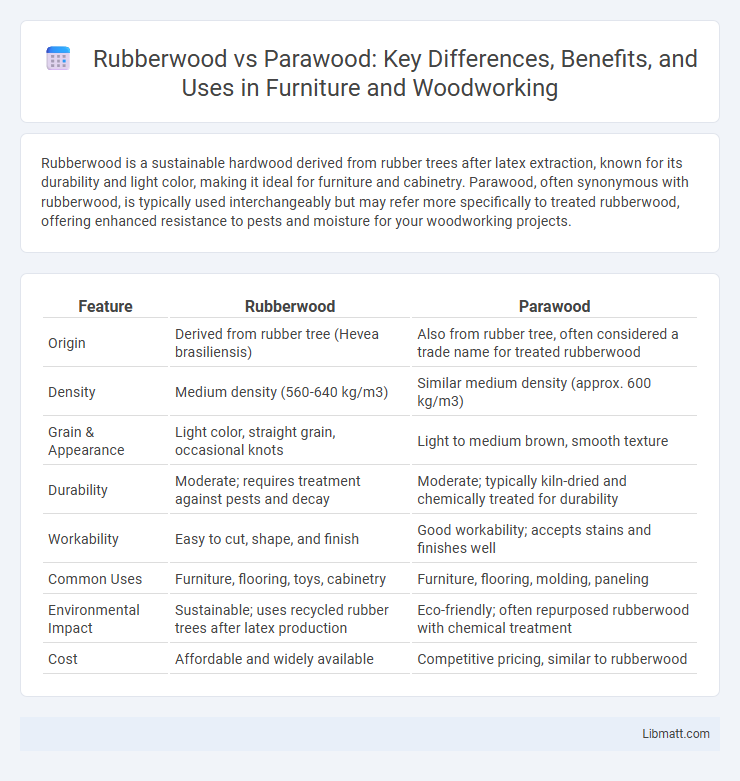

Rubberwood is a sustainable hardwood derived from rubber trees after latex extraction, known for its durability and light color, making it ideal for furniture and cabinetry. Parawood, often synonymous with rubberwood, is typically used interchangeably but may refer more specifically to treated rubberwood, offering enhanced resistance to pests and moisture for your woodworking projects.

Table of Comparison

| Feature | Rubberwood | Parawood |

|---|---|---|

| Origin | Derived from rubber tree (Hevea brasiliensis) | Also from rubber tree, often considered a trade name for treated rubberwood |

| Density | Medium density (560-640 kg/m3) | Similar medium density (approx. 600 kg/m3) |

| Grain & Appearance | Light color, straight grain, occasional knots | Light to medium brown, smooth texture |

| Durability | Moderate; requires treatment against pests and decay | Moderate; typically kiln-dried and chemically treated for durability |

| Workability | Easy to cut, shape, and finish | Good workability; accepts stains and finishes well |

| Common Uses | Furniture, flooring, toys, cabinetry | Furniture, flooring, molding, paneling |

| Environmental Impact | Sustainable; uses recycled rubber trees after latex production | Eco-friendly; often repurposed rubberwood with chemical treatment |

| Cost | Affordable and widely available | Competitive pricing, similar to rubberwood |

Introduction to Rubberwood and Parawood

Rubberwood, derived from the Para rubber tree (Hevea brasiliensis), is a sustainable hardwood widely used in furniture and flooring due to its durability and attractive grain. Parawood, often used interchangeably with rubberwood, specifically refers to treated rubberwood processed to enhance resistance against pests and moisture. When choosing between Rubberwood and Parawood, your decision influences the longevity and maintenance of wooden products in your home.

Origins and Botanical Differences

Rubberwood originates from the Hevea brasiliensis tree, primarily cultivated in Southeast Asia for latex production, whereas Parawood comes from the Paraserianthes falcataria tree, native to the Philippines and Indonesia. Botanically, Rubberwood is a deciduous hardwood characterized by its dense grain and moderate durability, while Parawood is a fast-growing, lightweight hardwood with a looser grain structure. Understanding these species' origins and botanical distinctions helps you select the ideal wood for sustainable furniture and woodworking projects.

Harvesting and Sustainability

Rubberwood is harvested from mature rubber trees (Hevea brasiliensis) after their latex production declines, typically around 25-30 years, utilizing otherwise discarded trees and promoting sustainable land use. Parawood, derived from the Paraserianthes falcataria tree, grows rapidly with a harvesting cycle of 7-10 years, enabling fast replenishment and reducing deforestation pressure. Both woods support eco-friendly forestry practices by maximizing yield and minimizing waste, but rubberwood emphasizes lifecycle utilization, while parawood focuses on quick growth and renewability.

Physical and Mechanical Properties

Rubberwood exhibits higher density and greater strength, making it more durable for furniture and flooring applications compared to parawood, which is lighter and softer. The Janka hardness rating of rubberwood typically ranges around 980 lbf, indicating better resistance to wear and denting than parawood, which has a lower rating. Your choice between the two should consider the balance between strength requirements and weight preferences for the intended use.

Common Applications in Furniture and Industry

Rubberwood is widely used in furniture making due to its durability, resistance to warping, and eco-friendly origin from rubber trees after latex production. Parawood, often sourced from Albizia saman trees, finds common applications in lightweight furniture, interior decor, and small household items because of its softer texture and ease of carving. Your choice between rubberwood and parawood should consider the desired strength, finishing quality, and environmental factors relevant to your furniture or industrial project.

Durability and Lifespan Comparison

Rubberwood offers moderate durability with a lifespan of 10 to 15 years under normal indoor conditions, making it suitable for furniture that experiences regular use. Parawood, known for its hardness and resistance to wear, typically lasts longer, with a lifespan extending up to 20 years, especially when properly treated for moisture and pests. Your choice between these woods should consider the environment and usage intensity to maximize durability and longevity.

Environmental Impact and Eco-Friendliness

Rubberwood, sourced from the Para rubber tree (Hevea brasiliensis), is highly eco-friendly as it utilizes plantation trees after latex extraction, reducing deforestation and supporting sustainable forestry. Parawood, derived from the Albizia tree, is also considered environmentally responsible due to fast growth rates and carbon sequestration benefits, but it is less common and primarily used in furniture production. Both woods offer renewable and biodegradable qualities, with rubberwood having a slight edge in global plantation management practices and reduced chemical treatments.

Cost and Market Availability

Rubberwood generally costs more than parawood due to its higher durability and widespread industrial use, making it a preferred choice in furniture manufacturing. Parawood, being less expensive and less dense, is more readily available in Asian markets but has limited global distribution. Market availability of rubberwood is extensive, supported by sustainable plantation harvesting, while parawood often faces supply constraints outside its primary cultivation regions.

Pros and Cons: Rubberwood vs Parawood

Rubberwood offers durability and resistance to warping, making it ideal for furniture, but it can be prone to insect attacks without proper treatment. Parawood is lightweight and easy to work with, providing smooth finishes for intricate designs, but it is less durable and more susceptible to moisture damage. Both woods require proper maintenance to enhance longevity and performance depending on the application.

Conclusion: Choosing the Right Wood for Your Needs

Rubberwood offers durability and eco-friendliness, making it ideal for furniture and indoor use, while Parawood is valued for its lightweight nature and smooth finish, suitable for craft projects and decorative items. Both woods provide sustainable options derived from rubber tree plantations, but the decision hinges on specific needs such as strength, appearance, and application. Selecting between Rubberwood and Parawood ultimately depends on balancing durability with aesthetics to match the intended functionality.

Rubberwood vs parawood Infographic

libmatt.com

libmatt.com