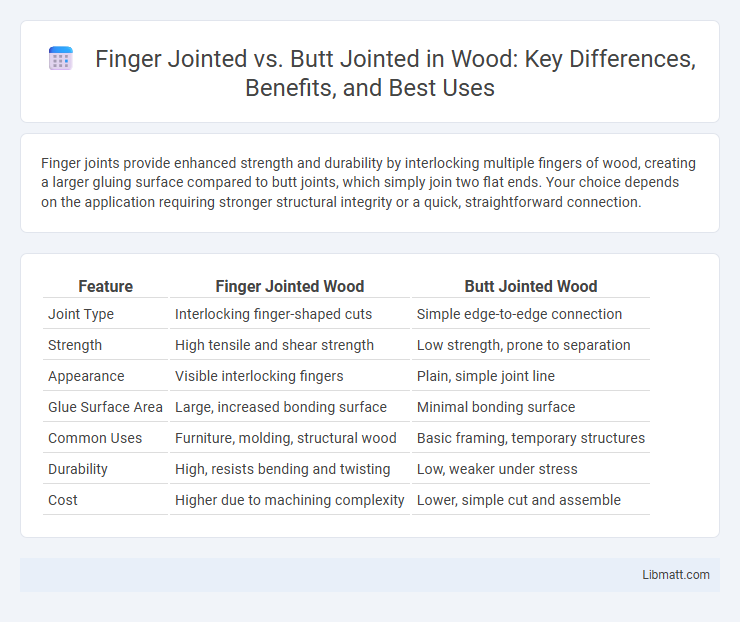

Finger joints provide enhanced strength and durability by interlocking multiple fingers of wood, creating a larger gluing surface compared to butt joints, which simply join two flat ends. Your choice depends on the application requiring stronger structural integrity or a quick, straightforward connection.

Table of Comparison

| Feature | Finger Jointed Wood | Butt Jointed Wood |

|---|---|---|

| Joint Type | Interlocking finger-shaped cuts | Simple edge-to-edge connection |

| Strength | High tensile and shear strength | Low strength, prone to separation |

| Appearance | Visible interlocking fingers | Plain, simple joint line |

| Glue Surface Area | Large, increased bonding surface | Minimal bonding surface |

| Common Uses | Furniture, molding, structural wood | Basic framing, temporary structures |

| Durability | High, resists bending and twisting | Low, weaker under stress |

| Cost | Higher due to machining complexity | Lower, simple cut and assemble |

Introduction to Wood Joinery Techniques

Finger jointed wood involves interlocking multiple small fingers cut into the pieces, creating a strong and durable bond with increased surface area for gluing. Butt jointed wood simply joins two flat ends together without interlocking, resulting in a weaker connection that often requires reinforcement like nails or screws. Understanding these fundamental wood joinery techniques helps you select the appropriate method for structural integrity and aesthetic appeal in woodworking projects.

What is a Finger Joint?

A finger joint is a woodworking technique where two pieces of wood are cut into interlocking rectangular "fingers" that fit together like puzzle pieces, creating a strong and stable joint. This joint type increases the surface area for glue, ensuring enhanced durability compared to a butt joint, which simply joins two flat ends. Your projects benefit from finger joints in applications demanding high strength and aesthetic appeal, such as furniture and cabinetry.

What is a Butt Joint?

A butt joint is a simple woodworking technique where two pieces of wood are joined by placing their flat ends together without any special shaping. This joint relies primarily on glue, nails, or screws for strength and is commonly used in framing and basic construction due to its straightforward assembly. While easy to make, butt joints generally provide less mechanical strength compared to finger joints, which have interlocking fingers for improved durability.

Structural Strength: Finger Joint vs Butt Joint

Finger joints offer superior structural strength compared to butt joints due to their interlocking design, which increases the glue surface area and enhances load distribution. Butt joints rely solely on adhesive or fasteners at the end grain, making them weaker and more prone to failure under stress. Engineering tests confirm finger joints can achieve up to 70% greater tensile strength than butt joints in woodworking and construction applications.

Aesthetic Differences Between Finger and Butt Joints

Finger joints showcase a distinctive, interlocking pattern that enhances visual appeal with a decorative, geometric look, often highlighting craftsmanship and precision woodworking. Butt joints present a simpler, seamless appearance with edges joined directly, creating a clean and minimalistic aesthetic suitable for modern or understated designs. The choice between finger and butt joints significantly influences the overall style, with finger joints adding texture and complexity while butt joints offer smooth and subtle finishes.

Applications: When to Use Finger Joints

Finger joints provide superior strength and stability, making them ideal for applications requiring durable, load-bearing connections such as furniture, cabinetry, and door frames. Their interlocking design distributes stress evenly, enhancing resistance to tension and compression compared to butt joints, which are better suited for simple, non-structural assemblies. Finger joints also excel in aesthetic appeal, offering a decorative edge that complements fine woodworking projects demanding precision and longevity.

Applications: When to Use Butt Joints

Butt joints are ideal for simple woodworking projects where speed and ease of assembly are prioritized, such as framing, basic furniture, and temporary structures. They perform well in applications where joint strength is less critical and can be reinforced with nails, screws, or adhesives. Common uses include cabinet carcasses, picture frames, and basic shelving systems that do not endure heavy loads or stress.

Cost and Material Efficiency Comparison

Finger joints offer superior material efficiency by interlocking wood pieces, reducing waste and increasing surface area for adhesive bonding, which results in stronger joints and lower repair costs. Butt joints are simpler and cheaper to produce initially but often require additional fasteners or reinforcements, leading to higher overall material and labor costs. Choosing finger joints maximizes durability and cost-effectiveness in woodworking projects through optimized use of materials and extended product lifespan.

Durability and Longevity of Each Joint

Finger joints offer superior durability and longevity compared to butt joints due to their interlocking design, which provides a larger gluing surface and stronger mechanical bond. Butt joints rely solely on adhesive strength at the end grain, making them more prone to failure under stress or over time. Consequently, finger jointed constructions maintain structural integrity longer, especially in load-bearing applications and environments with fluctuating humidity and temperature.

Choosing the Right Joint for Your Woodworking Project

Finger joints provide superior strength and alignment, making them ideal for load-bearing woodworking projects such as furniture and cabinetry. Butt joints are simpler and quicker to create but require reinforcement with screws, nails, or glue to ensure durability. Consider the weight and aesthetic requirements of your project to determine whether the precision and interlocking nature of finger joints or the ease and speed of butt joints best suit your woodworking needs.

Finger jointed vs butt jointed Infographic

libmatt.com

libmatt.com