Snipe occurs when the first or last sheet in a printing or binding process is partially cut off or damaged, affecting the final product's edge quality. Tearout refers to the unwanted ripping or pulling of paper fibers during cutting or handling, which can compromise Your document's appearance and durability.

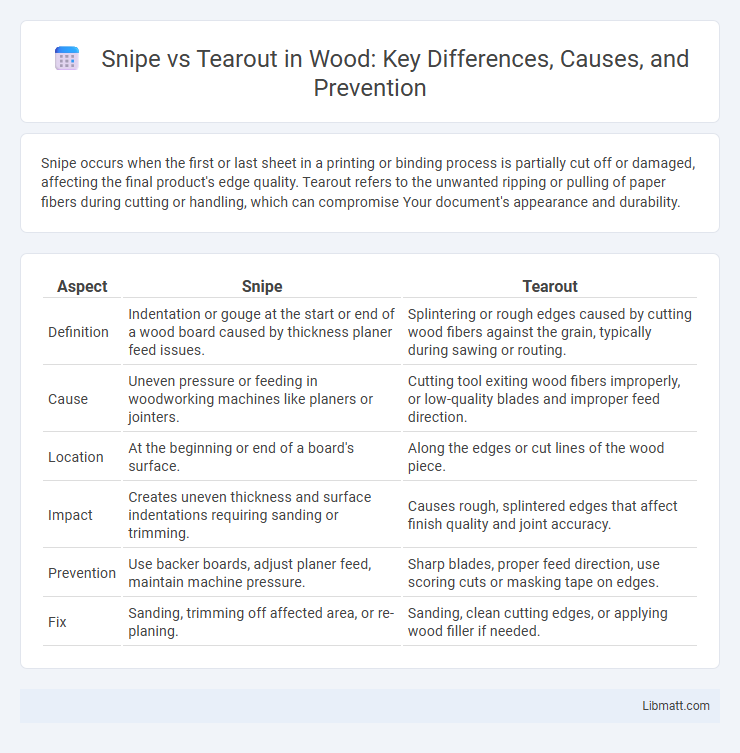

Table of Comparison

| Aspect | Snipe | Tearout |

|---|---|---|

| Definition | Indentation or gouge at the start or end of a wood board caused by thickness planer feed issues. | Splintering or rough edges caused by cutting wood fibers against the grain, typically during sawing or routing. |

| Cause | Uneven pressure or feeding in woodworking machines like planers or jointers. | Cutting tool exiting wood fibers improperly, or low-quality blades and improper feed direction. |

| Location | At the beginning or end of a board's surface. | Along the edges or cut lines of the wood piece. |

| Impact | Creates uneven thickness and surface indentations requiring sanding or trimming. | Causes rough, splintered edges that affect finish quality and joint accuracy. |

| Prevention | Use backer boards, adjust planer feed, maintain machine pressure. | Sharp blades, proper feed direction, use scoring cuts or masking tape on edges. |

| Fix | Sanding, trimming off affected area, or re-planing. | Sanding, clean cutting edges, or applying wood filler if needed. |

Introduction to Snipe and Tearout

Snipe and Tearout are dynamic maneuver-based games emphasizing precision and speed within compact arenas. Snipe challenges players to outmaneuver opponents using accurate targeting and quick reflexes, whereas Tearout focuses on high-octane vehicle combat with customizable cars and explosive power-ups. Both games leverage real-time multiplayer mechanics to deliver intense, competitive experiences for gamers seeking fast-paced action.

Defining Snipe in Woodworking

Snipe in woodworking refers to the unintended deeper cut or groove at the beginning or end of a board when feeding it through a planer or jointer, often caused by uneven pressure or alignment issues. This defect results in a noticeably shorter board edge that requires additional trimming or sanding to achieve a smooth, uniform surface. Understanding and preventing snipe is essential for maintaining precise dimensions and high-quality finishes in wood fabrication.

Understanding Tearout: Causes and Effects

Tearout occurs when wood fibers are forcibly ripped out rather than cleanly cut, often caused by using dull blades, incorrect feed rates, or improper tool alignment. This defect compromises the surface quality and can result in additional sanding or reparative work to achieve a smooth finish. Understanding the causes of tearout helps you select the right tools and settings to minimize damage and maintain the integrity of your woodworking projects.

Key Differences Between Snipe and Tearout

Snipe and tearout both affect woodworking edges but differ in cause and appearance; snipe is a shallow depression at the start or end of a board caused by improper feeding in planers or jointers, while tearout results from wood fibers being torn rather than cleanly cut, often due to dull blades or improper grain direction. Understanding these distinctions helps in choosing appropriate machine settings and blade sharpness to improve finish quality. Your project's edge smoothness depends on addressing the unique problems each defect presents.

Common Causes of Snipe

Snipe commonly occurs when the metal sheet slips during feeding into the shear, causing an uneven cut at the beginning or end of the material. Machine settings such as incorrect blade clearance, dull blades, or inconsistent hold-down pressure contribute significantly to this defect. Understanding these factors can help you adjust your process to minimize snipe and improve cut quality.

Main Factors Leading to Tearout

Tearout in woodworking primarily results from the grain direction, tool sharpness, and feed rate. When the cutting tool moves against the grain or is dull, fibers tend to lift and break unevenly, causing tearout. High feed rates and improper support of the wood fibers during cutting also increase the likelihood of tearout compared to the clean, controlled cuts typical of snipe.

Preventing Snipe in Your Projects

Preventing snipe in your projects requires careful planning and effective communication among team members to ensure that tasks are properly assigned and tracked. Utilizing project management tools such as Tearout can help identify potential for snipe by highlighting unclaimed or overlooked work early on. By proactively monitoring task status and fostering collaboration, you can reduce the risk of snipe undermining project goals and timelines.

Techniques to Minimize Tearout

To minimize tearout when working with wood, using sharp, high-quality blades or bits is essential for cleaner cuts. Techniques such as scoring the wood grain before the main cut or using backing boards to support the fibers can significantly reduce splintering. You can also adjust feed rates and cutting depth to ensure smoother finishes and less tearout during your woodworking projects.

Tools and Equipment to Combat Snipe and Tearout

Specialized tools like snipe and tearout prevention clamps, edge banding trimmers, and high-precision router bits are essential in combating snipe and tearout. Using quality woodworking equipment such as zero-clearance inserts and sharp carbide blades reduces the risk of damage on workpieces. Your workshop benefits from investing in these tools to ensure cleaner cuts and smoother edges, minimizing material waste.

Choosing the Right Method for Cleaner Cuts

Snipe and tearout are common cutting issues that affect precision in woodworking and CNC projects, with snipe causing unwanted depressions at the start or end of cuts and tearout resulting in rough, splintered edges. Selecting the right method involves adjusting feed rates, using proper sharp blades, and employing sacrificial backer boards to minimize these defects. Understanding the material type and machine settings ensures cleaner cuts, improving overall finish quality and reducing post-processing efforts.

Snipe vs Tearout Infographic

libmatt.com

libmatt.com