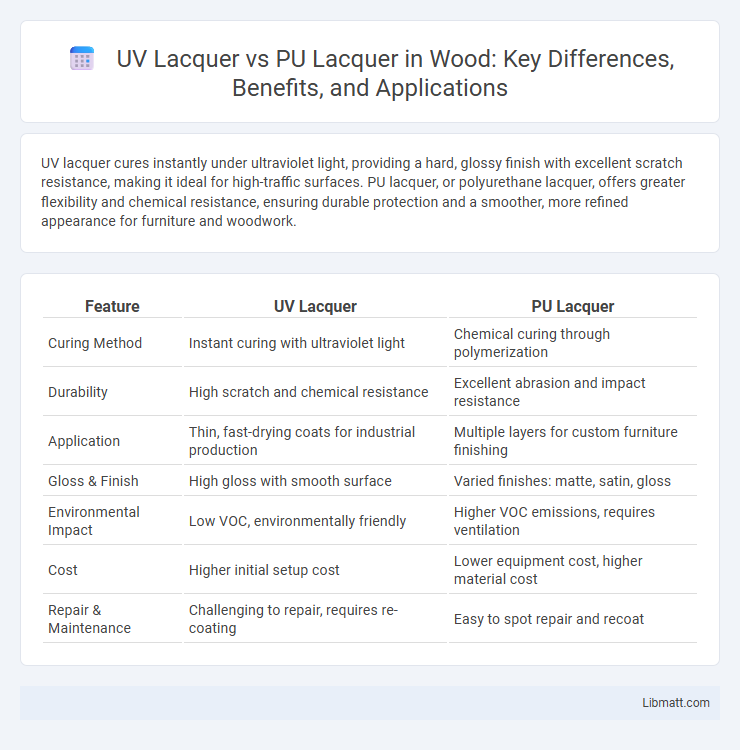

UV lacquer cures instantly under ultraviolet light, providing a hard, glossy finish with excellent scratch resistance, making it ideal for high-traffic surfaces. PU lacquer, or polyurethane lacquer, offers greater flexibility and chemical resistance, ensuring durable protection and a smoother, more refined appearance for furniture and woodwork.

Table of Comparison

| Feature | UV Lacquer | PU Lacquer |

|---|---|---|

| Curing Method | Instant curing with ultraviolet light | Chemical curing through polymerization |

| Durability | High scratch and chemical resistance | Excellent abrasion and impact resistance |

| Application | Thin, fast-drying coats for industrial production | Multiple layers for custom furniture finishing |

| Gloss & Finish | High gloss with smooth surface | Varied finishes: matte, satin, gloss |

| Environmental Impact | Low VOC, environmentally friendly | Higher VOC emissions, requires ventilation |

| Cost | Higher initial setup cost | Lower equipment cost, higher material cost |

| Repair & Maintenance | Challenging to repair, requires re-coating | Easy to spot repair and recoat |

Introduction to UV Lacquer and PU Lacquer

UV lacquer cures instantly under ultraviolet light, creating a hard and durable finish highly resistant to scratches and chemicals. PU lacquer, or polyurethane lacquer, offers excellent elasticity and abrasion resistance, making it ideal for surfaces requiring flexibility and long-lasting protection. Choosing between UV lacquer and PU lacquer depends on Your project's need for curing speed, durability, and application environment.

Chemical Composition and Curing Process

UV lacquer consists of oligomers and monomers that cure through a photopolymerization process activated by ultraviolet light, resulting in rapid hardening and a durable finish. PU lacquer, or polyurethane lacquer, is composed of polyurethane resins that cure via a chemical reaction between polyols and isocyanates, forming a tough, flexible coating through moisture or heat curing. The UV lacquering process offers faster drying times and higher resistance to abrasion, while PU lacquer provides superior chemical resistance and elasticity due to its different curing mechanism.

Application Methods Compared

UV lacquer cures instantly under ultraviolet light, enabling faster production cycles and minimal drying time compared to PU lacquer, which requires air drying or heat. PU lacquer offers more versatile application methods, including spraying, brushing, or dipping, making it suitable for complex surfaces and thicker coatings. The choice between UV and PU lacquers depends largely on the desired finish speed, flexibility in application, and curing environment.

Drying and Curing Time Differences

UV lacquer dries and cures almost instantly when exposed to ultraviolet light, providing a significant time advantage over PU lacquer, which relies on air drying and can take several hours to fully cure. The rapid curing process of UV lacquer reduces production time and increases efficiency in manufacturing environments. PU lacquer requires additional time for solvent evaporation and chemical curing, which can extend drying times and affect overall workflow speed.

Durability and Scratch Resistance

UV lacquer offers superior durability and scratch resistance due to its rapid curing process, which creates a hard, resilient surface ideal for high-traffic areas. PU lacquer, while providing good flexibility and a smooth finish, tends to be less resistant to scratches and wear over time compared to UV coatings. For applications demanding long-lasting protection and enhanced surface hardness, UV lacquer is generally the preferred choice.

Environmental Impact and Safety

UV lacquer offers a lower environmental impact compared to PU lacquer due to its rapid curing process, which reduces volatile organic compound (VOC) emissions significantly. PU lacquer contains solvents that release higher levels of VOCs, posing greater health risks and requiring careful handling and ventilation to ensure your safety. Choosing UV lacquer supports eco-friendlier production while minimizing harmful exposure during application.

Appearance: Gloss, Clarity, and Texture

UV lacquer offers superior clarity and high gloss finish due to its rapid curing process, resulting in a glass-like smooth surface with excellent light reflection. PU lacquer generally provides a warmer, richer appearance with less gloss but greater depth and texture, often preferred for natural wood aesthetics. While UV lacquer creates a harder, more resistant surface, PU lacquer allows for varied textures, enhancing tactile appeal and richness in finishing.

Cost and Long-Term Value

UV lacquer typically has a higher upfront cost due to advanced curing technology but offers excellent durability and faster drying times, enhancing production efficiency. PU lacquer tends to be more affordable initially but may require more frequent maintenance or reapplication over time, potentially increasing long-term expenses. Considering longevity and maintenance, UV lacquer often provides better long-term value despite its higher initial investment.

Maintenance and Repair Considerations

UV lacquer offers superior durability with a hard finish that resists scratches and stains, requiring minimal maintenance and easy cleaning for Your surfaces. PU lacquer, while providing a flexible and smooth finish, may demand more frequent touch-ups due to its vulnerability to wear and chemical damage. Repairing UV lacquer often involves reapplying a UV-cured layer that bonds seamlessly, whereas PU lacquer repairs typically need sanding and recoating, making maintenance less convenient.

Ideal Uses: Best Applications for Each Finish

UV lacquer is ideal for surfaces that require fast curing and high durability, such as cabinetry, flooring, and furniture exposed to heavy wear. PU lacquer excels in applications demanding superior chemical and moisture resistance, making it suitable for exterior woodwork, automotive parts, and high-end furniture. Both finishes provide excellent protection but cater to different environmental conditions and usage requirements.

UV lacquer vs PU lacquer Infographic

libmatt.com

libmatt.com