Lignin provides structural support and rigidity to plants by binding cellulose fibers together, making cell walls stronger and more resistant to degradation. Your understanding of biomass conversion improves by recognizing that cellulose is a carbohydrate responsible for energy storage and forms the primary component of plant cell walls, making it easier to break down into sugars for biofuel production.

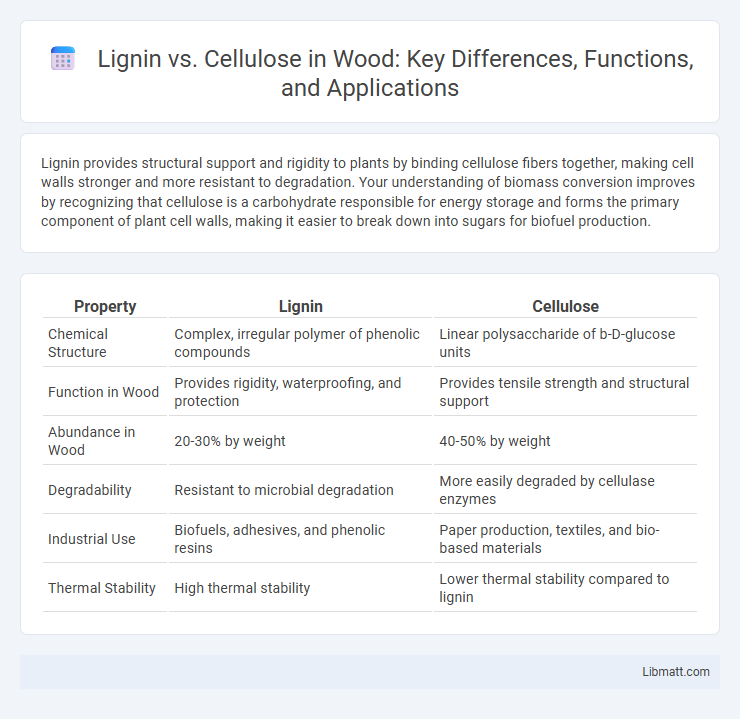

Table of Comparison

| Property | Lignin | Cellulose |

|---|---|---|

| Chemical Structure | Complex, irregular polymer of phenolic compounds | Linear polysaccharide of b-D-glucose units |

| Function in Wood | Provides rigidity, waterproofing, and protection | Provides tensile strength and structural support |

| Abundance in Wood | 20-30% by weight | 40-50% by weight |

| Degradability | Resistant to microbial degradation | More easily degraded by cellulase enzymes |

| Industrial Use | Biofuels, adhesives, and phenolic resins | Paper production, textiles, and bio-based materials |

| Thermal Stability | High thermal stability | Lower thermal stability compared to lignin |

Introduction to Lignin and Cellulose

Lignin and cellulose are essential biopolymers found in plant cell walls, with cellulose providing structural support through its fibrous nature composed of glucose units. Lignin acts as a complex aromatic polymer that binds cellulose fibers, enhancing rigidity and resistance to microbial degradation. Understanding the distinct chemical structures of lignin and cellulose helps optimize biomass processing and utilization in industries like biofuel production and paper manufacturing.

Chemical Structures Compared

Lignin and cellulose differ significantly in their chemical structures, impacting their properties and functions. Cellulose consists of linear chains of b-D-glucose units linked by b-1,4-glycosidic bonds, forming rigid, crystalline microfibrils that provide structural support in plant cell walls. Lignin is a complex, irregular polymer composed of phenolic compounds such as coniferyl, sinapyl, and p-coumaryl alcohols, creating a three-dimensional, cross-linked network that adds rigidity and hydrophobicity to your plant tissue.

Sources and Natural Occurrence

Lignin is predominantly found in the cell walls of woody plants, contributing to their rigidity and resistance to microbial attack, whereas cellulose is the most abundant organic polymer on Earth, primarily forming the structural framework of plant cell walls. Lignin occurs naturally in gymnosperms and angiosperms, especially in softwoods and hardwoods, while cellulose is present in almost all plant tissues, including cotton fibers, wood pulp, and plant stems. Both lignin and cellulose are integral components of biomass used in biofuel production, paper manufacturing, and biocomposite materials.

Roles in Plant Biology

Lignin provides structural support and rigidity to plant cell walls, enhancing resistance to decay and pathogens, while cellulose forms the primary structural component of the plant cell wall, offering tensile strength and flexibility. Cellulose microfibrils create a framework that supports cell shape and growth, whereas lignin acts as a hydrophobic barrier, facilitating water transport and mechanical stability. Together, lignin and cellulose contribute to the plant's overall structural integrity and defense mechanisms.

Physical Properties and Differences

Lignin is a complex, amorphous polymer providing rigidity and hydrophobicity to plant cell walls, making it denser and less flexible compared to cellulose. Cellulose consists of linear chains of glucose units forming crystalline structures that are strong, fibrous, and hydrophilic, contributing to tensile strength and firmness. Understanding these physical differences helps you optimize material selection in applications like bio-composites, where cellulose offers flexibility and lignin provides durability.

Methods of Extraction and Processing

Lignin is typically extracted from biomass using chemical processes like kraft pulping or organosolv methods, which break down the lignin structure while preserving cellulose fibers. Cellulose extraction often involves mechanical or enzymatic treatments to separate and purify fibers without degrading their crystalline structure. Understanding these differences in extraction and processing methods can help optimize your use of lignocellulosic biomass for industrial applications.

Industrial Applications: Lignin vs Cellulose

Lignin's robust aromatic polymer structure makes it ideal for industrial applications such as bio-based adhesives, carbon fiber production, and as a renewable precursor for chemicals, while cellulose excels in producing paper, textiles, and biodegradable packaging due to its linear polysaccharide composition. Your choice between lignin and cellulose in industrial processes depends on desired mechanical properties, biodegradability, and chemical reactivity. Cellulose's versatility in forming films and fibers contrasts with lignin's strength and thermal stability, driving distinct applications in sustainable materials development.

Environmental Impact and Sustainability

Lignin and cellulose are critical components in plant biomass with distinct environmental impacts and sustainability profiles. Cellulose, being biodegradable and renewable, supports sustainable practices through efficient recycling and carbon sequestration, making it ideal for eco-friendly materials. Lignin's complex structure poses challenges for biodegradation but offers potential as a renewable source for bio-based products, contributing to waste reduction and sustainable resource utilization.

Challenges in Utilization

Lignin presents challenges in utilization due to its complex, irregular polymer structure, making it difficult to break down and convert into value-added products compared to cellulose, which has a more regular, crystalline structure amenable to enzymatic hydrolysis. The recalcitrance of lignin limits its efficient integration into biofuel production and bioproducts manufacturing, while cellulose's high tensile strength and abundance facilitate its use in biodegradable materials and bioethanol. Overcoming lignin's heterogeneity and resistance to depolymerization remains a critical barrier to advancing biorefinery processes and maximizing biomass valorization.

Future Trends and Innovations

Emerging research in materials science highlights lignin's potential as a sustainable alternative to petroleum-based products due to its abundant availability and biodegradability, driving innovations in bio-based plastics and composites. Advances in enzymatic and chemical modification techniques enhance lignin's compatibility with cellulose, improving the strength and durability of biopolymer materials for packaging and construction. Your investment in technologies harnessing lignin-cellulose synergy could accelerate the transition to circular economies and reduce reliance on non-renewable resources.

Lignin vs Cellulose Infographic

libmatt.com

libmatt.com