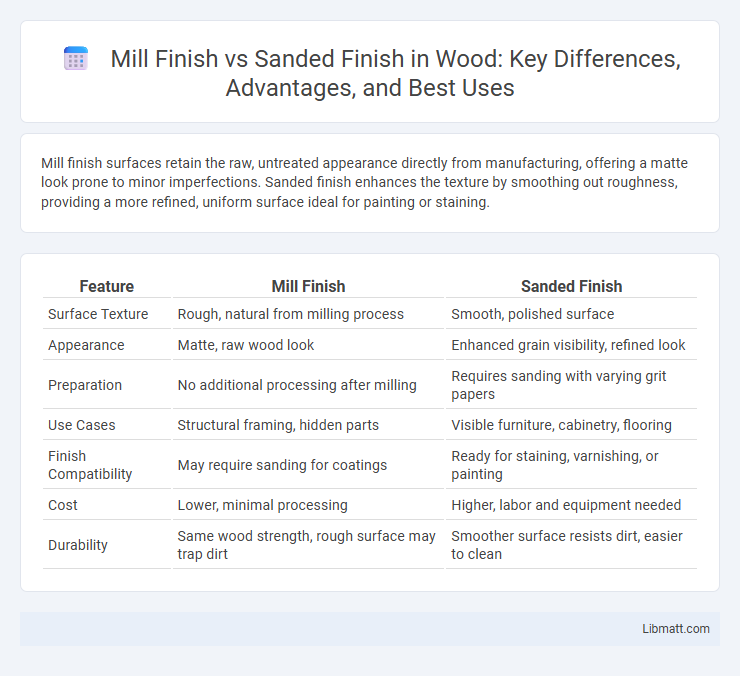

Mill finish surfaces retain the raw, untreated appearance directly from manufacturing, offering a matte look prone to minor imperfections. Sanded finish enhances the texture by smoothing out roughness, providing a more refined, uniform surface ideal for painting or staining.

Table of Comparison

| Feature | Mill Finish | Sanded Finish |

|---|---|---|

| Surface Texture | Rough, natural from milling process | Smooth, polished surface |

| Appearance | Matte, raw wood look | Enhanced grain visibility, refined look |

| Preparation | No additional processing after milling | Requires sanding with varying grit papers |

| Use Cases | Structural framing, hidden parts | Visible furniture, cabinetry, flooring |

| Finish Compatibility | May require sanding for coatings | Ready for staining, varnishing, or painting |

| Cost | Lower, minimal processing | Higher, labor and equipment needed |

| Durability | Same wood strength, rough surface may trap dirt | Smoother surface resists dirt, easier to clean |

Understanding Mill Finish: Definition and Characteristics

Mill finish refers to the raw, untreated surface of metal products as they come directly from the manufacturing process, characterized by a rough, dull appearance with visible machining marks. This finish lacks any additional polishing or sanding, resulting in natural oxide layers that can affect corrosion resistance and surface texture. Understanding the mill finish helps you determine whether further sanding or finishing is necessary for your project's aesthetic and functional requirements.

What is Sanded Finish? Key Features Explained

Sanded finish refers to a surface texture achieved by mechanically smoothing materials, typically metals or wood, using abrasive tools to create a uniform, matte appearance. This finish enhances grip, reduces glare, and provides a consistent base for further coatings or treatments. Your choice of sanded finish ensures improved aesthetic appeal and functional performance compared to the raw, unprocessed mill finish.

Differences in Manufacturing Processes

Mill finish surfaces are produced directly from the extrusion or rolling process, often retaining the natural texture and minor imperfections of the metal without additional surface treatment. Sanded finish involves a secondary manufacturing process where abrasive materials are used to create a uniform, smooth texture by removing surface irregularities, enhancing both appearance and corrosion resistance. The mill finish is quicker and less costly, whereas the sanded finish requires more labor and equipment, resulting in a refined aesthetic and functional improvement.

Surface Appearance: Mill Finish vs Sanded Finish

Mill finish exhibits a raw, metallic look with visible machining marks and a slightly rough texture, reflecting its untreated state after extrusion or casting. Sanded finish offers a smooth, refined surface achieved through abrasive sanding techniques, enhancing the material's visual appeal and tactile quality. Your choice between mill finish and sanded finish impacts the aesthetic and feel of the final product, influencing both design and functional applications.

Texture and Smoothness Comparison

Mill finish surfaces exhibit a rougher texture with visible machining marks, offering minimal smoothness due to the absence of additional finishing processes. Sanded finish surfaces undergo abrasive treatment that removes imperfections, resulting in a uniformly smooth and matte texture that enhances tactile quality and visual appeal. The sanded finish significantly reduces surface roughness compared to mill finish, making it ideal for applications requiring improved aesthetics and handling.

Durability and Resistance Factors

Mill finish aluminum offers moderate durability with its as-extruded surface, but it is more prone to scratches, corrosion, and oxidation over time compared to sanded finish. Sanded finish enhances resistance by creating a uniform texture that helps mask surface imperfections and reduces the visibility of wear and tear, improving long-term aesthetics and protection. Your choice between these finishes should consider the environmental exposure and desired lifespan of the material, as sanded finishes provide superior durability and corrosion resistance for challenging conditions.

Best Applications for Mill Finish

Mill finish surfaces are ideal for applications where cost-efficiency and subsequent custom finishing are priorities, such as in construction framing, automotive parts, and industrial equipment. This finish maintains the material's natural state directly from the manufacturing process, making it suitable for components that will undergo further machining, welding, or coating. Mill finish aluminum, steel, and other metals are commonly used in structural frameworks and prototypes where surface appearance is secondary to structural integrity.

Ideal Uses for Sanded Finish

Sanded finish is ideal for applications requiring enhanced grip and slip resistance, such as stair treads, flooring, and outdoor walkways. Its textured surface improves safety in industrial and commercial settings where moisture or oils may be present. This finish also works well for decorative architectural elements, providing a matte appearance that reduces glare and fingerprints.

Cost Implications and Value Comparison

Mill finish typically costs less than sanded finish due to minimal processing and surface treatment, making it an economical choice for projects with tight budgets. Sanded finish involves additional labor and equipment to smooth and refine surfaces, increasing overall expenses while enhancing aesthetic appeal and tactile quality. Your decision should weigh the balance between upfront cost savings of mill finish and the long-term value gained from sanded finish's improved durability and visual impact.

Choosing the Right Finish: Factors to Consider

Choosing the right finish between mill finish and sanded finish depends on factors such as the desired aesthetic, surface smoothness, and environmental exposure. Mill finish offers a raw, industrial look with minimal processing, suitable for applications where functionality outweighs appearance, while sanded finish provides a smoother, more refined surface ideal for painting or decorative use. Consider the project's durability requirements, corrosion resistance, and maintenance needs when selecting the appropriate finish for optimal performance.

Mill finish vs Sanded finish Infographic

libmatt.com

libmatt.com