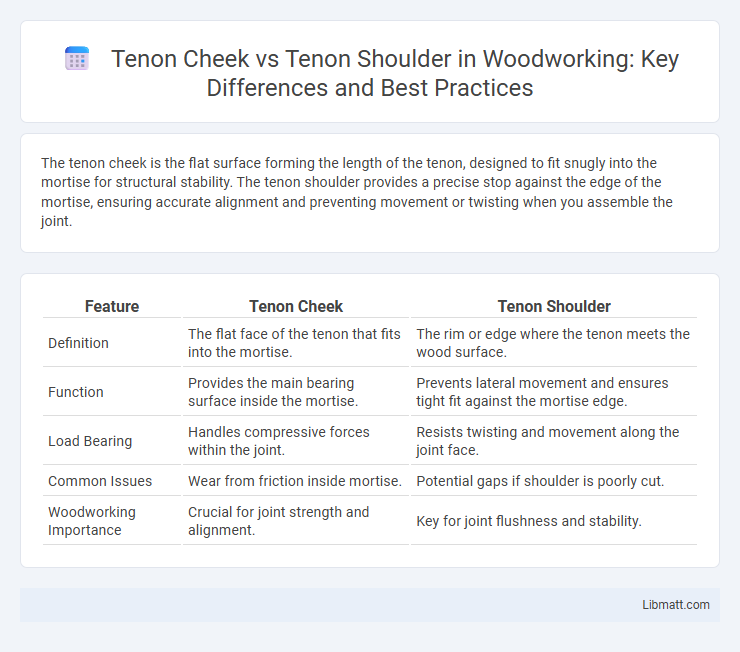

The tenon cheek is the flat surface forming the length of the tenon, designed to fit snugly into the mortise for structural stability. The tenon shoulder provides a precise stop against the edge of the mortise, ensuring accurate alignment and preventing movement or twisting when you assemble the joint.

Table of Comparison

| Feature | Tenon Cheek | Tenon Shoulder |

|---|---|---|

| Definition | The flat face of the tenon that fits into the mortise. | The rim or edge where the tenon meets the wood surface. |

| Function | Provides the main bearing surface inside the mortise. | Prevents lateral movement and ensures tight fit against the mortise edge. |

| Load Bearing | Handles compressive forces within the joint. | Resists twisting and movement along the joint face. |

| Common Issues | Wear from friction inside mortise. | Potential gaps if shoulder is poorly cut. |

| Woodworking Importance | Crucial for joint strength and alignment. | Key for joint flushness and stability. |

Introduction to Tenon Joints

Tenon cheek refers to the flat surfaces on the sides of the tenon, which engage with the mortise walls providing lateral stability in a tenon joint. Tenon shoulder is the face of the tenon that rests flush against the surface of the mortise piece, offering alignment and resisting twisting forces. Both components are critical for ensuring a strong, precise dovetail or mortise-and-tenon joint in woodworking and furniture making.

What Is a Tenon Cheek?

A Tenon cheek refers to the flat, broad surfaces on the sides of a tenon that fit snugly into the mortise, providing the majority of the joint's strength and stability. These cheeks are crucial for distributing stress evenly and preventing the joint from twisting or loosening over time. Compared to the Tenon shoulder, which is the edge that rests against the mortise entrance and helps with alignment, the tenon cheek carries more load and plays a larger role in mechanical integrity.

What Is a Tenon Shoulder?

A tenon shoulder is the flat, perpendicular surface on a tenon that provides a precise stop when the tenon is inserted into a mortise, ensuring a tight and flush joint. It helps align the adjoining pieces and distributes stress evenly, enhancing the structural integrity of the woodworking joint. Unlike the tenon cheek, which forms the main thickness of the tenon, the shoulder acts as a critical reference surface for accurate fitting and stability.

Purpose of Tenon Cheeks in Joinery

Tenon cheeks are the flat surfaces on either side of the tenon that provide the main bearing area for the joint, ensuring a strong mechanical connection with the corresponding mortise walls. Their purpose is to increase the glue surface area and resist lateral stresses, enhancing the joint's durability and stability. You rely on well-crafted tenon cheeks to maintain structural integrity in frames and furniture assemblies.

Role of Tenon Shoulders in Structural Strength

Tenon shoulders provide critical lateral support to woodworking joints by preventing lateral movement and ensuring tight fits between connected pieces. The shoulders distribute loads evenly around the joint, enhancing overall structural integrity and resistance to twisting forces. Compared to the cheek, which primarily fits into the mortise, the shoulder's role in stabilizing and maintaining alignment is essential for durable, load-bearing connections.

Key Differences: Tenon Cheek vs Tenon Shoulder

The key differences between the tenon cheek and tenon shoulder lie in their positioning and function within woodworking joints. The tenon cheek is the flat, elongated face of the tenon that fits into the mortise, providing most of the joint's bonding surface and strength. The tenon shoulder, located at the junction where the tenon meets the parent wood, ensures alignment and prevents lateral movement, contributing to the overall stability of the joint.

Impact on Fitting and Assembly

Tenon cheek and tenon shoulder both significantly influence fitting and assembly in woodworking, with the tenon shoulder providing a crucial bearing surface that enhances joint alignment and stability. The tenon cheek affects the mechanical strength and snugness of fit within the mortise, ensuring minimal movement and durability under load. Properly dimensioned cheeks and shoulders are essential for achieving a precise, tight joint, reducing gaps and improving overall structural integrity.

Common Mistakes with Cheeks and Shoulders

Common mistakes with Tenon cheeks include uneven or inconsistent thickness, which compromises joint strength and alignment. Errors with Tenon shoulders often involve insufficient shoulder width, leading to weak shoulders that fail to properly support the mortise. Ensuring your cheeks are cleanly pared and shoulders are square prevents gaps and misfits in mortise and tenon joints.

Best Practices for Cutting Tenon Cheeks and Shoulders

Cutting tenon cheeks requires precise measurement and smooth, consistent cuts to ensure a snug fit within the mortise, often achieved using a rip saw or a tenon saw with steady, controlled strokes. When shaping tenon shoulders, accurate marking and clean, square cuts prevent gaps and maintain joint strength, typically done with a tenon saw or a bevel gauge for perfect angles. Focus on maintaining sharp tools and stable workpieces to improve accuracy in both tenon cheeks and shoulders, enhancing the overall fit and durability of your woodworking joints.

Conclusion: Optimizing Tenon Joints for Woodworking

Tenon cheek and tenon shoulder both play critical roles in the strength and stability of woodworking joints. The tenon cheek, being the larger surface area, provides the main adhesion surface for glue, while the tenon shoulder offers precise alignment and resists twisting forces. Optimizing your tenon joints requires balancing these two features to ensure a durable, well-fitted connection that enhances the overall quality of your woodworking project.

Tenon cheek vs Tenon shoulder Infographic

libmatt.com

libmatt.com