MDO plywood features a smooth, paintable surface with a resin-impregnated overlay, ideal for exterior signage and applications requiring durable finishes, while HDO plywood boasts a harder, more wear-resistant phenolic film overlay suited for concrete forming and heavy-duty uses. Your choice depends on whether you need a high-quality paint surface (MDO) or a rugged, reusable formwork material (HDO).

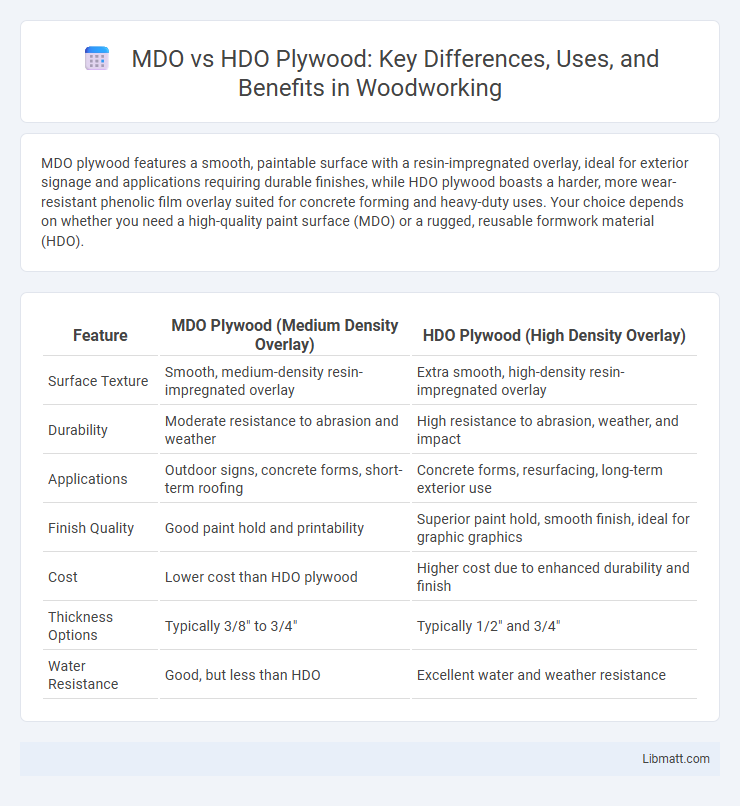

Table of Comparison

| Feature | MDO Plywood (Medium Density Overlay) | HDO Plywood (High Density Overlay) |

|---|---|---|

| Surface Texture | Smooth, medium-density resin-impregnated overlay | Extra smooth, high-density resin-impregnated overlay |

| Durability | Moderate resistance to abrasion and weather | High resistance to abrasion, weather, and impact |

| Applications | Outdoor signs, concrete forms, short-term roofing | Concrete forms, resurfacing, long-term exterior use |

| Finish Quality | Good paint hold and printability | Superior paint hold, smooth finish, ideal for graphic graphics |

| Cost | Lower cost than HDO plywood | Higher cost due to enhanced durability and finish |

| Thickness Options | Typically 3/8" to 3/4" | Typically 1/2" and 3/4" |

| Water Resistance | Good, but less than HDO | Excellent water and weather resistance |

Introduction to MDO and HDO Plywood

MDO (Medium Density Overlay) and HDO (High Density Overlay) plywood are engineered wood panels coated with resin-impregnated overlays for enhanced durability and surface smoothness. MDO plywood features a medium-density resin overlay ideal for paint adhesion and moderate weather resistance, making it suitable for signage and carpentry projects. HDO plywood offers a smoother, harder surface with a high-density resin overlay, providing superior durability and moisture resistance, perfect for concrete formwork and exterior applications where longevity is critical.

What Is MDO Plywood?

MDO plywood, or Medium Density Overlay plywood, features a resin-impregnated fiber surface bonded to a high-quality veneer core, providing enhanced smoothness and durability compared to standard plywood. It is specifically designed for exterior applications such as signage and concrete formwork, offering superior resistance to moisture, UV rays, and wear. The overlay improves paint adhesion and extends the lifespan of the plywood in harsh environmental conditions.

