Kiln drying consumes significant energy, increasing operational costs and carbon emissions compared to natural drying, which relies on ambient conditions and has minimal environmental impact. Natural drying requires more time and space, potentially leading to higher indirect costs such as inventory storage and risk of mold, while kiln drying's accelerated process reduces these risks but involves substantial electricity or fuel expenses. Choosing between kiln schedule and natural drying depends on balancing faster production turnaround and the environmental footprint with cost efficiency and sustainability goals.

Choosing the Best Drying Method for Your Needs

Kiln drying offers precise control over temperature, humidity, and airflow, resulting in faster and more consistent moisture removal compared to natural drying, which relies on ambient conditions and can be unpredictable. Your choice between kiln schedule and natural drying should consider factors such as desired drying time, wood species, and end-use requirements. Kiln drying is ideal for high-quality finishes and minimizing defects, while natural drying remains cost-effective for slower, less intensive projects.

Kiln schedule vs Natural drying Infographic

libmatt.com

libmatt.com