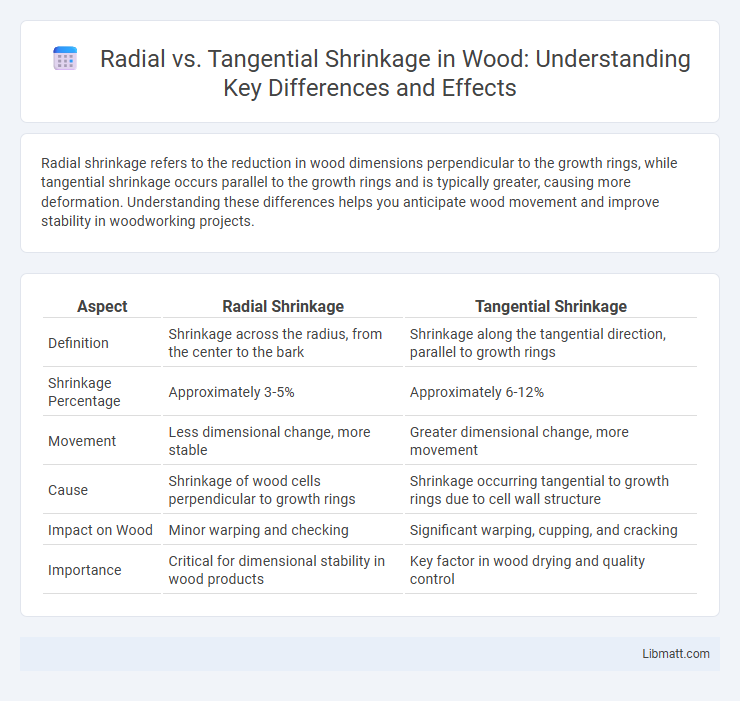

Radial shrinkage refers to the reduction in wood dimensions perpendicular to the growth rings, while tangential shrinkage occurs parallel to the growth rings and is typically greater, causing more deformation. Understanding these differences helps you anticipate wood movement and improve stability in woodworking projects.

Table of Comparison

| Aspect | Radial Shrinkage | Tangential Shrinkage |

|---|---|---|

| Definition | Shrinkage across the radius, from the center to the bark | Shrinkage along the tangential direction, parallel to growth rings |

| Shrinkage Percentage | Approximately 3-5% | Approximately 6-12% |

| Movement | Less dimensional change, more stable | Greater dimensional change, more movement |

| Cause | Shrinkage of wood cells perpendicular to growth rings | Shrinkage occurring tangential to growth rings due to cell wall structure |

| Impact on Wood | Minor warping and checking | Significant warping, cupping, and cracking |

| Importance | Critical for dimensional stability in wood products | Key factor in wood drying and quality control |

Understanding Wood Shrinkage: Radial vs Tangential

Wood shrinkage varies significantly between radial and tangential directions, with tangential shrinkage typically being 5 to 10% greater than radial due to the orientation of wood fibers and cellular structure. Radial shrinkage occurs perpendicular to the growth rings, leading to more uniform dimensional changes, whereas tangential shrinkage occurs along the growth rings, causing greater distortion and potential warping. Understanding these differences is crucial for woodworking, furniture making, and construction to minimize defects during drying and maintain structural integrity.

Key Differences Between Radial and Tangential Shrinkage

Radial shrinkage occurs along the radius of a tree, perpendicular to the growth rings, typically ranging from 2% to 5%, while tangential shrinkage happens parallel to the growth rings and is usually higher, between 6% and 12%. The key difference lies in their directional growth patterns, with tangential shrinkage causing more dimensional change and potential warping because it affects the wider circumference. Understanding these differences is crucial for woodworking and lumber processing to minimize deformation and ensure structural stability.

The Science Behind Wood Fiber Orientation

Wood fiber orientation significantly influences radial and tangential shrinkage, with radial shrinkage occurring perpendicular to the growth rings and tangential shrinkage parallel to them. Tangential shrinkage is typically twice as large as radial due to fiber arrangement and the presence of rays that restrict radial contraction. Understanding the microstructural differences helps predict dimensional stability and performance in various wood applications.

Measuring Radial and Tangential Shrinking in Timber

Measuring radial and tangential shrinkage in timber involves assessing dimensional changes perpendicular to and along the growth rings, respectively. Radial shrinkage occurs across the radius from the heartwood to the bark, typically showing less percentage of contraction than tangential shrinkage, which happens parallel to the growth rings. Accurate measurement includes using moisture content data and dimensional changes before and after drying to determine shrinkage rates, which are critical for predicting wood stability and performance in construction and manufacturing.

Factors Influencing Shrinkage Rates

Factors influencing radial vs tangential shrinkage rates primarily include wood species, moisture content, and grain orientation. Tangential shrinkage tends to be about twice as much as radial shrinkage due to the arrangement of wood fibers and rays. Your understanding of these factors is crucial for applications requiring dimensional stability in wood products.

Impact of Shrinkage on Wood Stability

Radial shrinkage occurs perpendicular to the growth rings, while tangential shrinkage occurs parallel, with tangential shrinkage typically being twice as large, leading to greater dimensional changes. This differential shrinkage creates internal stresses and warping, significantly impacting wood stability and usability in construction and woodworking. Understanding these shrinkage patterns helps in selecting wood species and drying methods to minimize cracking, cupping, and distortion.

Practical Implications for Woodworking and Construction

Radial shrinkage in wood causes less dimensional change compared to tangential shrinkage, which is nearly twice as large, significantly impacting stability in woodworking and construction projects. Understanding these differences helps professionals choose wood orientation wisely to minimize warping, cracking, and joint failure in furniture making or structural applications. Proper grain alignment and allowance for shrinkage variations ensure long-term durability and precise fitting of wooden components.

Strategies to Minimize Shrinkage Effects

To minimize radial and tangential shrinkage effects in wood, controlling moisture content through proper drying techniques such as kiln drying is essential. Applying sealants or stabilizers can further reduce uneven shrinkage by maintaining dimensional stability. You can also select wood species with lower inherent shrinkage rates and orient cuts strategically to optimize structural integrity.

Choosing the Right Wood for Dimensional Stability

Radial shrinkage occurs perpendicular to the growth rings, while tangential shrinkage runs parallel, often causing more significant dimensional changes in wood. When prioritizing dimensional stability, selecting wood species with minimal tangential shrinkage reduces warping and cracking in your projects. Understanding the differential shrinkage values allows you to choose the best wood to maintain structural integrity and appearance over time.

Conclusion: Optimizing Material Selection Through Shrinkage Knowledge

Understanding radial vs tangential shrinkage is crucial for selecting wood materials with dimensional stability, as radial shrinkage typically ranges from 3% to 7% while tangential shrinkage can be 5% to 10%, significantly affecting warp and distortion risks. By accurately assessing these anisotropic shrinkage properties, engineers and woodworkers can optimize material choice to minimize structural deformation in applications such as furniture, flooring, and construction. Leveraging shrinkage data enhances durability and performance by ensuring the wood's behavior under moisture variation aligns with specific design requirements.

Radial vs tangential shrinkage Infographic

libmatt.com

libmatt.com