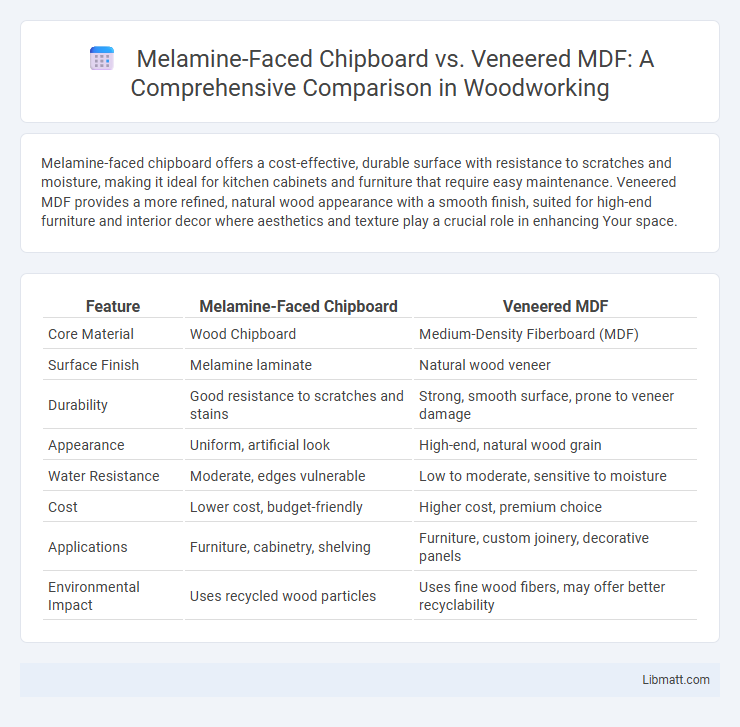

Melamine-faced chipboard offers a cost-effective, durable surface with resistance to scratches and moisture, making it ideal for kitchen cabinets and furniture that require easy maintenance. Veneered MDF provides a more refined, natural wood appearance with a smooth finish, suited for high-end furniture and interior decor where aesthetics and texture play a crucial role in enhancing Your space.

Table of Comparison

| Feature | Melamine-Faced Chipboard | Veneered MDF |

|---|---|---|

| Core Material | Wood Chipboard | Medium-Density Fiberboard (MDF) |

| Surface Finish | Melamine laminate | Natural wood veneer |

| Durability | Good resistance to scratches and stains | Strong, smooth surface, prone to veneer damage |

| Appearance | Uniform, artificial look | High-end, natural wood grain |

| Water Resistance | Moderate, edges vulnerable | Low to moderate, sensitive to moisture |

| Cost | Lower cost, budget-friendly | Higher cost, premium choice |

| Applications | Furniture, cabinetry, shelving | Furniture, custom joinery, decorative panels |

| Environmental Impact | Uses recycled wood particles | Uses fine wood fibers, may offer better recyclability |

Introduction to Melamine-Faced Chipboard and Veneered MDF

Melamine-faced chipboard consists of wood chips bonded with resin and coated with a durable melamine layer, offering moisture resistance and ease of maintenance. Veneered MDF features a smooth medium-density fiberboard core covered with a thin layer of natural wood veneer, providing an authentic wood appearance with enhanced stability. Your choice depends on whether you prioritize durability and cost-effectiveness or a premium, natural wood finish.

Manufacturing Process: Melamine-Faced Chipboard vs Veneered MDF

Melamine-faced chipboard is produced by pressing melamine-impregnated paper onto a chipboard core using heat and pressure, creating a durable, scratch-resistant surface. Veneered MDF involves bonding a thin layer of natural wood veneer onto a medium-density fiberboard core through adhesive application and pressing, preserving the wood grain appearance. The melamine-facing process emphasizes durability and moisture resistance, while veneered MDF focuses on aesthetics and a more refined wood texture.

Surface Quality and Aesthetic Appeal

Melamine-faced chipboard offers a durable, scratch-resistant surface with a consistent, smooth finish ideal for modern, minimalist designs. Veneered MDF provides a richer, natural wood grain appearance with authentic texture, enhancing the aesthetic appeal of luxury furniture. Surface quality in veneered MDF excels in warmth and refinement, while melamine chipboard is preferred for its uniformity and low maintenance.

Durability and Resistance to Wear

Melamine-faced chipboard offers high durability and resistance to scratches, moisture, and heat due to its thermally fused melamine resin surface, making it ideal for heavy-use areas. Veneered MDF provides a smooth, refined finish but is more susceptible to chipping and surface damage under frequent wear since its protective veneer layer is thinner and less resistant. Your choice depends on the balance between wear resistance and aesthetic appeal, with melamine-faced chipboard excelling in long-lasting durability.

Moisture and Heat Resistance

Melamine-faced chipboard offers superior moisture and heat resistance compared to veneered MDF due to its durable melamine resin overlay, which creates a protective surface less prone to swelling and warping. Veneered MDF, while aesthetically pleasing with its natural wood finish, tends to absorb moisture more readily, increasing the risk of damage in humid or high-temperature environments. When selecting materials for areas exposed to moisture or heat, you should consider melamine-faced chipboard for enhanced durability and longevity.

Workability and Ease of Fabrication

Melamine-faced chipboard offers excellent workability with pre-laminated surfaces that reduce the need for finishing, making it ideal for quick fabrication and assembly. Veneered MDF provides smooth, uniform surfaces suitable for intricate detailing and can be sanded or routed easily, though it requires more careful handling to avoid damage to the delicate veneer layer. Both materials support efficient fabrication, but melamine-faced chipboard excels in speed and cost-effectiveness, while veneered MDF allows greater flexibility in detailed woodworking and finishing options.

Cost Comparison: Budget Considerations

Melamine-faced chipboard offers a more affordable option for budget-conscious projects, typically costing less than veneered MDF due to its simpler manufacturing process and lower material expenses. Veneered MDF provides a higher-end finish that mimics natural wood, resulting in increased costs driven by premium materials and labor-intensive application. Your choice hinges on balancing upfront investment with desired aesthetics and durability, where melamine-faced chipboard suits cost-sensitive needs and veneered MDF aligns with premium budget allowances.

Environmental Impact and Sustainability

Melamine-faced chipboard typically has a higher environmental footprint due to the use of synthetic resins and non-renewable adhesives, whereas veneered MDF often utilizes more natural wood veneers, reducing reliance on plastics. Your choice impacts sustainability, as veneered MDF generally offers better recyclability and lowers formaldehyde emissions compared to melamine-faced chipboard. Opting for products certified by organizations like FSC can further enhance environmental responsibility in both materials.

Typical Applications and Use Cases

Melamine-faced chipboard is commonly used in affordable and durable furniture such as kitchen cabinets, office desks, and shelving units due to its moisture resistance and ease of cleaning. Veneered MDF is favored in high-end furniture, decorative panels, and interior doors, offering a premium wood appearance with smooth surface finishes ideal for staining or painting. Both materials suit different needs; melamine-faced chipboard excels in cost-effective, functional environments, while veneered MDF caters to aesthetic-focused applications requiring refined texture and finish.

Choosing the Right Material: Key Factors to Consider

When choosing between melamine-faced chipboard and veneered MDF, factors such as durability, finish quality, and cost play crucial roles. Melamine-faced chipboard offers a hard, scratch-resistant surface ideal for high-traffic areas, while veneered MDF provides a smoother, more aesthetically pleasing surface suitable for premium furniture. Consider moisture resistance and application context to determine the best material for longevity and visual appeal.

Melamine-faced chipboard vs veneered MDF Infographic

libmatt.com

libmatt.com