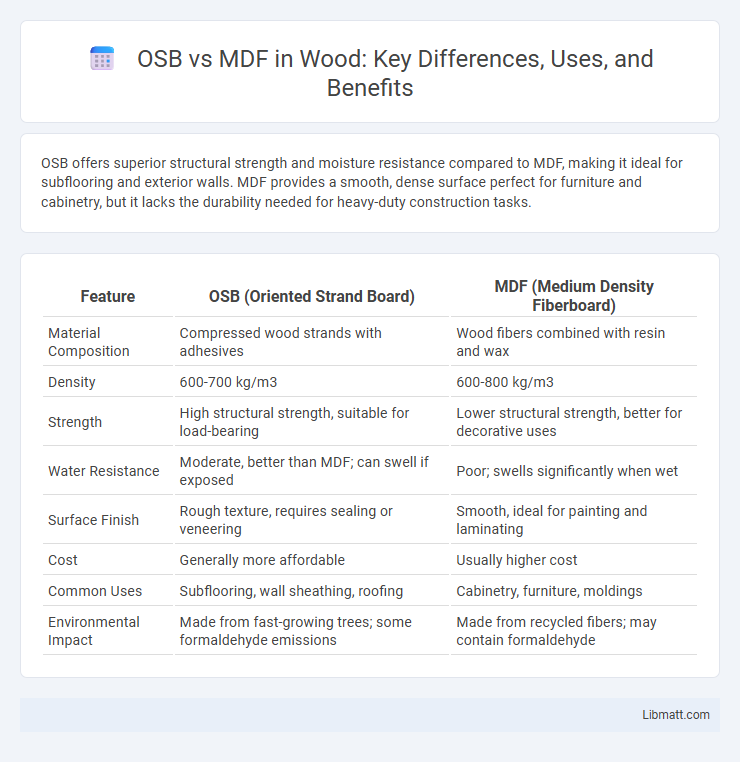

OSB offers superior structural strength and moisture resistance compared to MDF, making it ideal for subflooring and exterior walls. MDF provides a smooth, dense surface perfect for furniture and cabinetry, but it lacks the durability needed for heavy-duty construction tasks.

Table of Comparison

| Feature | OSB (Oriented Strand Board) | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material Composition | Compressed wood strands with adhesives | Wood fibers combined with resin and wax |

| Density | 600-700 kg/m3 | 600-800 kg/m3 |

| Strength | High structural strength, suitable for load-bearing | Lower structural strength, better for decorative uses |

| Water Resistance | Moderate, better than MDF; can swell if exposed | Poor; swells significantly when wet |

| Surface Finish | Rough texture, requires sealing or veneering | Smooth, ideal for painting and laminating |

| Cost | Generally more affordable | Usually higher cost |

| Common Uses | Subflooring, wall sheathing, roofing | Cabinetry, furniture, moldings |

| Environmental Impact | Made from fast-growing trees; some formaldehyde emissions | Made from recycled fibers; may contain formaldehyde |

Introduction to OSB and MDF

Oriented Strand Board (OSB) consists of compressed wood strands arranged in layers, making it strong and water-resistant, ideal for structural applications like flooring and roofing. Medium-Density Fiberboard (MDF) is made from fine wood fibers bonded with resin under heat and pressure, offering a smooth surface perfect for indoor furniture and cabinetry. Understanding the distinct composition and uses of OSB and MDF can help you choose the right material for your building or woodworking projects.

Composition and Manufacturing Processes

Oriented Strand Board (OSB) is made from large wood strands layered in specific orientations and bonded with resin under heat and pressure, giving it strength and durability for structural applications. Medium Density Fiberboard (MDF) consists of fine wood fibers combined with resin and wax, compressed under high pressure to create a smooth, dense panel ideal for detailed cutting and finishing. Your choice between OSB and MDF depends on whether you need structural stability or a smooth surface for aesthetic projects.

Key Physical Properties

OSB (Oriented Strand Board) features a rough texture with visible wood strands compressed in layers, offering strong shear strength and durability ideal for structural applications. MDF (Medium Density Fiberboard) has a smooth, uniform surface made from fine wood fibers bonded with resin, providing excellent machinability and a consistent density that's perfect for detailed finish work. Your choice between OSB and MDF will depend on whether you need robust load-bearing capacity or a smooth surface for painting and cabinetry.

Strength and Durability Comparison

Oriented Strand Board (OSB) offers higher shear strength and greater resistance to impact compared to Medium Density Fiberboard (MDF), making it ideal for structural applications like flooring and wall sheathing. MDF, while smoother and more consistent in density, lacks the robustness needed for heavy load-bearing tasks and is more prone to damage under moisture exposure. OSB's layered strand composition enhances durability and dimensional stability, whereas MDF's fine fibers provide a uniform surface but lower overall strength.

Moisture Resistance and Stability

Oriented Strand Board (OSB) offers superior moisture resistance compared to Medium Density Fiberboard (MDF) due to its larger wood strands and water-resistant adhesives, which help prevent swelling and warping. MDF tends to absorb water more readily, leading to reduced stability and potential deformation when exposed to high humidity or direct moisture. For applications requiring dimensional stability in moist environments, OSB is generally the preferred choice over MDF.

Workability and Ease of Installation

OSB (Oriented Strand Board) is known for its robustness and structural strength but can be more challenging to cut and shape due to its rough texture and dense composition. MDF (Medium Density Fiberboard) offers superior workability with a smooth surface that is easier to cut, shape, and finish, making it ideal for detailed carpentry and cabinetry. Your choice will depend on whether you prioritize ease of installation with MDF or the durability and load-bearing capacity of OSB.

Cost Analysis: OSB vs MDF

Oriented Strand Board (OSB) generally offers a more budget-friendly option compared to Medium Density Fiberboard (MDF), making it ideal for large-scale construction projects or cost-sensitive applications. MDF provides a smoother surface ideal for painting and fine finishes but comes at a higher price point due to its refined manufacturing process. When managing your project's budget, consider that OSB delivers durability and affordability, whereas MDF excels in aesthetic appeal and workability.

Common Applications in Construction and Furniture

OSB (Oriented Strand Board) is widely used in construction for wall sheathing, roof decking, and subflooring due to its strength, moisture resistance, and cost-effectiveness. MDF (Medium Density Fiberboard) excels in furniture making, cabinetry, and interior paneling because of its smooth surface, ease of machining, and ability to hold paint or veneer finishes. Your choice between OSB and MDF depends on whether you prioritize structural durability for building projects or fine surface quality for detailed furniture work.

Environmental Impact and Sustainability

OSB (Oriented Strand Board) is generally considered more environmentally friendly than MDF (Medium Density Fiberboard) because it uses larger wood strands from fast-growing, sustainably managed forests, reducing waste and requiring less energy in production. MDF contains formaldehyde-based resins, which can release harmful VOCs (volatile organic compounds), impacting indoor air quality and environmental health. Choosing OSB for your projects can contribute to sustainability efforts by minimizing toxic emissions and promoting the use of renewable wood resources.

Which to Choose: OSB or MDF?

OSB (Oriented Strand Board) offers superior strength and moisture resistance, making it ideal for structural applications such as subflooring and wall sheathing. MDF (Medium Density Fiberboard) provides a smooth surface with excellent machinability, perfect for indoor furniture, cabinetry, and decorative projects. Choose OSB for durability and outdoor use, while MDF suits detailed finishes and indoor environments.

OSB vs MDF Infographic

libmatt.com

libmatt.com