Soft maple and hard maple differ primarily in density and hardness, with hard maple offering greater durability and resistance to wear, making it ideal for high-traffic areas or heavy-use furniture. You can choose soft maple for projects requiring easier workability and a more affordable option without sacrificing a pleasing grain appearance.

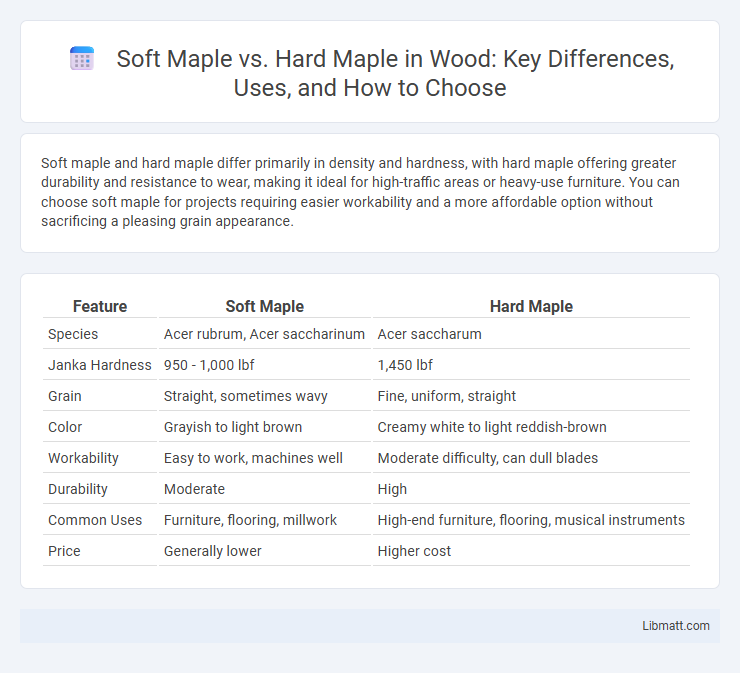

Table of Comparison

| Feature | Soft Maple | Hard Maple |

|---|---|---|

| Species | Acer rubrum, Acer saccharinum | Acer saccharum |

| Janka Hardness | 950 - 1,000 lbf | 1,450 lbf |

| Grain | Straight, sometimes wavy | Fine, uniform, straight |

| Color | Grayish to light brown | Creamy white to light reddish-brown |

| Workability | Easy to work, machines well | Moderate difficulty, can dull blades |

| Durability | Moderate | High |

| Common Uses | Furniture, flooring, millwork | High-end furniture, flooring, musical instruments |

| Price | Generally lower | Higher cost |

Introduction to Soft Maple and Hard Maple

Soft maple and hard maple are two distinct types of maple wood commonly used in furniture and cabinetry, differentiated primarily by their density and grain patterns. Soft maple, including species like red maple and silver maple, is lighter and more pliable, making it easier to work with but less durable than hard maple. Hard maple, often represented by sugar maple, is denser and stronger, offering superior resistance to wear and ideal for high-traffic applications such as flooring and cutting boards.

Botanical Differences Between Soft and Hard Maple

Soft maple primarily refers to species like red maple (Acer rubrum) and silver maple (Acer saccharinum), which belong to the Acer genus but differ in sapwood color and grain structure compared to hard maple. Hard maple encompasses sugar maple (Acer saccharum) and black maple (Acer nigrum), characterized by denser wood and tighter grain due to slower growth in colder climates. Botanical differences hinge on species-specific adaptations affecting wood hardness, color, and microscopic cell structure in the vessels and fibers.

Physical Properties Comparison

Soft maple and hard maple differ significantly in density and grain hardness, with hard maple (Acer saccharum) exhibiting a Janka hardness rating of approximately 1450, making it denser and more durable than soft maple (Acer rubrum or Acer saccharinum), which averages around 950. The higher hardness of hard maple contributes to greater resistance to denting and wear, ideal for flooring and heavy-use furniture, while soft maple, being lighter and less dense, offers easier workability and a softer surface suitable for carving and lighter applications. Both types exhibit similar color ranges from creamy white to light reddish-brown, but hard maple typically has a tighter grain structure, enhancing its strength and stability compared to the more porous and variable texture of soft maple.

Color and Grain Variation

Soft maple typically displays lighter, cream to light brown hues with a more varied, flowing grain pattern, while hard maple features a uniform, pale creamy white color with subtle grain lines. The grain in soft maple is often wavier and more pronounced, creating a distinct textured appearance compared to the fine, consistent grain of hard maple. These color and grain differences influence their aesthetic applications in furniture and cabinetry, where soft maple's variation adds warmth and character, and hard maple offers a sleek, clean look.

Hardness and Durability

Hard maple, also known as sugar maple, has a Janka hardness rating of approximately 1,450 lbf, making it significantly harder and more durable than soft maple, which typically ranges between 700 and 1,100 lbf. This higher hardness translates to greater resistance to dents, scratches, and wear, making hard maple ideal for high-traffic flooring and heavy-use furniture. Soft maple offers easier machinability and a slightly softer surface, but it does not provide the same level of long-term durability as hard maple.

Common Uses in Woodworking

Soft maple wood is commonly used for furniture, cabinetry, and interior millwork due to its smooth grain and ease of staining, making it a budget-friendly alternative to hard maple. Hard maple, with its superior density and durability, is preferred for flooring, cutting boards, and high-traffic areas where wear resistance is critical. Both types are favored in woodworking for their stability and fine finish, but the choice depends on the intended application's strength and appearance requirements.

Workability and Machinability

Soft maple offers superior workability and machinability due to its lower density and softer grain, making it ideal for intricate carving and shaping. Hard maple, while tougher and denser, provides excellent durability but requires sharper tools and more effort during machining. Your choice depends on balancing ease of handling with the desired strength and finish quality for your woodworking project.

Cost and Availability

Soft maple generally costs less than hard maple due to its wider availability and faster growth rate, making it a budget-friendly option for woodworking projects. Hard maple is rarer and more dense, resulting in a higher price but increased durability and strength. Your choice between the two will depend on balancing cost considerations with the specific requirements of your project.

Choosing the Right Maple for Your Project

Soft maple offers easier workability and lower cost, making it ideal for crafting furniture, cabinetry, and decorative items where intricate shaping is required. Hard maple provides exceptional strength and durability, perfect for flooring, cutting boards, and heavy-use surfaces that demand resistance to wear and impact. Consider your project's functional needs and budget to select the right maple species that balances aesthetic appeal with performance.

Summary: Key Differences and Recommendations

Soft maple features a lighter weight and easier workability due to its lower density, making it ideal for furniture, veneers, and interior projects requiring intricate carving. Hard maple, recognized for its superior hardness and durability with a Janka hardness rating around 1450 lbf, is preferred for flooring, countertops, and heavy-use items demanding high resistance to wear. Choose soft maple for cost-effective, decorative purposes, and hard maple for applications requiring strength and long-lasting performance.

Soft maple vs hard maple Infographic

libmatt.com

libmatt.com