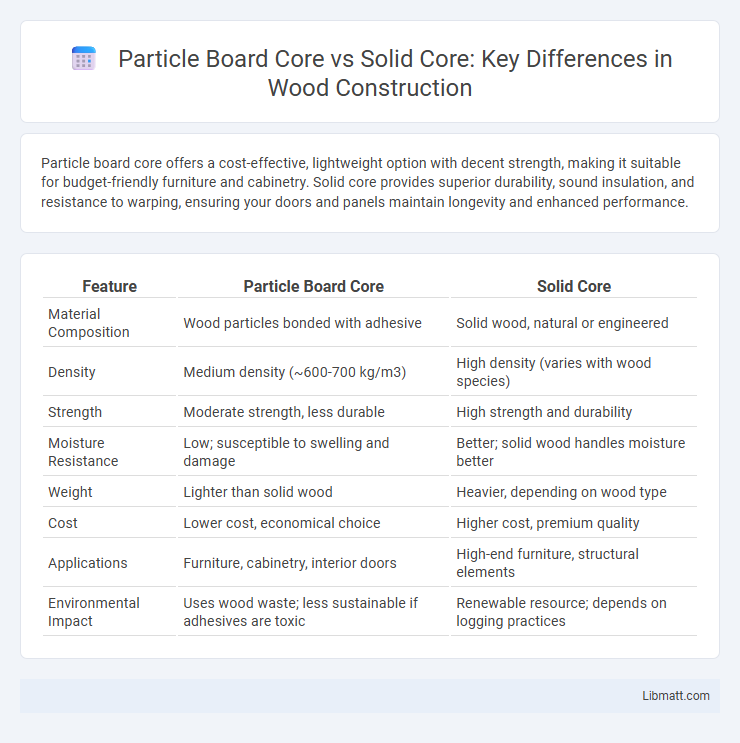

Particle board core offers a cost-effective, lightweight option with decent strength, making it suitable for budget-friendly furniture and cabinetry. Solid core provides superior durability, sound insulation, and resistance to warping, ensuring your doors and panels maintain longevity and enhanced performance.

Table of Comparison

| Feature | Particle Board Core | Solid Core |

|---|---|---|

| Material Composition | Wood particles bonded with adhesive | Solid wood, natural or engineered |

| Density | Medium density (~600-700 kg/m3) | High density (varies with wood species) |

| Strength | Moderate strength, less durable | High strength and durability |

| Moisture Resistance | Low; susceptible to swelling and damage | Better; solid wood handles moisture better |

| Weight | Lighter than solid wood | Heavier, depending on wood type |

| Cost | Lower cost, economical choice | Higher cost, premium quality |

| Applications | Furniture, cabinetry, interior doors | High-end furniture, structural elements |

| Environmental Impact | Uses wood waste; less sustainable if adhesives are toxic | Renewable resource; depends on logging practices |

Understanding Particle Board Core

Particle board core offers a cost-effective, lightweight alternative to solid core, composed of compressed wood particles bonded with resin for enhanced stability and resistance to warping. It excels in applications where affordability and consistent thickness are critical but may lack the durability and sound insulation of solid core materials. Understanding particle board core helps in selecting the right material for furniture, cabinetry, or door construction, balancing price and performance needs.

What is Solid Core?

Solid core refers to a material construction where the interior is made entirely of a dense, uniform substance such as solid wood, medium-density fiberboard (MDF), or high-density particleboard, providing strength and durability. Unlike particle board core, which consists of compressed wood particles, a solid core offers superior sound insulation, resistance to warping, and enhanced structural integrity. This makes solid core doors and panels ideal for applications requiring robustness and better thermal and acoustic performance.

Material Composition Comparison

Particle board core consists of compressed wood particles bonded with resin, offering a cost-effective and lightweight option often used in furniture manufacturing. Solid core is made from a solid piece of wood or engineered wood layers, providing superior strength, durability, and resistance to warping. The difference in material composition directly impacts the core's density, weight capacity, and overall performance in construction or cabinetry applications.

Weight and Density Differences

Particle board core typically has a lower density and weight compared to solid core materials, making it lighter and easier to handle in furniture manufacturing. Solid core boards, made from dense hardwood or MDF, offer enhanced durability and structural integrity due to their higher mass and compact composition. The significant difference in density impacts not only the weight but also the sound insulation and resistance to wear in applications such as doors and cabinetry.

Durability and Lifespan

Particle board core offers moderate durability but is more prone to moisture damage and structural weakening over time compared to solid core materials. Solid core construction provides superior strength, resistance to warping, and a longer lifespan, making it ideal for high-traffic or heavy-use applications. The density and inherent stability of solid core boards significantly enhance durability, supporting greater longevity in furniture and cabinetry.

Sound Insulation Properties

Particle board core offers moderate sound insulation properties due to its denser composition, effectively dampening noise transmission in interior doors. Solid core doors provide superior soundproofing by incorporating a homogenous, solid material that blocks and absorbs sound waves more efficiently. Choosing a solid core door enhances your space's acoustic privacy and reduces noise disturbance significantly.

Cost Comparison

Particle board core panels typically offer a more budget-friendly option compared to solid core panels, making them popular for cost-conscious projects. The manufacturing process of particle board utilizes compressed wood particles and resin, resulting in lower material costs than the dense, natural wood used in solid core construction. While solid core panels provide superior durability and sound insulation, particle board cores deliver an effective balance between performance and affordability for interior applications.

Environmental Impact

Particle board core typically has a lower environmental impact compared to solid core due to its use of recycled wood fibers and wood waste, reducing the demand for virgin timber. Solid core materials, often sourced from hardwoods, contribute to deforestation and higher carbon emissions during production. Choosing particle board core for Your furniture supports sustainability by promoting resource efficiency and waste minimization.

Best Applications for Each Core

Particle board core is ideal for budget-friendly furniture, cabinetry, and interior doors where cost efficiency and moderate durability are essential, making it perfect for residential and light commercial use. Solid core provides superior strength, sound insulation, and durability, best suited for exterior doors, high-traffic areas, and environments requiring enhanced security and moisture resistance. Choosing the right core depends on Your project's demand for load-bearing capacity, visual appeal, and long-term performance.

Choosing the Right Core for Your Needs

Particle board core offers affordability and lightweight properties, making it ideal for budget-conscious projects and furniture that requires easy maneuverability. Solid core provides superior durability, soundproofing, and resistance to impact, perfect for high-traffic areas or doors exposed to frequent use. Understanding your specific requirements for strength, cost, and maintenance will help you choose the core material that best suits your needs.

Particle board core vs solid core Infographic

libmatt.com

libmatt.com