What Is HDO Plywood?

HDO plywood, or High-Density Overlay plywood, features a resin-impregnated fiber surface that provides exceptional durability and a smooth, high-gloss finish, ideal for concrete formwork and outdoor applications. Its laminated phenolic film resists moisture, abrasion, and chemicals, enhancing the board's longevity in demanding environments. Compared to Medium-Density Overlay (MDO) plywood, HDO offers a denser, harder surface better suited for heavy-duty uses requiring superior wear resistance and surface integrity.

Differences Between MDO and HDO Plywood

MDO plywood features a smooth, paint-grade surface made by bonding a resin-impregnated overlay onto a plywood core, ideal for signage and outdoor projects requiring a high-quality finish. HDO plywood utilizes a denser, harder phenolic resin overlay, providing superior durability, water resistance, and a longer-lasting smooth surface, often used in concrete forms and heavy-duty applications. Understanding these differences helps you select the right plywood for your project's durability and aesthetic needs.

Manufacturing Process: MDO vs HDO

MDO plywood (Medium Density Overlay) undergoes a manufacturing process where a medium-density fiberboard veneer is bonded to the plywood surface using resin, creating a smooth and paintable finish ideal for outdoor use. HDO plywood (High Density Overlay) features a manufacturing process that involves applying a high-density fiberboard veneer saturated with phenolic resin, offering superior durability, water resistance, and a hard, smooth surface suitable for heavy-duty applications. Both processes enhance plywood performance, but HDO's resin saturation and higher density provide increased strength and weather resistance compared to MDO.

Strength and Durability Comparison

MDO plywood features a phenolic film overlay that enhances its resistance to moisture and abrasion, making it stronger and more durable for outdoor and heavy-duty applications compared to HDO plywood. HDO plywood has a smoother and harder surface finish, ideal for producing high-quality concrete forms, but it may be less resistant to long-term exposure to harsh weather conditions than MDO. Your choice between MDO and HDO plywood should consider the required strength, durability, and environmental exposure of your specific project.

Surface Finish and Paintability

MDO (Medium Density Overlay) plywood features a smooth, resin-impregnated fiber overlay that provides an excellent surface finish ideal for high-quality paint applications, ensuring durability and a professional look. HDO (High Density Overlay) plywood offers an even smoother, more uniform surface with a harder overlay layer, making it particularly suitable for demanding exterior paint jobs requiring superior weather resistance. Your choice between MDO and HDO affects paint adhesion and longevity, with HDO generally delivering better protection and a longer-lasting finish.

Common Applications of MDO and HDO

MDO (Medium Density Overlay) plywood is commonly used for projects that require a smooth, paintable surface, such as outdoor signage, concrete formwork, and cabinet doors. HDO (High Density Overlay) plywood offers a tougher, more durable surface ideal for long-term outdoor applications like highway signs, exterior siding, and industrial concrete forms. Understanding the differences allows you to select the right plywood for your specific project needs, balancing cost and durability.

Cost Considerations: MDO vs HDO

MDO (Medium Density Overlay) plywood is generally more cost-effective than HDO (High Density Overlay) plywood due to its thinner resin overlay and lower density, making it suitable for budget-conscious projects requiring moderate durability. HDO plywood features a thicker, high-density resin overlay that delivers superior resistance to weather, abrasion, and wear, justifying its higher price in applications demanding long-term performance and heavy-duty use. Choosing between MDO and HDO hinges on balancing upfront material costs with the expected lifespan and environmental exposure of the plywood in construction or signage projects.

Choosing the Right Plywood: MDO or HDO

Choosing between MDO (Medium Density Overlay) and HDO (High Density Overlay) plywood depends on project requirements such as durability and finish quality. MDO plywood offers a smooth surface suitable for painting and is ideal for outdoor signs and temporary concrete forms, while HDO plywood provides superior density and wear resistance, making it perfect for heavy-duty concrete forming and long-lasting applications. Understanding the differences in overlay density and coating materials ensures the right plywood choice for structural integrity and aesthetic needs.

MDO vs HDO plywood Infographic

libmatt.com

libmatt.com